Flex PCB Assembly

High-Quality Flex PCB Assembly Services Since 2017

- Single & Double-Sided SMT/TH Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 components, BGA, micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

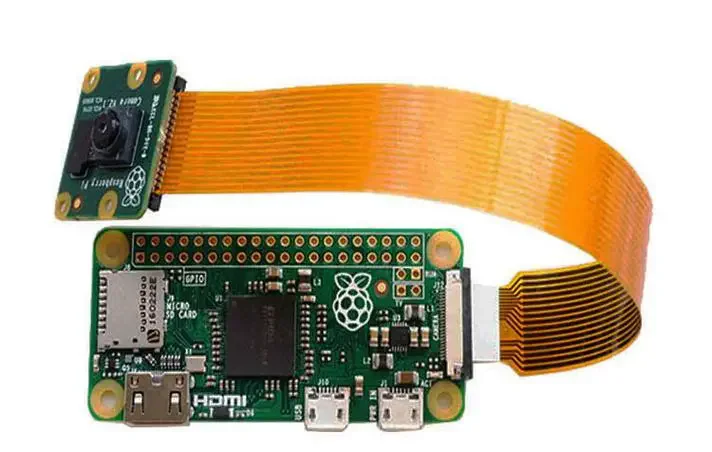

Flex PCB Assembly

Flexible PCB Assembly is a cutting-edge technology that is transforming the way electronic devices are designed and manufactured. In this guide, we’ll explore what flexible PCBs are, their advantages, and how the assembly process works. Understanding flexible PCB assembly can help streamline your decisions when sourcing high-quality PCB assembly services for your next project.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

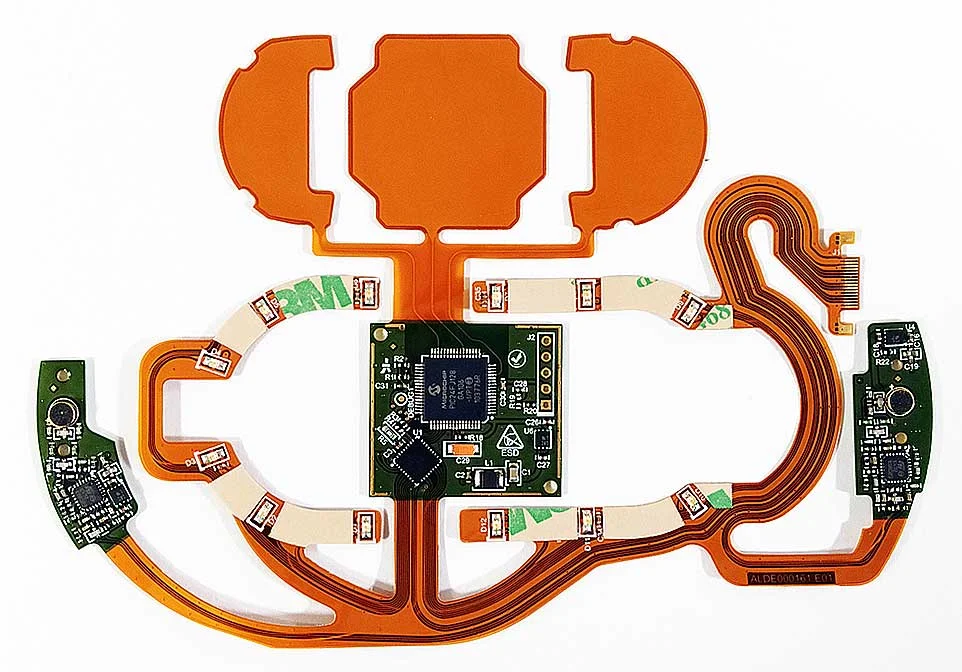

Flexible PCBs (Printed Circuit Boards) are made from flexible materials that allow them to bend, twist, and fit into compact or irregular shapes. Unlike rigid PCBs, flexible PCBs are built using materials such as polyimide or polyester films, making them ideal for applications where flexibility is needed. These boards can be used in various configurations, including single-sided, double-sided, and multi-layer designs.

What is Flexible PCB and Why is It Important?

Flexible PCBs are printed circuit boards made from materials that can bend and flex. They consist of several layers, including a flexible substrate, copper traces, and a protective solder mask. Here’s a breakdown of the key components:

- Flexible Substrate Layer: The core material, typically made of polyimide or polyester, which allows the PCB to bend and conform to different shapes.

- Copper Layer: Forms the electrical connections and traces.

- Solder Mask Layer: Protects the copper traces from environmental damage.

- Silk Screen Layer: Adds markings and labels for component placement and assembly.

Flexible PCB Assembly Cost: What You Need to Know

The cost of flexible PCB assembly can vary based on several factors:

- Design Complexity: More intricate designs, such as multi-layer boards or those with fine traces, can increase assembly costs.

- Volume: Larger orders usually reduce the per-unit cost as economies of scale come into play.

- Materials Used: The cost of flexible substrates, such as polyimide, can impact the overall price.

- Manufacturing Location: Labor costs and materials availability in different regions can affect pricing.

Typically, flexible PCB assembly costs range from $10 to $100 per unit, depending on the specifications.

Flexible PCB vs Rigid PCB: Which is Right for You?

When choosing between flexible and rigid PCBs, it’s important to consider the needs of your application. Here’s a quick comparison of the two: Flexible PCBs are ideal for applications requiring adaptability and compact designs, while rigid PCBs are best suited for stable, high-volume environments.

| Feature | Flexible PCB | Rigid PCB |

|---|---|---|

| Flexibility | Can bend, twist, and flex | Rigid and inflexible |

| Applications | Wearable tech, aerospace, medical devices | Automotive, industrial, consumer electronics |

| Cost | Higher due to specialized materials | Lower for mass production |

Popular Applications of Flexible PCB Assembly

Flexible PCBs are used in a wide range of industries, especially where compactness and flexibility are critical. Here are some common applications:

- Wearable Electronics: Smartwatches, fitness trackers, and other portable devices rely on flexible PCBs to conform to the contours of the body.

- Medical Devices: Flexible PCBs are used in medical equipment such as diagnostic tools, implantable devices, and wearable health monitors.

- Consumer Electronics: Smartphones, tablets, and other compact electronic devices benefit from the space-saving and lightweight characteristics of flexible PCBs.

- Automotive: Used in advanced driver-assistance systems (ADAS), infotainment, and power control units, flexible PCBs enable innovative automotive designs.

Why Choose Unit Circuits As Your Partner?

When it comes to SMT PCB assembly, Unit Circuits stands out as a trusted partner for businesses looking for reliable, high-quality services. Here’s why:

- Quality Assurance

Unit Circuits employs the latest SMT technology to ensure the highest quality standards. From thorough inspection to rigorous testing, your project will meet industry standards. - Fast Turnaround

With our automated processes and experienced team, we offer quick assembly times, helping you reduce your time-to-market. - Competitive Pricing

We offer affordable pricing without compromising on quality. Our efficient process ensures cost savings for your project. - Comprehensive Services

From PCB design to final assembly, Unit Circuits offers end-to-end solutions for your SMT needs, making it easy to manage your project under one roof.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0