Quick Leads

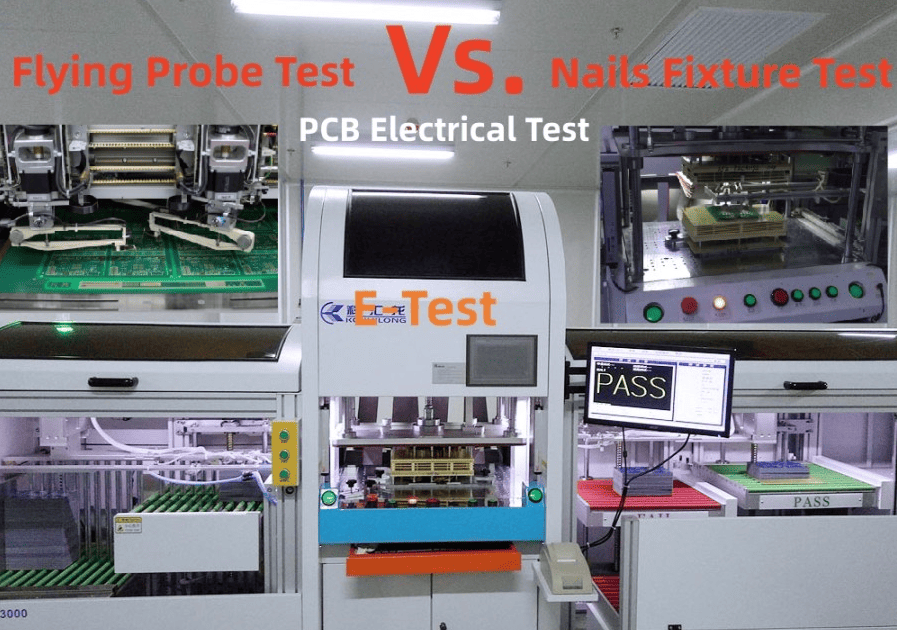

How Does the E-Test Fixture Differ from Flying Probe Testing?

Selecting the Right PCB Testing Method for Quality and Cost Efficiency

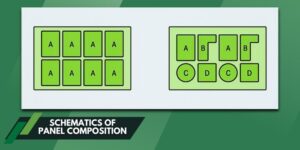

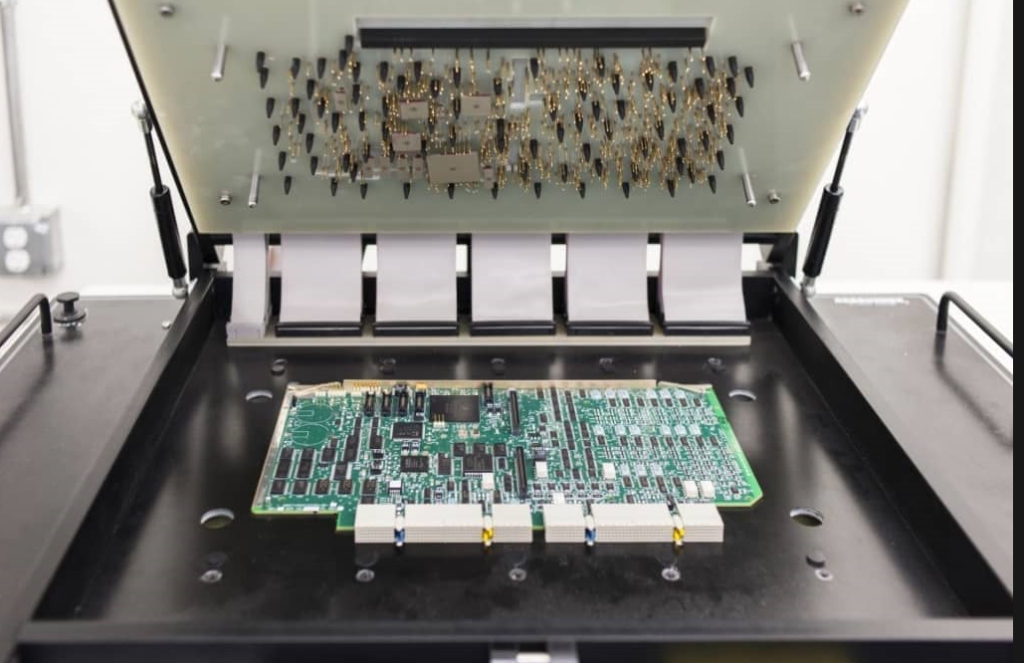

What is an E-Test Fixture for High-Volume PCB Testing?

Advantages:

- High throughput: It’s fast and good for making a lot of PCBs.

- Consistent accuracy: Ensures reliable testing for densely populated boards.

- Scalability: Once set up, the fixture can test thousands of units quickly and efficiently.

Limitations:

- Higher initial cost: It costs a lot to set up the fixture, especially if you have a complicated design.

- Limited flexibility: It’s hard to change the fixture, so it’s not good for changing your design.

Use Cases:

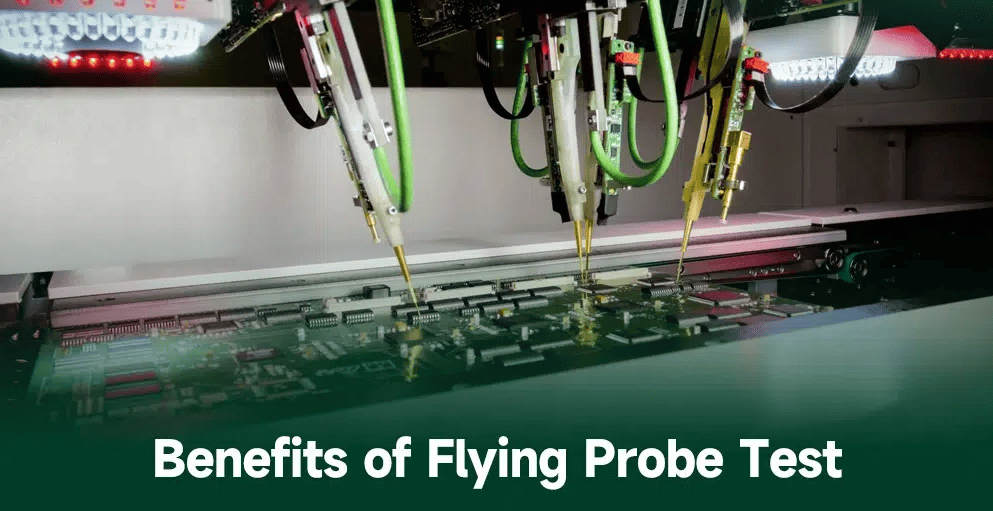

What is Flying Probe Testing for Prototyping and Low-Volume PCB Production?

Advantages:

- Lower initial cost: No fixture needed, reducing upfront expenses, ideal for low-cost PCB testing.

- High adaptability: Accommodates design changes easily without the need for fixture reconfiguration.

- Ideal for complex designs: Suitable for intricate circuits that require flexible, fixture-free testing.

Limitations:

- Slower testing speed: Sequential (point-by-point) testing takes longer than parallel testing.

- Moderate accuracy for high-density boards: Moving probes may struggle with very small test pads, affecting accuracy.

Use Cases:

Preferred in medical device prototyping and low-volume electronics where flexibility and cost control are crucial, and testing speed is less important.

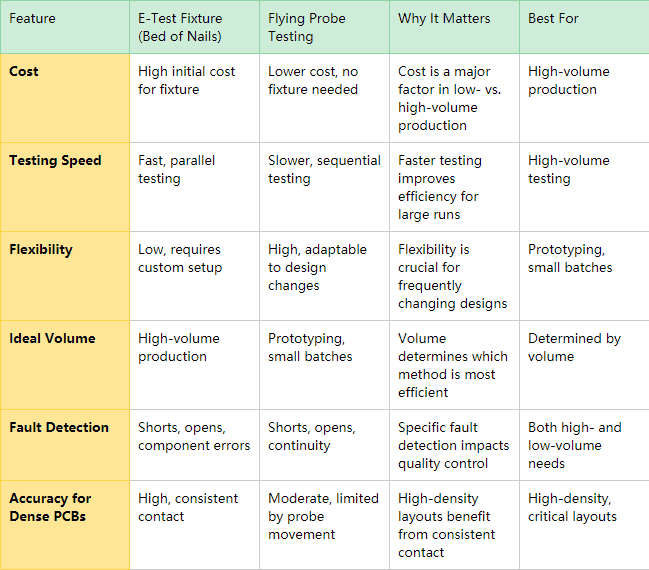

Comparison Table: E-Test Fixture vs. Flying Probe Testing

Types of Faults Detected in PCB Testing

- E-Test Fixture: People use this a lot to check if stuff is connected, if there are shorts, and if the parts are in the right place. You can test a lot of stuff at the same time because the pins touch a lot of points at once, which is good for PCBs with a lot of stuff on them.

- Flying Probe Testing: This way of testing can check if stuff is connected and how much resistance there is by moving probes one at a time to the test points. This way is good for testing prototype circuits when you need to change your design a lot.

Cost and ROI Considerations for PCB Testing Methods

- E-Test Fixture: Even though it costs a lot to set up, this way of testing is a good deal when you’re making a lot of PCBs. For example, if it costs $5,000 to set up the fixture, it might be a good deal if you’re making more than 10,000 PCBs because it saves you time and money on people.

- Flying Probe Testing: This way of testing doesn’t cost a lot to set up, and you can change it, so it’s good for making a few or just one. This way doesn’t cost a lot to change, so it’s good for when you’re just starting out.

Tip: If you’re changing your design a lot, you might want to use flying probe testing so you don’t have to spend a lot of money changing the fixture. If you’re making a lot of the same thing, you might want to use an E-test fixture because it’s faster, you can make a lot of stuff at once, and it’s cheaper in the long run.

Decision-Making Guide: Which PCB Testing Method is Right for You?

- High-Volume, Stable Designs: Use an E-test fixture for rapid, scalable testing.

- Prototyping and Low-Volume Production: Choose flying probe testing to save on setup costs and gain flexibility.

- Frequent Design Changes: Opt for flying probe testing to avoid reconfiguration costs associated with custom fixtures.

- Complex, High-Density Boards: E-test fixtures offer the accuracy needed for precise contact on densely packed layouts.

Practical Use Cases for E-Test Fixtures and Flying Probe Testing

- 1.Automotive High-Volume Production: For example, a big car company that makes PCBs for the stuff that keeps you safe in your car might use E-test fixtures to make sure that every PCB is good enough to keep you safe, so they don’t have to stop making stuff.

- 2.Medical Device Prototyping: A medical company that’s making a thing you wear to check your heart might use flying probe testing to test stuff fast and change it a lot to make sure it’s right when they’re making a few of them.

- 3.Consumer Electronics with Rapid Design Changes: Companies that make stuff like phones and tablets might use flying probe testing to test stuff when they’re making a few of them and changing it a lot without spending a lot of money to set up the fixture.

Summary: Choosing the Best PCB Testing Method for Your Needs

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFor more information, visit below:

Request for Quote

Assemble 20 PCBAS for $0

RECENT POSTS

Quick Turn Turnkey PCB Assembly: Fast Quotes, Faster Prototypes, Lower Risk

Quick turn turnkey PCB assembly for engineers who need fast quotes, reliable component sourcing, controlled SMT/DIP processes, and verified prototypes. Reduce risk, avoid platform pitfalls, and move from design to working boards faster.

IC Boards Explained: Applications, Layout Tips, and Assembly Services

Discover what IC boards are, how they’re used in modern electronics, and how to design them effectively. Learn layout tips and explore expert IC board assembly services for faster production.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!