Quick Leads

What Are the Most Common Challenges in IC Programming?

The Most Common Challenges in IC Programming

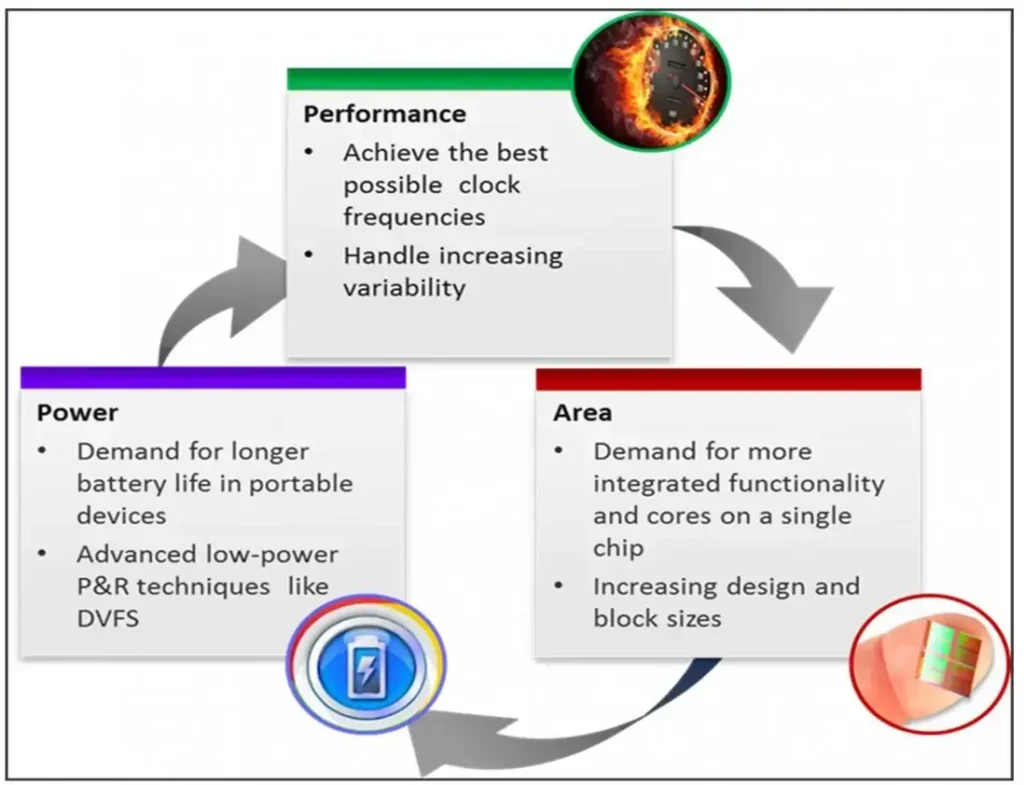

1. Balancing Power, Area, and Performance

Challenges in Mobile & Embedded Systems

- Smaller devices need to use power and space efficiently.

- High-performance systems can increase power consumption and generate more heat.

Techniques for Power Optimization

- Dynamic Voltage Scaling: Adjusts voltage levels based on workload.

- Clock Gating: Turns off unused parts of the circuit to save power.

Tools for Performance Balancing

- Cadence Design Systems: Optimizes IC designs for power and area.

- Synopsys Design Compiler:Helps you balance performance without sacrificing power efficiency.

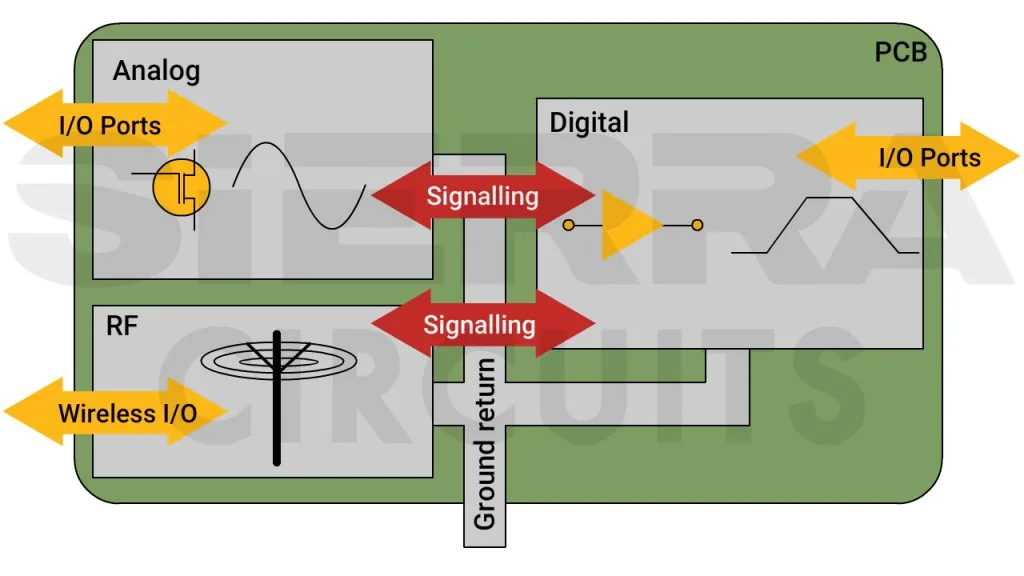

2. Mixed-Signal IC Designs: Signal Interference and Synchronization

Techniques for Synchronization

- Phase-Locked Loops (PLLs): Synchronizes analog and digital signals.

- Signal Integrity Tools: Analyzes and optimizes signals to reduce interference.

Key Tools to Reduce Interference

- TDRs and VNAs: Identify and mitigate signal integrity issues.

- Power Distribution Networks (PDNs): Reduce noise between analog and digital parts.

3. Cybersecurity in ICs: Preventing Unauthorized Access

Key Cybersecurity Techniques

- End-to-End Encryption: Secures data transmission between devices.

- Firewalls and Intrusion Detection Systems (IDS): Protects against unauthorized access.

- Multi-Factor Authentication: Adds an additional layer of security.

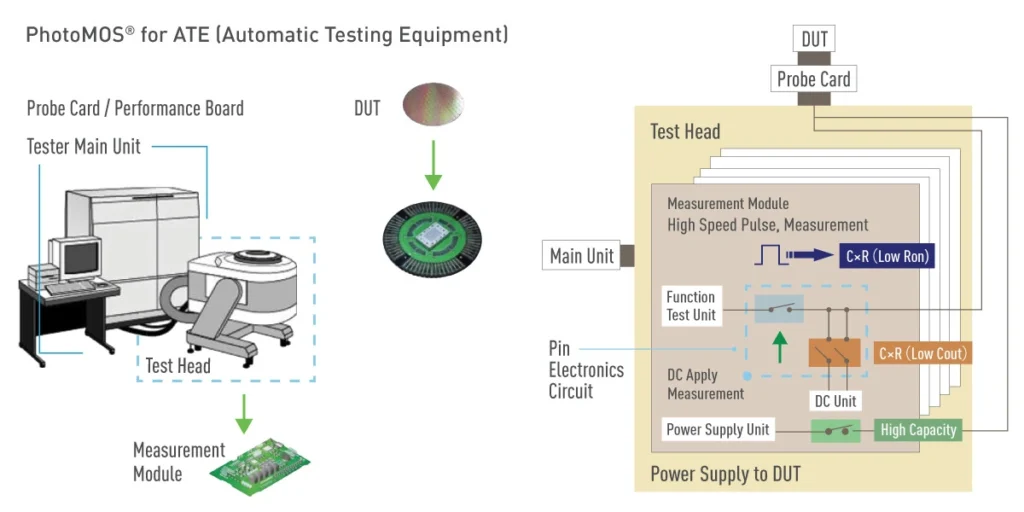

4. Testing IC Chips: Managing Complexity in High-Frequency Designs

Testing Methods and Tools

- Automated Test Equipment (ATE): Simulates different operating conditions.

- In-Circuit Emulators (ICEs): Provides real-time feedback during testing.

Continuous Testing

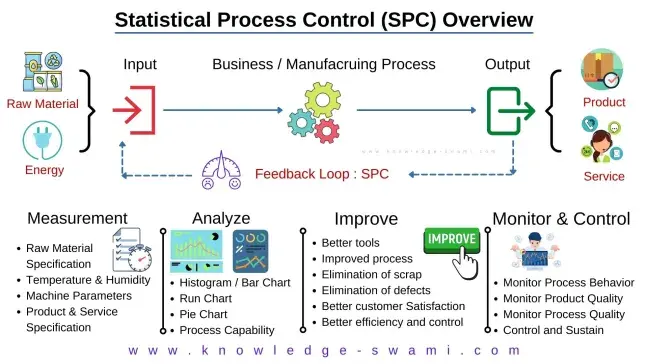

5. Manufacturing Variability and Process Control

Solutions to Minimize Variability

- Design-for-Manufacturing (DFM): Uses simulations to detect potential defects early.

- Statistical Process Control (SPC): Monitors production processes to maintain consistency.

6. Challenges in Mobile & Embedded Systems

For more information, visit below:

Frequently Asked Questions (FAQs)

For high-frequency IC testing, you use ATE (Automated Test Equipment) and ICEs (In-Circuit Emulators) to simulate different conditions. You need to test and get feedback all the time to make sure that your chip works well.

Thermal management is a big deal in high-performance ICs. You use thermal simulation tools, heat sinks, and advanced packaging techniques to get rid of heat and keep your chip from getting too hot.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Key Takeaways:

- Balancing power, area, and performance is critical in IC design, especially for mobile and embedded systems.

- Mixed-signal ICs need good synchronization and signal integrity management to reduce interference.

- Cybersecurity is important for keeping ICS safe from unauthorized access and making sure they run safely.

- Testing ICs requires special equipment and continuous feedback to make sure you have high-quality, working designs.

- You can minimize manufacturing variability with advanced DFM and process control techniques to make sure you have consistent production.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!