BGA Assembly

High-Quality BGA Assembly Services Since 2017

- Single & Double-Sided BGA Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

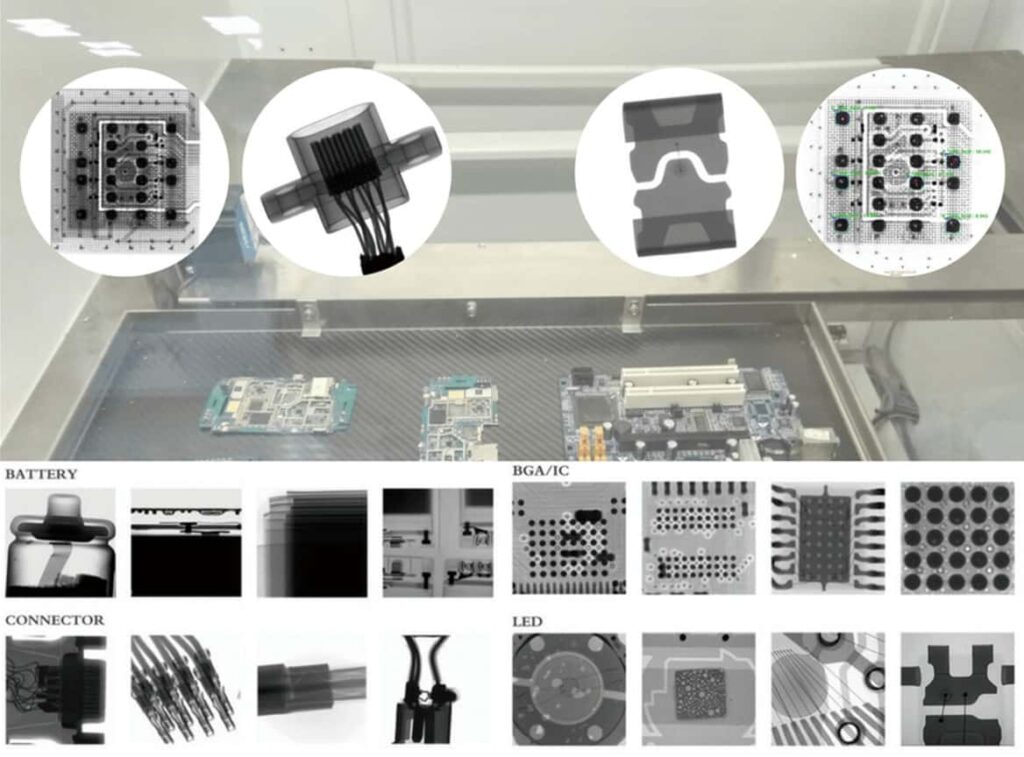

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 components, BGA, micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

BGA Assembly

BGA assembly plays a vital role in modern electronics, especially for high-performance devices. Many engineers and decision-makers still find the process complex when sourcing BGA assembly services for PCB manufacturing needs. This guide will break down BGA technology, its advantages, and its applications, helping you make informed decisions when sourcing PCBA services for your next project.

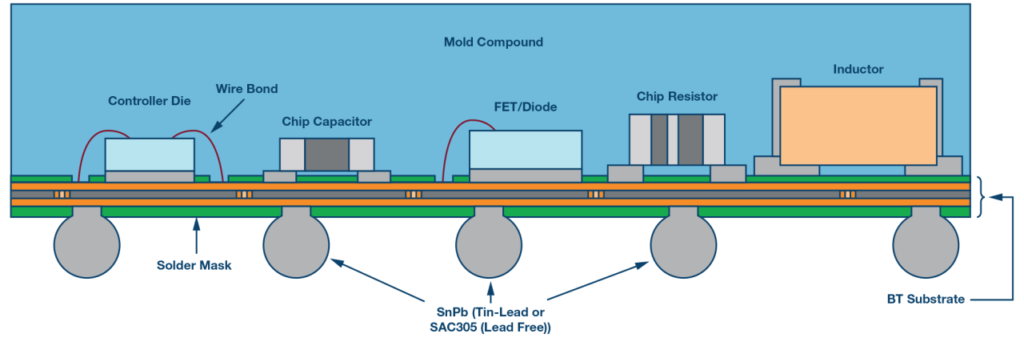

BGA Assembly is one of the most efficient methods for placing ball grid arrays onto a PCB. Using automatic reflow soldering, BGA components feature arrays of solder balls that form electrical connections with the PCB, providing high pin density and enhanced thermal performance. This technology is widely used in devices like microprocessors, offering more interconnections than traditional surface-mount packages.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is BGA Assembly?

BGA assembly is the process of mounting ball grid arrays (BGAs) onto a PCB using the solder reflow technique. Unlike traditional components, BGAs are surface-mount devices (SMDs) that use an array of solder balls to establish electrical connections with the PCB. These solder balls replace the pins found in conventional component packages, allowing for higher pin density and better performance.

BGAs are used for complex integrated circuits like microprocessors, where the need for high-density connections is essential. This technology also allows for more efficient use of space and offers improved electrical performance, making it a key choice for modern electronics.

What is BGA Technology?

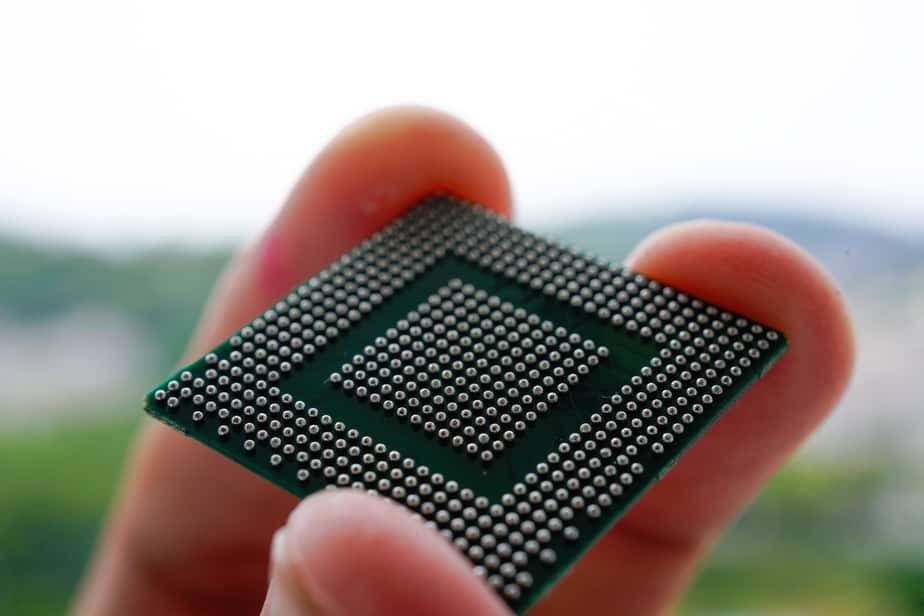

A Ball Grid Array (BGA) is a type of surface-mount packaging used for integrated circuits. BGA packages are primarily used to mount devices such as microprocessors, memory chips, and power components. Instead of having pins like traditional integrated circuits, BGAs feature a grid of tiny solder balls arranged on the underside of the component. These balls are melted during the soldering process, establishing a reliable electrical connection with the PCB.

The BGA package is favored because it can provide more interconnection pins than dual in-line or flat packages, allowing for better electrical performance, improved heat dissipation, and greater component density.

What is the Difference Between PCB and BGA?

While both BGA and PCB are integral to electronic design, they serve different purposes:

- A Printed Circuit Board (PCB) is the physical platform used to mount and interconnect electronic components, providing pathways for electrical signals.

- A Ball Grid Array (BGA) is a type of packaging for integrated circuits. It uses solder balls for connections rather than pins.

BGA is primarily used to mount high-density components on the PCB, providing superior performance compared to traditional packaging methods.

How Does BGA Work?

BGA soldering is a method of connecting integrated circuits to a circuit board. Instead of using pins like traditional packages, BGAs rely on small solder balls arranged in a grid on the underside of the component. These solder balls are melted during the soldering process, securely bonding the BGA to the PCB.

This method enables high pin density, allowing for more connections in a smaller area. Additionally, BGA assemblies have better thermal performance, making them ideal for high-performance applications such as microprocessors, where heat dissipation is crucial.

Advantages of BGA Technology

BGA technology provides several advantages over traditional PCB mounting techniques:

- Higher Pin Density: BGA allows for more electrical connections in a smaller area. This is crucial for devices that require many connections, such as microprocessors and memory chips.

- Improved Thermal Management: The design of BGAs facilitates better heat dissipation. The array of solder balls helps to evenly distribute heat, reducing the risk of overheating in high-performance components.

- Increased Reliability: Since BGA packages don’t have leads that can be damaged, the solder balls offer a more durable connection. The solid solder joints also improve long-term reliability.

- Smaller Form Factor: BGA components are compact and help reduce the overall size of electronic devices. This is particularly beneficial in modern electronics, where space is often limited.

- Better Performance: BGAs provide lower inductance and resistance, enhancing signal integrity and reducing the risk of interference in high-frequency applications.

Types of BGA Packages

There are several types of BGA packages, each designed to suit different applications and manufacturing processes. The most common types include:

- 1.Plastic Ball Grid Array (PBGA):

The most common type of BGA, PBGA uses a plastic package that is suitable for most consumer electronic applications. It is cost-effective and offers a balance between performance and price. - 2.Ceramic Ball Grid Array (CBGA):

CBGA packages use a ceramic substrate, which offers better heat resistance and is ideal for high-performance or high-reliability applications. These are often used in aerospace and military electronics.

- 3.Column Grid Array (CGA):

Unlike traditional BGAs, which use solder balls, CGAs use columns for connection. This variation is often used in situations where a more robust connection is needed, such as in industrial applications. - 4.Fine-pitch BGA (FPBGA):

FPBGA features a smaller pitch between solder balls, allowing for even more connections in a compact space. These are commonly used in high-performance processors and chips. - 5.MicroBGA:

A smaller version of BGA, MicroBGAs are designed for devices that require ultra-small packaging, like mobile phones and compact electronics. These packages provide a high number of connections in a tiny form factor.

Why Choose Unit Circuits As Your Partner?

When it comes to BGA assembly, Unit Circuits stands out as a trusted partner for businesses looking for reliable, high-quality services. Here’s why:

- Quality Assurance

Unit Circuits employs the latest SMT & TH technology to ensure the highest quality standards. From thorough inspection to rigorous testing, your project will meet industry standards. - Fast Turnaround

With our automated processes and experienced team, we offer quick assembly times, helping you reduce your time-to-market. - Competitive Pricing

We offer affordable pricing without compromising on quality. Our efficient process ensures cost savings for your project. - Comprehensive Services

From PCB design to final assembly, Unit Circuits offers end-to-end solutions for your SMT & THTneeds, making it easy to manage your project under one roof.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0