Quick Leads

FR4 vs. Aluminum PCBs: How to Choose the Right One for Optimal Performance and Cost-Efficiency

Choosing the Right PCB Material: FR4 vs. Aluminum PCBs

When designing electronic circuits, selecting the right PCB material is essential for both performance and cost-efficiency. FR4 is the most common choice for most designs due to its affordability and versatility. However, for applications requiring superior heat dissipation, Aluminum PCBs offer distinct advantages. In this guide, we’ll compare FR4 and Aluminum PCBs, helping you decide which material suits your project’s thermal requirements and budget constraints.

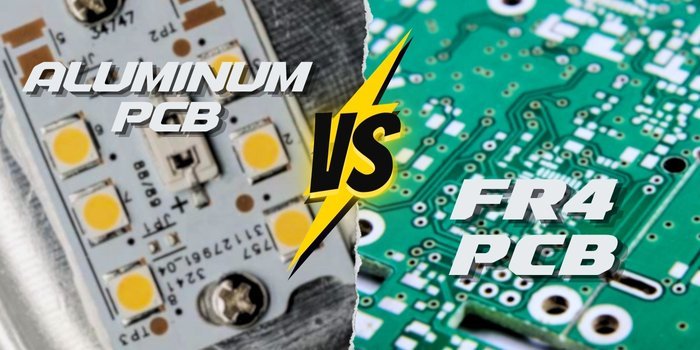

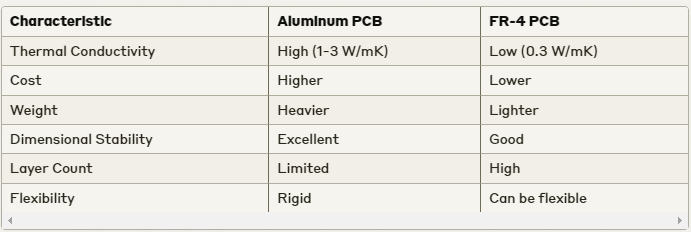

FR4 vs Aluminum PCBs: Key Differences Explained

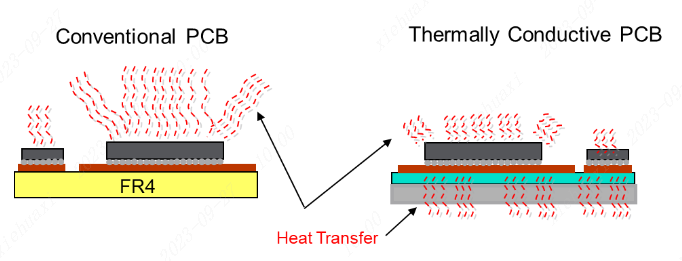

FR4 and Aluminum PCBs are both popular choices in the PCB industry, but they serve different purposes. FR4 is a fiberglass-reinforced epoxy laminate, offering flexibility, low cost, and ease of manufacturing. It’s ideal for standard electronics and low-to-moderate power applications. Aluminum PCBs have a metal core that helps dissipate heat. This makes them the best choice for high-power applications like LEDs or power electronics.

-

FR4 PCBs: Affordable, versatile, and flexible in design.

-

Aluminum PCBs: Enhanced thermal dissipation for heat-sensitive applications.

When to Choose Aluminum PCBs for High-Power Applications

If your design involves high power or significant heat generation, Aluminum PCBs are the superior choice. Their metal core allows heat to dissipate quickly, preventing overheating and damage to sensitive components. This feature is especially critical in applications where high temperatures can severely impact performance or longevity.

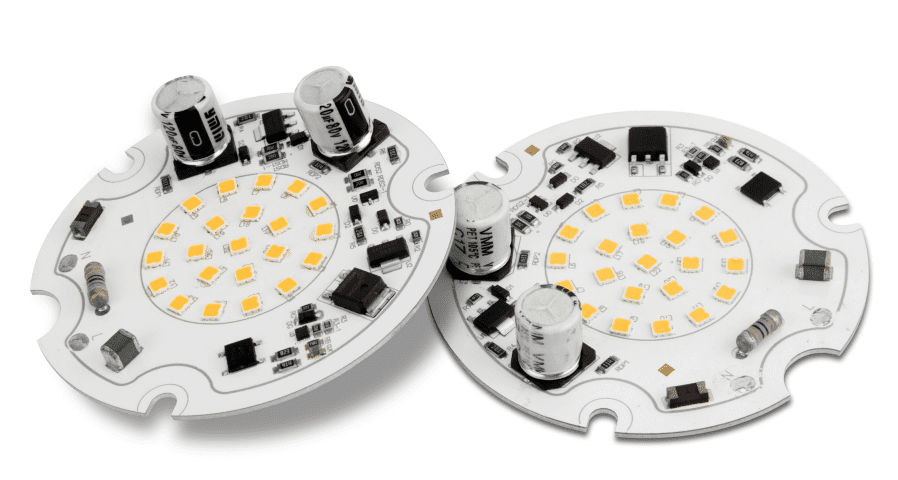

For example, Aluminum PCBs are commonly used in LED lighting, where high heat levels can drastically reduce the performance and lifespan of the components. These PCBs ensure that the components remain cool, thus improving their efficiency and durability.

Aluminum boards are good for power stuff like amplifiers, car lights, and industrial stuff. You need to get rid of heat to make sure your stuff works.

The Cost-Effectiveness of FR4 PCBs

One of the primary reasons FR4 PCBs are so widely used is their cost-effectiveness. If you’re working with a budget and don’t require advanced thermal management, FR4 is the ideal choice. It’s easy to manufacture, widely available, and cost-efficient, making it suitable for general-purpose electronics such as consumer devices, automotive electronics, and more.

Advantages of FR4 PCBs:

-

Cost-Effective: Less expensive than Aluminum PCBs, ideal for mass production or budget-sensitive projects.

-

Versatility: Can be manufactured in single, double, or multi-layer formats, offering great flexibility.

-

Widely Available: Easy to source, making it perfect for general-purpose electronics.

FR4 is cheap. That’s why you find it in things like phones, tablets, and appliances. You don’t need to worry about heat as much.

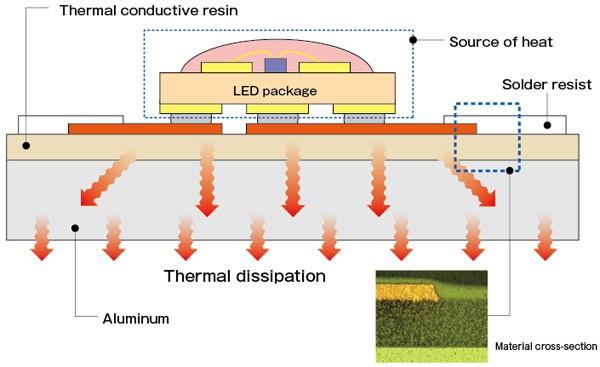

How Aluminum PCBs Improve Thermal Performance

The primary benefit of Aluminum PCBs is their ability to manage heat more effectively than FR4. Aluminum PCBs are 600 times better at getting rid of heat than FR4. This is important for high-power stuff like LEDs and power electronics.

The metal core in Aluminum PCBs acts as a heat sink, efficiently transferring excess heat away from sensitive components. This results in more reliable performance, especially in power-hungry devices. As electronics get more powerful, heat management is a big deal.

Unlike FR4, Aluminum PCBs spread heat all over the board. This keeps hot spots from forming. Hot spots can make your board die early or just stop working.

Which PCB Material is Right for Your Design Needs?

Choosing the right PCB material comes down to understanding your project’s unique needs. Here are some key factors to consider:

-

Thermal Requirements: If your design generates significant heat, Aluminum PCBs are your best option. They are ideal for power electronics, LEDs, and high-performance devices.

-

Cost Constraints: If you’re working with a limited budget, FR4 is a good choice. It works for most things.

-

Power Requirements: For low to moderate power devices, FR4 works well. For high-power applications like LED arrays, Aluminum PCBs are superior.

Cost vs. Performance: The FR4 vs Aluminum Tradeoff

When comparing FR4 and Aluminum PCBs, there’s always a tradeoff between cost and performance. FR4 is cheaper but lacks the heat dissipation capabilities of Aluminum PCBs. On the other hand, Aluminum PCBs are more expensive, but they keep your board from getting hot. This makes your stuff last longer and work better.

If you need a board that gets rid of heat and works well, you should spend the extra money on an aluminum board. It will save you money in the long run because you won’t have to fix it or replace it as often.

Thermal Management: A Crucial Factor in PCB Selection

Thermal management is a critical factor when deciding between FR4 and Aluminum PCBs. If your design involves high heat generation, an Aluminum PCB is likely your best choice. The metal core spreads heat all over the board. This keeps your stuff cool and makes it last longer.

In industries like cars, medical stuff, and things like that, you need your stuff to work all the time. Aluminum boards make sure your stuff works when it’s hot or cold.

Key Benefits of Aluminum PCBs for Thermal Management:

Excellent heat dissipation properties, especially for LED and power applications.

Increased device lifespan by preventing overheating.

Greater performance stability in high-power electronics.

Applications of Aluminum PCBs in Different Industries

Aluminum boards are getting more popular because they get rid of heat better. Below are some key applications where Aluminum PCBs play a critical role:

-

LED Lighting: Aluminum boards are good for LEDs. They keep your LEDs from getting too hot. If your LEDs get too hot, they die early and don’t work as well.

-

Power Electronics: Aluminum boards are good for power supplies, inverters, and stuff like that. You need to get rid of heat to make sure your stuff works.

-

Automotive Electronics: Cars have a lot of electronics in them. They have LED lights, power stuff, and batteries. Aluminum boards keep all that stuff from getting too hot.

-

Medical Devices: Medical stuff needs to work all the time. Aluminum boards keep your stuff from getting too hot. That’s why you need them.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Whether you’re designing a high-power device or a budget-friendly consumer gadget, the right PCB material can make all the difference. FR4 offers affordability and versatility for general-purpose applications, while Aluminum PCBs provide superior thermal management for heat-sensitive, high-power devices. Contact us today to discuss your specific project needs, and we’ll help you choose the perfect solution!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!