Quick Leads

Gold Finger PCBs: Types, Benefits, and Applications

What Is a Gold Finger in PCB?

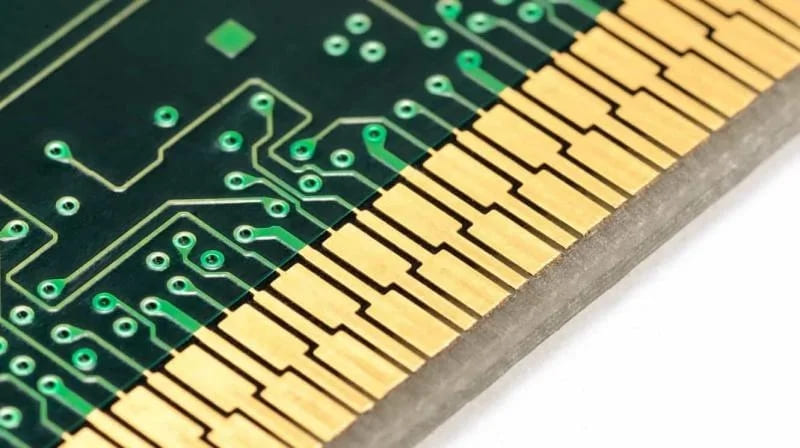

A Gold Finger PCB is a type of printed circuit board (PCB) with gold-plated edge connectors, commonly known as “gold fingers.” These connectors provide reliable electrical connections between the PCB and other electronic systems, ensuring high-speed and stable data transfer. Gold-plated PCB connectors are chosen for their superior conductivity and resistance to wear, making them ideal for long-lasting, high-performance applications.

Why Is Gold Used in PCBs?

Gold is widely used in Gold Finger PCBs due to its remarkable conductivity, corrosion resistance, and reliability. As a noble metal, gold does not tarnish or corrode, ensuring long-lasting electrical connections in high-performance PCBs. This is particularly crucial in demanding industries like aerospace, medical devices, and consumer electronics, where stability and durability are vital. The excellent conductivity of gold minimizes signal degradation and reduces resistance, enhancing the overall efficiency of the PCB.

What Electronics Use Gold Finger Connectors?

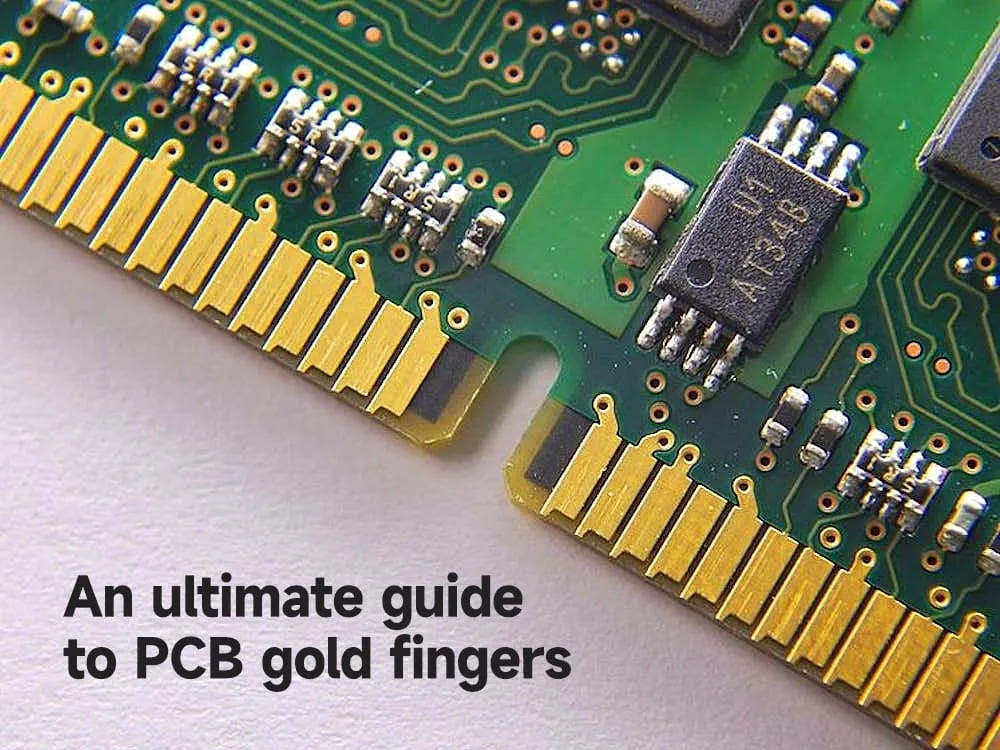

Gold fingers are widely utilized in various electronic applications, particularly in devices that require reliable, high-performance connections. Common examples include:

- Graphics Cards: These cards use gold-plated PCB connectors to ensure high-speed, stable communication between the card and motherboard.

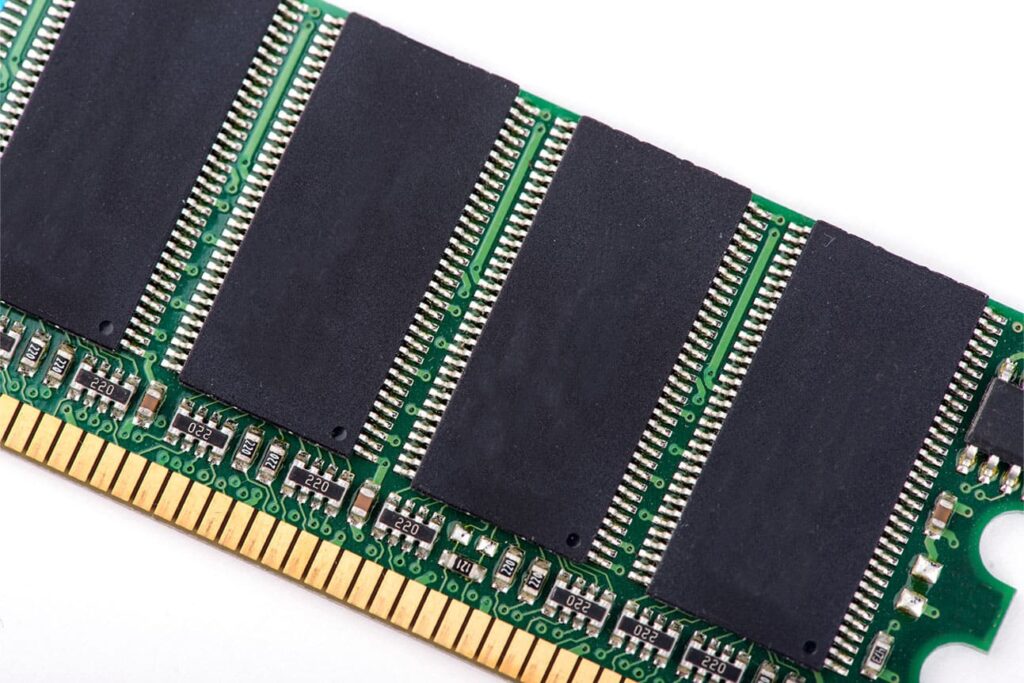

- Memory Modules (RAM): Gold finger connectors on memory modules ensure fast, consistent data transfer between the memory and motherboard, enhancing system performance.

- Expansion Cards: Gold Finger PCBs in devices like network interface cards (NICs) and sound cards facilitate robust communication across various systems.

- High-Performance Servers: Gold-plated PCB connectors ensure stable and efficient connections in data centers and enterprise-level server systems.

Millennium Circuits Limited: Guide to Gold Finger PCB Design, you can see details here.

How to Balance Cost and Design When Using Gold Finger PCBs?

Balancing cost and design is crucial when using Gold Finger PCBs. Gold plating on PCB connectors offers excellent durability and conductivity, but it can be expensive. The thickness of the gold plating plays a significant role in determining the overall cost. Thicker plating offers better durability and performance but increases the cost. Designers often need to decide based on the application whether a thinner gold plating will suffice for less demanding environments, or if a thicker gold finger plating is necessary for critical, high-traffic applications like aerospace or medical devices.

How Do Gold Fingers in PCBs Improve Performance?

Gold finger PCBs enhance performance in several ways:

- Superior Durability: Gold’s corrosion resistance and wear resistance make gold-plated PCB connectors highly durable and suitable for high-contact applications.

- Improved Electrical Conductivity: Gold finger connectors offer minimal resistance, allowing efficient signal transfer even at high speeds.

- Extended Lifespan: Since gold does not oxidize, Gold Finger PCBs tend to last longer, maintaining reliable performance for extended periods.

- Corrosion Resistance: The gold plating provides protection against environmental factors, making Gold Finger PCBs suitable for industries where exposure to harsh conditions is common.

- Seamless Compatibility: These connectors ensure secure connections across multiple PCBs, making them ideal for modular systems such as expansion cards and memory modules.

All About Gold Fingers on PCBs from Rush PCB, you can see this guide too.

What Are the Different Types of Gold Finger PCBs?

Several types of Gold Finger PCBs cater to different performance needs:

- Standard Gold Finger PCBs: The most commonly used gold-plated PCB connectors, providing a balance between cost and reliability for consumer-grade electronics.

- Thick Gold Finger PCBs: Used in high-end applications like military electronics and aerospace, where durability and longevity are crucial.

- Gold Finger Edge Connectors: Designed to connect multiple PCBs, ensuring high-performance and stable connections across modular systems.

- Micro Gold Finger PCBs: These are compact gold finger connectors used in devices with limited space, such as smartphones and wearables.

- Flash Gold Plating: Cost-effective gold finger PCB connectors often used for consumer-grade electronics, where the connectors are not subject to frequent contact.

- Hard Gold Finger PCBs: Hard gold plating is used for applications that require frequent insertions and removals, such as industrial machinery or consumer electronics.

Gold Finger Applications in Specialized Industries

Gold finger connectors play a vital role in industries that demand high reliability, durability, and performance. Some specialized applications include:

- Aerospace: In aerospace, Gold Finger PCBs are critical for ensuring reliable data transmission in flight control systems, avionics, and satellite communication systems. Due to the harsh environment—extreme temperatures, radiation, and vibrations—gold’s corrosion resistance and durability make it essential for aerospace applications.

- Medical Devices: Gold finger PCB connectors are widely used in medical equipment, including diagnostic tools and life-saving devices like pacemakers and defibrillators. The longevity and stability provided by gold are essential for maintaining functionality over time in mission-critical medical systems.

- Automotive Electronics: Modern vehicles depend on reliable electronic systems for safety and performance. Gold finger connectors in automotive electronics, such as advanced driver-assistance systems (ADAS) and infotainment systems, ensure robust connections that can withstand the harsh automotive environment.

Industry Standards for Gold Finger PCBs

Industry standards and certifications are essential for ensuring the quality and reliability of Gold Finger PCBs. Adhering to these standards helps manufacturers produce high-performance connectors that meet stringent requirements. Key industry standards include:

- IPC Standards: IPC (Institute for Printed Circuits) standards, such as IPC-2221A, set guidelines for PCB design, ensuring that gold finger PCBs meet performance requirements. IPC-6012, which addresses high-performance PCB manufacturing, is particularly relevant for industries like aerospace and medical devices.

- ISO Certifications: Manufacturers of Gold Finger PCBs should have ISO certifications such as ISO 9001 for quality management and ISO 13485 for medical devices. These certifications ensure that the manufacturer maintains high-quality standards and adheres to best practices in production.

Frequently Asked Questions

A gold finger in PCB refers to the gold-plated edge connectors that allow a printed circuit board to establish reliable electrical connections. These gold-plated connectors ensure stable data transfer between PCBs and electronic systems.

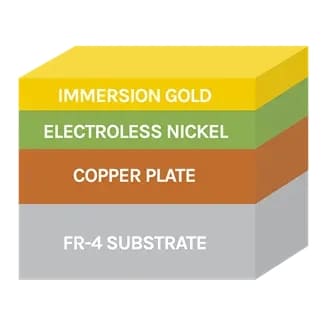

The thickness of the gold plating typically ranges from 0.003 to 0.005 mils, depending on the application. Thicker gold plating offers higher durability and is often used in mission-critical applications.

The amount of gold used in Gold Finger PCBs is usually measured in microinches, with plating thickness ranging from 0.003 to 0.005 mils. The amount varies depending on the application’s durability requirements.

Gold finger connectors are common in electronics such as graphics cards, memory modules (RAM), and network interface cards (NICs). These connectors are used for high-speed and reliable data transfer in various computing devices.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion: Balancing Design and Cost in Gold Finger PCBs

When designing and manufacturing Gold Finger PCBs, it’s essential to strike a balance between cost, design, and performance. Thicker gold plating offers enhanced durability and conductivity but comes at a higher cost, while thinner plating is more affordable but may sacrifice longevity. Read this article to know how to design your PCBs.

By carefully evaluating the specific needs of the application, manufacturers can select the appropriate gold-plated PCB connectors that offer the best balance between cost-effectiveness and long-term performance. Contact us freely for fulfill you next project.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!