Quick Leads

6 Essential Elements to Consider When Purchasing PCBA for Your Startup

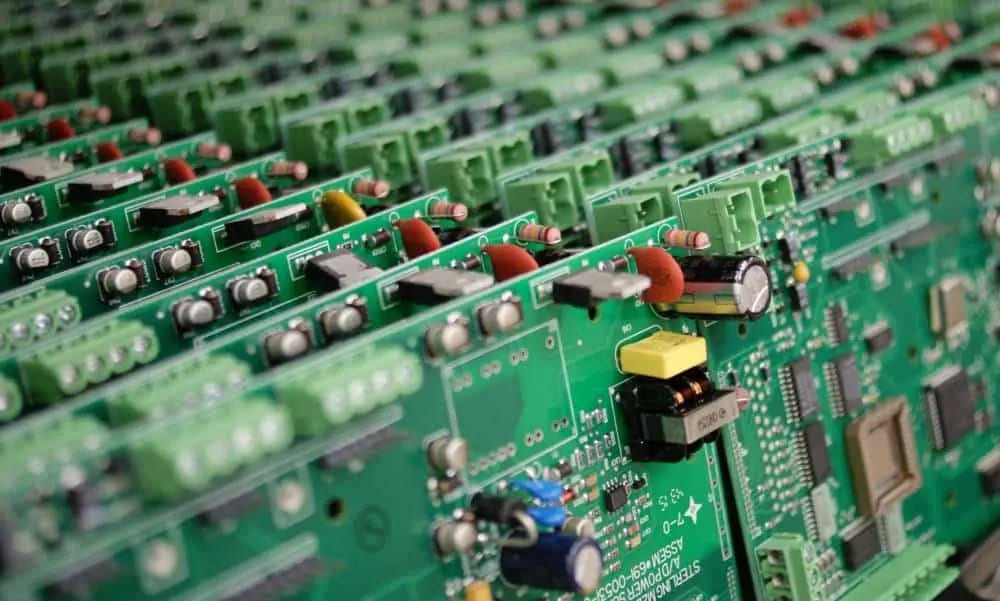

When sourcing Printed Circuit Board Assemblies (PCBA), especially for small startup businesses, choosing the right supplier is critical. With numerous factors influencing the cost, quality, and reliability of your assembly, it can be overwhelming to make the best decision.

In this article, we’ll walk through six essential elements you must consider to ensure you select the best PCBA supplier for your needs.

When purchasing a Printed Circuit Board Assembly (PCBA), six key factors should be considered: cost, quality, lead time, manufacturer capabilities, flexibility with sampling, and the supplier’s reputation. Cost impacts the overall project budget, while quality control ensures reliability. Lead time is essential, especially for startups needing fast prototyping. Manufacturer capabilities matter for small-batch production. Flexibility in sampling is key when prototyping, and finally, a reliable supplier ensures the long-term success of your project.

Why Is Cost an Important Factor When Purchasing PCBA?

Cost is one of the most critical factors when purchasing PCBA. Whether you’re a large corporation or a small startup, staying within budget while maintaining product quality is crucial. PCBA costs can vary significantly based on several factors, including design complexity, material choices, and order volume. Understanding these factors can help you avoid overpaying and ensure you get the best value for your investment.

For small startups, finding a cost-effective PCBA supplier is essential, but it’s important that quality is never compromised. As many PCB manufacturers have high minimum order quantities (MOQ), it can be difficult to find an affordable solution for low-volume production. Therefore, you must choose a supplier that offers competitive pricing without sacrificing quality, ensuring that your product performs reliably in the market.

What Are the 7 Types of PCB Testing Methods?

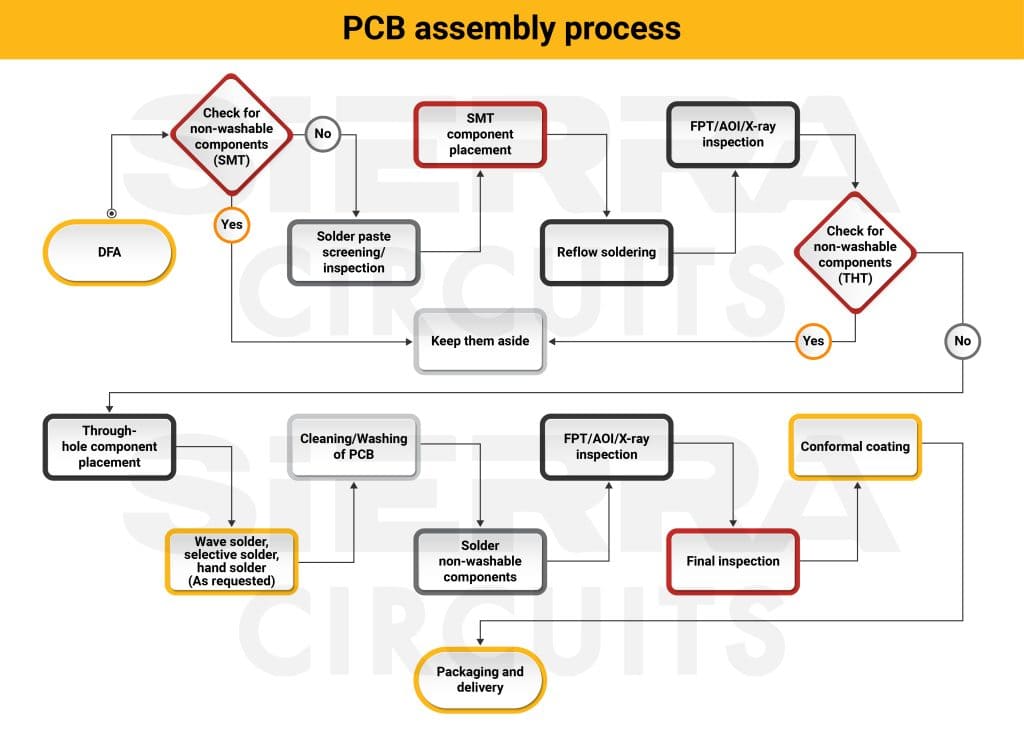

Ensuring the quality of your PCBA is vital to the success of your product. Different testing methods are used to verify the integrity and functionality of your PCBA. Some of the most common methods include:

- In-Circuit Testing (ICT): Checks for electrical faults by testing each component in the circuit.

- Flying Probe Testing: A cost-effective method for smaller batches using probes to test the PCB.

- Automated Optical Inspection (AOI): Uses cameras to inspect the soldering quality and component placement.

- X-ray Inspection: Essential for checking hidden solder joints, especially in high-density PCBs.

- Burn-In Testing: Applies electrical current to the PCBA to ensure durability and reliability under stress.

- Functional Testing: Verifies that the circuit performs its intended functions.

- Solderability Testing: Ensures components will successfully solder onto the PCB.

A good PCBA manufacturer should offer multiple testing options to ensure the final product is reliable, functional, and up to industry standards.

For a more detailed look at PCB testing, check out this guide on testing methods.

How Do I Choose the Right PCB Manufacturer for My Startup?

Choosing the right PCB manufacturer is crucial for a smooth production process. When selecting a supplier, consider these key elements:

- Production Capacity: Does the manufacturer have the ability to scale production based on your needs? For small startups, you may need a supplier that can accommodate both small prototype runs and larger mass productions as your business grows.

- Technical Expertise: A PCB supplier with in-depth knowledge of PCB design and assembly can help you avoid common mistakes, provide design feedback, and optimize your product for better performance.

- Reputation and Reviews: Check the manufacturer’s track record with past customers. Look for reviews and testimonials that can provide insight into the quality of their service and products.

- Certifications: Make sure the supplier holds the necessary certifications (such as ISO 9001) to guarantee that their processes meet international quality standards.

By evaluating these elements, you’ll ensure that you choose a reliable, capable, and cost-effective PCB supplier for your product.

What Is PCBA and Why It’s Crucial for Your Business Success?

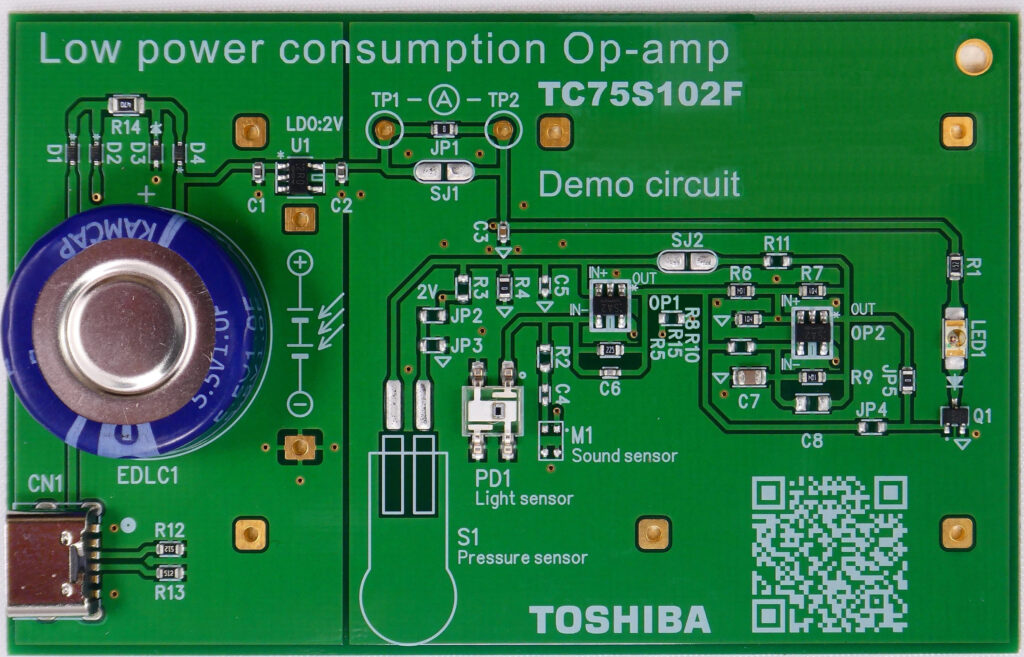

PCBA, or Printed Circuit Board Assembly, refers to the final product after components are soldered onto a PCB. It’s a crucial step in turning your design into a functioning product. The quality of the PCBA directly affects the performance, durability, and overall success of your product in the market.

For small startups, selecting a manufacturer that produces high-quality PCBAs is especially important. Poor-quality PCBA can lead to functionality issues, which could be disastrous for your brand reputation and project timelines. Therefore, always prioritize quality control and ensure that the manufacturer uses the latest technologies and testing methods.

How Can I Ensure My PCBA Supplier is Reliable?

Reliability is one of the most important qualities you should look for in a PCBA supplier. As a small startup, you’re likely under tight deadlines and limited resources. Any delays or quality issues could cause significant setbacks.

To assess a supplier’s reliability:

- Evaluate Their Track Record: Look for manufacturers who have a proven track record in delivering on time and meeting quality standards.

- Customer Testimonials: Reach out to past clients or read reviews to gauge the supplier’s reputation.

- Certifications and Standards Compliance: Ensure that the supplier adheres to international quality standards (ISO, IPC, etc.).

- Communication: A reliable supplier should offer clear and responsive communication throughout the entire process, from design to delivery.

By selecting a reliable PCB supplier, you can ensure a smoother production process and avoid unexpected delays.

What Are the Key Criteria for Selecting PCB Materials?

Selecting the right materials for your PCBA is essential for ensuring performance, longevity, and manufacturability. Some key factors to consider include:

- Dielectric Constant (Dk): Affects signal speed and impedance.

- Dissipation Factor (Df): Impacts signal loss, especially in high-speed circuits.

- Thermal Conductivity (TC): Helps manage heat dissipation, which is crucial for performance and reliability.

- Coefficient of Thermal Expansion (CTE): Ensures the materials expand and contract at similar rates during temperature changes to prevent damage.

By working closely with your PCBA supplier, you can ensure that the materials selected are optimized for your design’s requirements.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary: How to Select the Right PCBA Supplier for Your Startup

Selecting the right PCBA manufacturer involves balancing cost, quality, lead time, and flexibility to meet your specific needs. By considering these six key elements—cost, quality control, lead time, manufacturer capabilities, sampling flexibility, and supplier reliability—you can avoid common pitfalls and ensure that your product is built on a solid foundation. Don’t rush the decision-making process; a reliable and competent PCBA supplier will be a key partner in your business’s long-term success.

Next Steps for Choosing Your PCBA Supplier

Are you ready to find the right PCBA supplier for your startup? Don’t hesitate to contact us for more information or download our

guide on PCB supplier selection to make a more informed decision. You can also sign up for our newsletter to receive expert tips on optimizing your PCB design and assembly process!

guide on PCB supplier selection to make a more informed decision. You can also sign up for our newsletter to receive expert tips on optimizing your PCB design and assembly process!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!