Quick Leads

How Conformal Coating Enhances PCB Durability in Harsh Environments?

Introduction

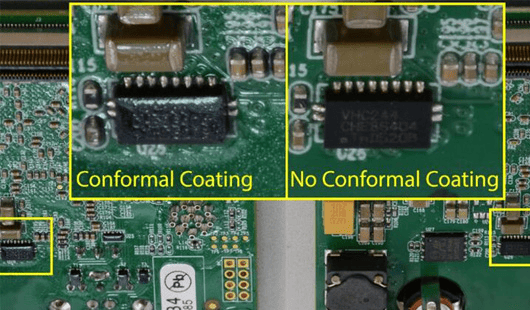

Did you know that conformal coating can extend the lifespan of PCBs by up to 10 years in extreme conditions? When designing PCBs for use in harsh environments, durability is key. Conformal coating acts as a protective layer, shielding PCBs from the damaging effects of moisture, dust, chemicals, and extreme temperatures. This article will explore how conformal coatings improve PCB protection and enhance their performance in challenging conditions.

In addition to conformal coating, proper PCB assembly and PCB manufacturing are crucial for ensuring the durability and functionality of your PCBs in harsh environments. Learn more about PCB assembly here and PCB manufacturing here.

What Are the Drawbacks of Conformal Coating for PCB Durability?

While conformal coatings provide remarkable protection, they do have some potential drawbacks. The thickness of the coating can affect the tolerances of components on the PCB, which may impact overall performance. Additionally, the coating process can sometimes mask manufacturing defects, making inspections and repairs more difficult.

Despite these challenges, careful selection of the appropriate coating material and application method can significantly reduce these risks, ensuring optimal performance and protection.

If you’re unsure which coating is best for your PCB, check out this guide on selecting the best coating for electronic components to help make an informed decision.

What Is the Lifespan of Conformal Coating?

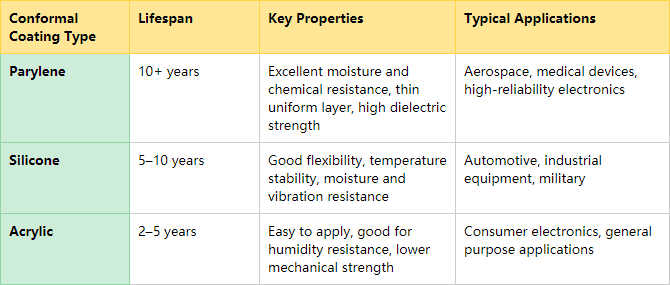

The lifespan of conformal coatings varies based on the material and the environment in which it is applied. For instance, Parylene coatings are known for their exceptional durability, with Parylene N lasting up to 2,200 years at room temperature without exposure to light. Other materials, such as silicone and acrylic coatings, also offer long-lasting protection, though their durability may vary depending on the exposure conditions.

For high-reliability applications, especially in space and aerospace, Parylene is often the preferred choice due to its ultra-thin and uniform coverage. However, for less demanding applications, silicone or acrylic may be more cost-effective while still providing reliable protection.

If you’re interested in understanding more about Parylene and how it’s used in aerospace, take a look at this in-depth article on Parylene coatings.

Potential Hazards of Conformal Coating

While conformal coating offers excellent protection, the application process can involve some safety hazards. Chemicals like isocyanates, epoxy resins, and solvents used in certain coatings can release volatile organic compounds (VOCs) that are harmful if inhaled. Proper ventilation and personal protective equipment (PPE) are essential to ensure safety during application.

Despite these risks, conformal coatings offer significant benefits when proper safety protocols are followed. Choosing safer coating materials like water-based or low-VOC options can further mitigate these concerns.

For more on eco-friendly coating options, here’s a link to learn about low-VOC coatings, which can be safer for both workers and the environment.

Which Conformal Coating Best Protects PCBs from Moisture and Dust in Harsh Environments?

Silicone conformal coating is particularly effective in protecting PCBs from moisture, dust, and other environmental contaminants. It provides a flexible, durable barrier that resists corrosion and performs well in high-humidity environments. Acrylic coatings also offer excellent protection against moisture but may not be as effective in extreme temperatures as silicone.

For environments exposed to chemicals or abrasion, epoxy coatings provide superior protection due to their robust and durable finish. However, they tend to be more rigid and may crack under stress, making them less suitable for applications requiring flexibility.

Best Conformal Coating for PCB

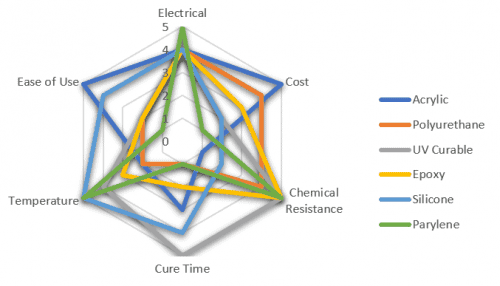

Selecting the best conformal coating depends on the application and environmental conditions. Here’s a breakdown of popular coating materials for PCBs:

- Acrylic Conformal Coatings: Ideal for general-purpose applications, offering moisture and mild chemical resistance.

- Silicone Conformal Coatings: Best for high-temperature environments and applications requiring flexibility.

- Epoxy Conformal Coatings: Known for strong resistance to abrasion and chemicals, perfect for harsh industrial settings.

- Parylene Conformal Coatings: Exceptional for high-reliability applications, such as in aerospace, medical devices, and space applications.

- Polyurethane Conformal Coatings: Versatile and durable, providing good protection against chemicals, moisture, and physical stress.

Each type of conformal coating has unique properties that make it suitable for different environmental challenges. Silicone coatings excel in high-temperature environments, while Parylene is the choice for space and military applications due to its ultra-thin and uniform application.

If you’re considering the various PCB materials available for your project, this guide to selecting the best materials might help.

Conformal Coating vs Potting

When comparing conformal coating vs potting, it’s important to understand their key differences. Potting involves encapsulating the entire PCB in a solid material, like epoxy, which offers excellent protection but lacks the flexibility of conformal coatings. Conformal coatings, on the other hand, provide flexibility, which is critical for applications where the PCB needs to bend or move without cracking.

Conformal Coating vs Solder Mask

Conformal coating and solder masks both protect PCBs, but they serve different purposes. Solder masks prevent unwanted soldering during assembly, whereas conformal coatings provide environmental protection after assembly. Conformal coatings offer superior protection against moisture, dust, and chemicals, making them the better choice for harsh conditions.

Conformal Coating vs Nail Polish

A common misconception is that nail polish can be used as a substitute for conformal coatings. While nail polish may offer temporary protection, it lacks the durability, flexibility, and resistance required for high-reliability electronics. Conformal coatings are specifically designed for PCBs, providing long-term protection against environmental stressors.

Conformal Coating Process

The process of applying conformal coating to PCBs involves several key steps:

- Preparation: Cleaning the PCB to remove contaminants and ensure proper adhesion.

- Coating Application: Applying the coating using methods such as spraying, dipping, or brushing.

- Curing: Curing the coating at room temperature or using heat, depending on the type of material.

- Inspection: Ensuring the coating is uniform and free from defects.

For high-volume production, conformal coating equipment, such as spray booths or coating pens, can streamline the process, ensuring consistent and reliable protection for every PCB.

The application of conformal coating follows a careful preparation process. It’s essential to start with high-quality PCB manufacturing to ensure a smooth coating. Learn more about the PCB manufacturing process here.

Frequently Asked Questions

Conformal coating vs potting differs mainly in their application. Conformal coating is a thin, flexible layer applied to PCB boards for protection against moisture, dust, and chemicals, while potting involves encasing the entire PCB in a solid material like epoxy, providing a more rigid and robust form of protection. Conformal coating is ideal for applications requiring flexibility, while potting is best for applications needing mechanical strength.

No, nail polish should not be used as a substitute for conformal coating on PCBs. While it might offer temporary protection, it lacks the durability, flexibility, and resistance required for reliable long-term performance. Conformal coatings for PCBs are specifically designed to protect against environmental stressors, making them far more reliable for electronics than nail polish.

For high-temperature environments, silicone conformal coatings are ideal due to their heat resistance and flexibility. Silicone coatings provide excellent protection in extreme heat. For high-reliability applications like aerospace, Parylene conformal coatings are often preferred for their ultra-thin and uniform protection.

Yes, certain conformal coatings such as silicone and acrylic can help make PCBs resistant to moisture and humidity. While they may not make the PCB completely waterproof, they do provide a high level of protection against moisture and minor liquid exposure, preventing corrosion and other damage in harsh environments.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

Summary

Conformal coating plays a critical role in ensuring the durability of PCBs in harsh environments. By selecting the appropriate coating material, engineers can protect PCBs from environmental stressors such as moisture, dust, and extreme temperatures, ultimately extending their lifespan. Always keep in mind that proper application methods and safety protocols are key to maximizing the benefits of conformal coatings.

For more information on how conformal coatings can protect your PCBs in harsh environments, contact us today for a personalized quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!