Double-Sided PCB Assembly

High-Quality Double-Sided PCB Assembly Services Since 2017

- Double-Sided PCB Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 Components, BGA, Micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

Double-Sided PCB Assembly

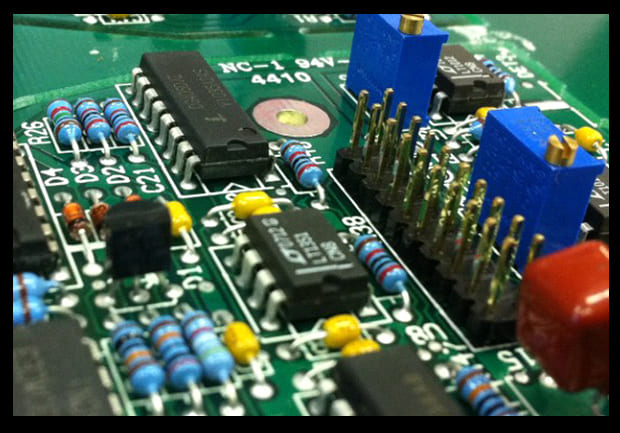

Double-Sided PCB Assembly refers to the process of mounting components on both sides of a printed circuit board (PCB). Unlike single-sided PCBs, where components are placed only on one side, double-sided PCBs allow for more efficient use of space and higher component density, making them ideal for more complex and advanced electronics. Whether you’re a beginner, a professional, or a business owner looking to outsource PCB assembly services, this guide will walk you through everything you need to know about Double-Sided PCB Assembly.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is Double-Sided PCB Assembly?

Double-Sided PCB Assembly is a type of PCB assembly where components are mounted on both sides of the board. The conductive pathways (traces) are laid out on both sides of the PCB, enabling a higher component density and more efficient use of space. Double-sided PCBs are widely used in devices that require more complex circuits and components, such as smartphones, industrial machinery, and automotive systems.

Why is Double-Sided PCB Assembly important?

This method allows for more complex and dense circuit designs, which makes it ideal for advanced electronic products that require both high performance and small form factors. It also helps reduce the overall size of the product by utilizing both sides of the PCB, which is especially important in industries where compact designs are crucial.

What is the Double-Sided PCB assembly process?

Double-Sided PCB assembly involves mounting components on both sides of the PCB, using advanced techniques such as Surface Mount Technology (SMT) and Through-Hole Technology (THT). The assembly process includes placing components, soldering them in place, and performing extensive quality control to ensure functionality.

The Benefits of Double-Sided PCB Assembly

Double-Sided PCB Assembly offers several advantages, particularly for more complex and space-efficient designs. Some key benefits include:

- 1.Higher Component Density

By utilizing both sides of the PCB, more components can be placed in the same space, enabling the design of more compact and powerful devices. - 2.Better Performance

Double-sided PCBs are often used in applications where high-frequency signals and complex circuits are required. The ability to use both sides of the board helps optimize signal routing and improves overall performance.

- 3.Space Efficiency

With components placed on both sides, double-sided PCBs can accommodate larger or more complex circuits without increasing the board size, which is crucial for space-constrained applications like wearable electronics and mobile devices. - 4.Cost-Effective for Complex Designs

While double-sided PCBs are more complex to manufacture than single-sided boards, they offer a cost-effective solution for applications requiring high-density components and advanced features, which would otherwise require multiple single-sided boards.

The Main Challenges in Assembling Double-Sided PCBs

Double-Sided PCB Assembly, while offering many advantages, also comes with some challenges. These include:

- Alignment and Placement Issues

The process of placing components on both sides of the PCB can lead to alignment and placement difficulties. Ensuring that components are positioned correctly on both sides is crucial to avoid misalignments that can result in malfunctioning circuits. - Soldering Challenges

Soldering on both sides of the board is more complicated than single-sided assembly. Components on the second side may need to be flipped and reflow soldered, leading to potential issues such as cold joints, solder bridges, and insufficient solder. - Thermal Management

Double-sided PCBs can present challenges in thermal management. The presence of components on both sides of the board can make it difficult to dissipate heat effectively, requiring additional heat management solutions like thermal vias or heat sinks. - Increased Manufacturing Complexity

Double-Sided PCB Assembly is more complex than single-sided assembly. The process requires careful planning, precise component placement, and more advanced manufacturing equipment. This complexity can lead to longer production times and higher costs. - Component Accessibility for Rework

With components placed on both sides of the board, rework and repair become more difficult. It can be challenging to access components on the back side of the PCB, requiring special techniques or equipment for repair.

By using advanced technologies and maintaining strict quality control processes, these challenges can be mitigated, ensuring a reliable and high-quality assembly.

What is the Double-Sided setup?

The Double-Sided setup involves placing components on both sides of the PCB, enabling higher-density designs. This allows for more efficient use of space, particularly in applications requiring compact, high-performance circuits.

The Key Processes in Double-Sided PCB Assembly

Double-Sided PCB Assembly involves several key steps to ensure a reliable and functional end product. These include:

- Board Preparation

The PCB is cleaned and prepared, removing contaminants, oils, or residues that could affect soldering or component placement. This ensures the board is ready for efficient assembly.

- 2.Component Placement

Components are placed on both sides of the board. For Surface Mount Technology (SMT), automated pick-and-place machines are used, while Through-Hole components may require manual placement or wave soldering. - 3.Soldering

After placement, the board undergoes a soldering process. The first side is typically soldered using reflow soldering. After flipping the board, the second side is soldered, either using reflow soldering or wave soldering, depending on the components. - 4.Inspection and Testing

After assembly, each board is thoroughly inspected to identify defects such as poor solder joints, misaligned components, or trace damage. The boards are also electrically tested to ensure that they function properly.

Why Choose Unit Circuits As Your Partner?

When it comes to Double-Sided PCB Assembly, Unit Circuits is your trusted partner for high-quality, reliable services. Here’s why:

- Expertise in Double-Sided Assembly

With years of experience in Double-Sided PCB Assembly, we have the expertise in both SMT and THT to meet your specific requirements, no matter how complex your designs may be. - Quality Assurance

We implement strict quality control measures to ensure your PCBs meet the highest standards. From design to testing, our focus is on delivering a flawless product every time. - Fast Turnaround and Cost-Effectiveness

Our efficient manufacturing processes allow us to offer quick turnaround times for Double-Sided PCBs, all while maintaining competitive pricing. - Comprehensive Support

From consultation to the final product, we offer full support at every step of the assembly process, ensuring your project is completed successfully and to your satisfaction.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0