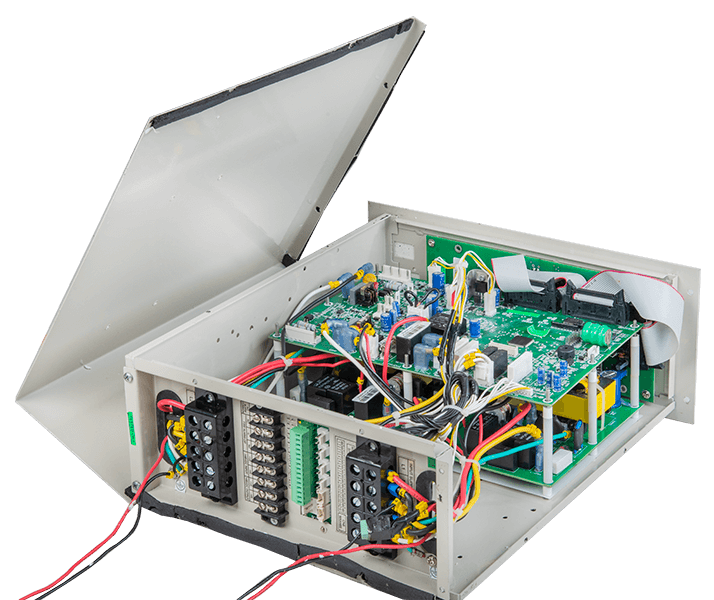

Box Building

Turnkey Box Build Assembly Services – From PCBA to Fully Integrated Systems

What Is Box Build Assembly and Why OEMs Choose It?

Complete box build services — PCBA, enclosure, cabling, and testing — for industrial & medical OEMs.

A box build assembly refers to the process of assembling printed circuit boards (PCBs), cables, and other electronic components into a fully enclosed chassis or enclosure. It is one of the later stages of electronics manufacturing, coming after PCB fabrication and component assembly.

Box build assembly combines mechanical, electrical, and aesthetic design to create a finished electronic product ready for use by the end customer. It requires skills in project management, supply chain coordination, quality control, mechanical integration, and testing. Companies that specialize in box builds are known as contract manufacturers or electronic manufacturing services (EMS).

Box Building Capability

Key Features of Our Box Build Assembly Services

Our turnkey box build services cover everything from custom enclosure assembly to component sourcing and rigorous testing. We help OEMs accelerate time to market by integrating all required hardware into a single, ready-to-ship solution.

👉 Whether you’re scaling production or starting from a prototype, Unit Circuits ensures reliability and flexibility at every stage.

Our Proven Box Build Process – From Design to Delivery

Our Box Build Process is designed to deliver reliability, speed, and quality at every step.

We follow a streamlined and proven approach to ensure that your product goes from concept to completion with minimal delays and maximum performance.

🛠️ Step 1: Design Consultation

We begin by understanding your project’s unique needs, ensuring that both mechanical and electronic specifications are aligned.

🧪 Step 2: Prototyping

A prototype is developed for your approval, giving you a tangible preview before full-scale production.

🏭 Step 3: Manufacturing

We scale up to production, maintaining strict quality control and efficient assembly workflows.

✅ Step 4: Testing

Every unit is rigorously tested for functionality, reliability, and compliance.

🚚 Step 5: Packaging & Delivery

Your finished units are securely packaged and shipped according to your timeline and logistics requirements.

Top 8 Reasons to Choose Unit Circuits for Box Build Assembly

All-in-One Solution:

Streamline your production with a single trusted partner for design, sourcing, assembly, and testing — reducing lead times and overhead costs.

Tailored to Your Needs:

Custom solutions for complex electronics or simple consumer products, ensuring a perfect fit for your specific application.

Certified Quality Control:

International standards, ISO9001 & UL certifications, and advanced testing like AOI and X-Ray ensure top-tier reliability and safety.

Cost Efficiency:

Benefit from bulk sourcing, optimized workflows, and lean production to lower manufacturing costs without sacrificing quality.

Faster Time to Market:

Accelerate your launch cycle with efficient workflows and rapid prototyping to meet tight market windows.

Innovation Leadership:

Backed by advanced R&D and years of experience, we deliver forward-thinking solutions that keep your product competitive.

Scalable & Flexible Production:

Flexible lines scale from prototypes to high-volume runs — ideal for startups and global OEMs

End-to-End Support:

From engineering advice to after-sales service, our experts ensure smooth communication and full project success.

What is a box build used for?

Box builds are used in a wide range of products, from consumer electronics like smartphones and laptops to industrial equipment and medical devices. Here are some uses and applications:

- Devices: Smartphones, tablets, smartwatches.

- Purpose: Protects and integrates electronics for daily use and sophisticated operations.

- Applications: Diagnostic equipment, patient monitoring systems.

- Purpose: Ensures reliable operation and protection from environmental conditions, critical for patient safety and accuracy.

- Uses: Communication equipment, network devices.

- Purpose: Facilitates the setup of robust and reliable communication infrastructures.

- Components: Control units, infotainment systems.

- Purpose: Provides housing for electronics that must endure the rigorous conditions of automotive environments.

- Devices: Routers, switches.

- Purpose: Ensures ease of installation and maintenance while protecting sensitive electronics.

- Field: Scientific research, quality control.

- Purpose: Houses instruments that require a controlled environment to maintain precision and accuracy.

- Applications: Avionics systems, communication devices.

- Purpose: Delivers robust and secure enclosures necessary for the high reliability demanded in these sectors.

- Devices: Power inverters, solar inverters, control systems.

- Purpose: Protects critical energy management systems, facilitating reliable energy distribution and management.

Customer Success Story

✔️Client Country:Australia

✔️Industry: Industrial Control Systems

✔️Challenge:Needed a customized enclosure with precise PCBA integration.

✔️Solution:Delivered turnkey box build assembly with custom shell, wiring, and QC.

✔️Result:Reduced assembly cost by 25% and shortened time-to-market by 2 weeks.

FAQs about Box Building

Box Building involves the comprehensive assembly of electronic systems including PCBs, wiring, and component integration into final product enclosures.

We implement a rigorous multi-stage testing protocol, ensuring every unit meets global standards for reliability and durability, reflecting our two decades of industry expertise.

Absolutely, we offer scalable solutions tailored to meet the specific needs of both small-scale projects and large-volume production.

Our optimized supply chain and efficient production processes reduce costs, providing you with high-quality manufacturing solutions at competitive prices.

We utilize advanced project management tools and techniques to coordinate all aspects of production, ensuring timely delivery and quality compliance.

Only the highest-quality materials and components sourced from trusted suppliers are used, ensuring the final product meets our rigorous standards.

Each product undergoes extensive functional and stress tests, including environmental simulations, to ensure top-tier performance and longevity.

With our fast quote and delivery system, we expedite processes without compromising quality, addressing urgent requirements efficiently.

Common Challenges in Box Build Assembly

Box build assembly, while crucial for the integration of electronic systems into their final products, presents several challenges that manufacturers must navigate to ensure quality and efficiency. Here are some of the key difficulties involved in box build assembly:

-

Complexity of Assembly:

- Box builds can range from simple enclosures with a few components to complex systems with multiple layered assemblies and intricate wiring. Managing these varying levels of complexity requires meticulous planning and precision.

-

Supply Chain Management:

- Effective supply chain management is crucial for timely and cost-effective production. Challenges include managing multiple suppliers, ensuring component quality, and coordinating delivery schedules to prevent production delays.

-

Customization Requirements:

- Each box build project may require customized components and configurations. Adapting production lines and processes to accommodate these custom specifications without compromising on efficiency or cost can be challenging.

-

Quality Control:

- Maintaining high quality throughout the assembly process is vital, especially for industries such as medical devices or aerospace where safety is paramount. Implementing rigorous testing and quality assurance protocols is necessary but can be resource-intensive.

-

Integration of Diverse Technologies:

- Modern electronic products often incorporate various technologies, including software, hardware, and mechanical components. Integrating these disparate elements seamlessly into a single functioning unit requires advanced engineering expertise.

-

Regulatory Compliance:

- Electronic products are subject to a range of regulations depending on their use and the markets they are sold in. Ensuring compliance with these regulations throughout the design and manufacturing process adds another layer of complexity.

-

Thermal Management:

- Effective heat dissipation is critical in electronic assemblies to prevent overheating and ensure product reliability. Designing enclosures that allow for adequate cooling while protecting sensitive components is a significant challenge.

-

Scalability Issues:

- Transitioning from prototype to mass production involves scaling up the assembly process without losing quality or increasing costs disproportionately. Achieving this scalability can be particularly challenging for complex assemblies.

-

After-Sales Support:

- The assembly process doesn’t end with the shipment of the product. Providing effective after-sales support, including maintenance, repairs, and upgrades, is crucial but can be complicated by the intricacies of the box build product.

-

Environmental Considerations:

- Environmental factors such as humidity, temperature, and exposure to chemicals can affect the performance of electronic enclosures. Designing assemblies that can withstand these conditions while maintaining functionality is challenging.

Addressing these challenges requires a combination of advanced engineering, effective project management, and stringent quality control processes. Success in box build assembly often hinges on the ability to adapt and innovate in response to these complexities.

At Unit Circuits, we specialize in overcoming these challenges with efficient, tailored solutions. Let our experts help you plan your next box build project. Request your free quote today.

Let’s Build Your Next Project Together

With years of experience in turnkey PCBA and box build services, Unit Circuits helps OEMs streamline production, reduce costs, and ensure product quality.

From custom enclosures to complex integrations, our engineers are ready to support your next project with precision and care.

Reach out now to get your free, no-obligation quote.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0