Quick Leads

Fiducials, useful?

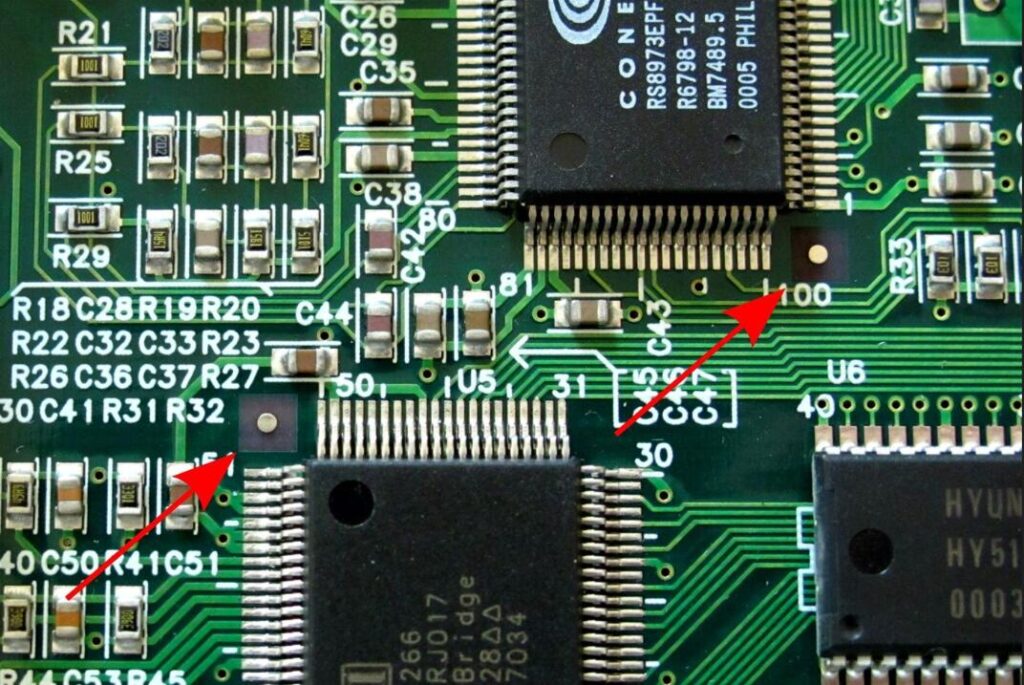

In the world of electronics, the precision of component placement on printed circuit boards (PCBs) can make or break the functionality of a device. Companies searching for reliable PCB assembly suppliers often prioritize accuracy to avoid costly errors. Yet, one critical element that ensures this precision is often overlooked: fiducials.

Fiducials are small, precise markers on a PCB, typically made of exposed copper, that serve as reference points for automated machines. They are essential for ensuring accurate component placement, particularly in high-density assemblies, by guiding pick-and-place machines and aligning stencils during the assembly process.

When your products depend on flawless execution, understanding and implementing fiducials can be the difference between success and costly rework.

What are Fiducials in PCB Assembly?

Fiducials are reference marks that are placed on a PCB during its design and manufacturing stages. These markers are usually circular or square and are surrounded by a clearance area of exposed copper. Their primary function is to act as visual guides for automated machines, such as pick-and-place machines, which are responsible for placing electronic components onto the PCB with high precision.

Without fiducials, these machines would struggle to correctly align and position components, leading to potential misplacements that could compromise the entire circuit’s performance. This is especially critical in designs with small components and tight spacing, where even minor misalignments can cause significant issues.

Why Are Fiducials Important?

Fiducials play a crucial role in modern PCB assembly by ensuring that every component is placed precisely where it needs to be. This precision is vital for several reasons:

- Enhanced Accuracy: Fiducials provide a consistent reference point for machines, enabling them to make fine adjustments and ensure components are aligned correctly.

- Reduced Errors: By guiding the assembly process, fiducials help minimize the risk of component misplacement, reducing the likelihood of errors that could lead to defective products.

- Improved Efficiency: Automated machines can operate more efficiently with fiducials in place, as they can quickly and accurately locate reference points, speeding up the assembly process.

How to Implement Fiducials in Your PCB Design

Placement: Fiducials should be placed on opposite corners of the PCB to provide a stable reference frame. This helps the machines to calculate angles and distances accurately.

Clearance: Ensure there is a sufficient clearance area around the fiducial to prevent interference from other components or traces. The recommended clearance is typically 1 mm around the fiducial.

Size: The size of the fiducial should be appropriate for the design. A common size is 1 mm in diameter, but this can vary based on the specific requirements of your design and the capabilities of your assembly machines.

Types: Consider using global fiducials (placed on the board’s perimeter) and local fiducials (placed near specific components) to ensure the highest level of precision.

What are the Components of a PCB Assembly?

In addition to fiducials, a PCB assembly involves several critical components:

- Active Components: These include transistors, diodes, and integrated circuits, which are essential for the PCB’s functionality.

- Passive Components: Resistors, capacitors, and inductors fall under this category, providing necessary electrical resistance, capacitance, and inductance in the circuit.

- Connectors: These are used to join the PCB with other boards or external devices, allowing for the transmission of electrical signals.

- Solder Mask: This protective layer helps to prevent solder bridges and protects the copper traces from oxidation.

- Silkscreen: The silkscreen layer contains labels and markings, such as component designators and logos, which aid in assembly and troubleshooting.

Common Mistakes to Avoid with Fiducials

Even though fiducials are straightforward to implement, some common mistakes can compromise their effectiveness:

- Incorrect Placement: Placing fiducials too close to the edges of the board or near large components can lead to alignment issues.

- Inadequate Clearance: Not providing enough clearance around the fiducial can result in interference during the assembly process.

- Using Non-Standard Sizes: Deviating from standard fiducial sizes can confuse automated machines and lead to errors.

By avoiding these mistakes, you can ensure that your PCB assembly process is as accurate and efficient as possible.

Frequently Asked Questions

Fiducials are small pads placed on a PCB to aid pick-and-place machines during component placement. They are frequently added to the rails of a PCB array to ensure accurate assembly.

Fiducials are most commonly used for aligning components during PCB assembly. They ensure that the components are placed precisely where they need to be on the board.

The number of fiducials required depends on the complexity of the PCB. Typically, at least two global fiducials are used, but more may be necessary for complex designs.

A common fiducial size is 1 mm in diameter, but this can vary depending on the design and machine requirements.

Conclusion

Choosing the right PCB assembly supplier involves more than just cost and lead time considerations. Ensuring that they have a deep understanding of fiducials and their importance in the assembly process can save your company time, money, and headaches down the line. By implementing fiducials correctly, you enhance the precision, reliability, and overall quality of your electronic products.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!