Quick Leads-PCBA

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Choosing the right EMS partner for wearables isn’t easy.

Engineers and product teams are under pressure to launch smarter, lighter, and faster wearable devices—without waiting months or ordering 10,000 units. Yet most EMS providers still demand high MOQs or lack technical flexibility. This guide cuts through the noise and highlights EMS companies built for 2025’s wearable tech demands.

The top EMS companies for wearable electronics in 2025 offer fast prototyping, no minimum order quantities (MOQ), turnkey assembly, and advanced capabilities in flexible PCB assembly, sensor integration, and post-soldering testing. Industry leaders include Jabil, Flex, Sanmina, and specialized providers in China and the U.S. that cater to low-volume, high-mix wearable projects with a focus on quality, speed, and design-for-manufacturing (DFM) insights.

Let’s explore what sets these EMS providers apart and how they solve industry pain points—from SMT bottlenecks to the benefits of panelization for scaling wearable device production.

What is the world’s number one EMS company?

Foxconn remains the largest EMS provider globally, handling everything from smartphones to consumer electronics. But for wearables, size isn’t everything. Smaller, more agile providers often outperform giants in areas like flexible PCB assembly, no-MOQ prototyping, and DFM support for AIoT modules.

So while Foxconn leads in revenue, it doesn’t always lead in wearable innovation.

Top 10 EMS Companies for Wearable Electronics in 2025

Here’s a curated list based on capabilities in wearable prototyping, flexibility, sensor integration, and global fulfillment:

-

Jabil (USA) – Wearable product design + scalable prototyping

-

Flex (Singapore/USA) – Strong in health, fitness, and AIoT wearable EMS

-

Sanmina (USA) – Medical wearables with FDA-compliant processes

-

Plexus (USA) – Complex, compact PCB assembly + validation services

-

Zollner Elektronik (Germany) – High-quality small-batch medical EMS

-

GOERTEK (China) – OEM for audio + wearable sensor integration

-

Kaifa Technology (China) – High-mix low-volume production expertise

-

RayMing Tech (China) – Fast prototyping + flexible circuit assembly

-

MacroFab (USA) – Startup-friendly cloud-based EMS + no MOQ

-

Venture Electronics (China) – One-stop service with SMT + post-soldering services

✅ Note: If you want to feature your company here, we can edit one of these entries for positioning.

Turnkey PCB Assembly for Wearable Devices: What to Expect

Turnkey means you don’t just get PCB assembly—you get:

-

Component sourcing (including ultra-compact sensors)

-

SMT + DIP assembly for flex-rigid boards

-

Automated optical inspection (AOI)

-

Post-soldering testing for real-world reliability

-

Final assembly into wearable enclosures

This is critical for startups, where agility matters more than volume.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Pain Points in SMT Placement for Wearables — and How to Fix Them

Wearables use tiny components, tight layouts, and often flexible substrates. Here are common SMT issues:

| Problem | Solution |

|---|---|

| 01005 passive misalignment | Precision pick-and-place + optical inspection |

| Tombstoning | Reflow profiling + solder paste optimization |

| Incomplete wetting | Preheat control + solder paste selection |

| Cracking on flex PCBs | Use panelization and reduce mechanical stress during handling |

By integrating SMT + post-soldering QA, top EMS providers ensure signal integrity, mechanical strength, and performance under sweat, heat, and motion.

Post-Soldering Services in Wearable PCB Assembly: Why It Matters

Many failures in wearable devices occur after soldering. That’s why functional testing, X-ray inspection, and environmental simulations (humidity, thermal cycling) are crucial.

Top EMS for smart health monitors perform:

-

Burn-in testing

-

Flex cycle tests for bendable PCBs

-

Leakage testing for medical-grade enclosures

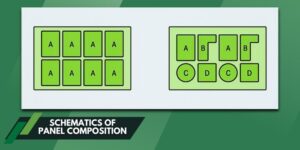

Why Panelization Is the Game-Changer for Wearable PCB Manufacturing

Panelization allows you to manufacture multiple boards in one go, speeding up production and reducing costs. It’s essential for:

-

Ultra-small PCBs that are hard to handle individually

-

Automated SMT assembly and AOI testing

-

Reducing flex damage during reflow

Wearable EMS providers increasingly offer free panelization design, ensuring your layout supports both prototyping and mass production. This reflects the broader 2025 trend toward modular, scalable design.

According to IEEE research on elastic wearable systems, the demand for flexible, hybrid PCBs in health monitoring wearables is driving EMS providers to adopt elastic circuits and stretchable substrates.

Small Batch PCB Manufacturing for Startups: No MOQ Doesn’t Mean Low Quality

Hardware startups need to iterate fast. But traditional EMS factories demand high volume orders.

Modern EMS partners offer:

-

1-50 unit runs

-

Fast turnaround in 3–7 days

-

DFM feedback to help refine designs

-

BOM matching with alternate component sourcing

Zero-MOQ doesn’t mean low service quality. Instead, it allows for low-risk testing, especially for new markets like AI-powered wearable modules.

EMS for Smartwatch and Fitness Tracker Projects: Technical Considerations

These wearables require:

-

Compact multilayer HDI PCBs

-

Waterproof connector integration

-

BLE modules and battery management systems

-

Thin enclosures with flexible circuit interconnects

EMS providers must excel at tight component placement, high-frequency RF testing, and co-molding or sealing for final enclosures.

Modern fitness wearables increasingly integrate haptic feedback and EMS-based microcontrollers for motion assistance and biometric analysis, as seen in IEEE studies on EMS-based wearable devices.

FAQs

1. What makes an EMS provider ideal for flexible PCBs in wearable devices?

Flexible PCBs are essential in wearables due to their compact, bendable form. The ideal EMS provider for wearable devices offers flexible circuit assembly, precision SMT on flex materials, and mechanical stress testing. A lack of flex expertise often leads to solder joint failure or delamination—choose an EMS with proven wearable sensor integration capabilities and flex handling workflows.

2. Why should startups choose EMS with no MOQ and fast prototyping services?

Startups often need rapid iterations before scaling. Choosing an EMS for wearable electronics with no MOQ allows for low-risk, small-batch PCB testing. EMS partners offering fast prototyping EMS services accelerate go-to-market timelines while providing design-for-manufacturing (DFM) insights early. Avoid EMS vendors that delay small orders or skip quality checks on prototypes.

3. How do turnkey PCB assembly services reduce product launch risk for wearables?

Turnkey PCB assembly for wearable devices means one partner handles sourcing, assembly, testing, and logistics—minimizing miscommunication and delays. For health wearables or AIoT devices, this centralized workflow reduces errors during post-soldering services and ensures compliance with certifications like RoHS or ISO13485. It’s ideal for reducing launch risk and speeding certification approval.

4. What sets China EMS companies apart in wearable PCB manufacturing?

A China EMS company for wearable PCB projects typically offers cost-effective, high-quality services with rapid turnaround. Many support small batch PCB manufacturing for startups with advanced capabilities in flexible boards, HDI layouts, and sensor integration. Look for providers offering one-stop services, from DFM review to testing, with global logistics support.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Best EMS for Medical Wearable Electronics: Certifications & Testing Requirements

For health wearables (ECG patches, glucose sensors, etc.), your EMS must offer:

-

ISO13485 and RoHS compliance

-

Traceable lot control

-

Biocompatibility material handling

-

100% functional testing

Companies like Sanmina, Plexus, and Zollner are equipped for these requirements. But newer firms with agile setups also offer compliant services at a fraction of the cost.

Your EMS Partner Should Offer More Than Assembly — They Should Offer Insight

In 2025, a good EMS is not just a vendor—they’re your design advisor, supply chain consultant, and QA partner.

Our service offers:

-

One-stop turnkey assembly

-

Free panelization recommendations

-

No MOQ orders

-

Rapid DFM feedback within 24 hours

-

Dedicated support from SMT through to packaging

Ready to take the next step?

Upload your BOM file now and receive complimentary panelization guidance + a full DFM review tailored to your wearable project. Not all EMS providers are equal—especially in fast-turn wearable projects. Before choosing, consider doing an SMT line audit using this detailed SMT factory audit checklist to ensure equipment, process flow, and testing standards meet expectations.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

Top 15 EMS Companies Supporting UK & European Electronics Brands [2025 Ranking]

Discover the top EMS companies in Europe and the UK for 2025. Compare capabilities, compliance,

Top 10 SMT Factory Audit Checks to Ensure Reliable PCB Assembly Quality in China

Discover 10 essential SMT factory audit checks to ensure PCB assembly quality in China—boost reliability,

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!