Quick Leads

How Gas Detector Sensor PCBs Ensure Fast Response Times to Gas Leaks?

Gas leaks are a serious hazard in industries such as oil and gas, manufacturing, and confined spaces, where quick detection can prevent disasters. In these environments, gas detector sensor PCBs (Printed Circuit Boards) are critical to ensure that detectors respond quickly to leaks. But how do these PCBs ensure fast detection? This article delves into the technology behind fast response gas sensors, the impact of environmental factors, and the innovations driving faster and more reliable detection times.

Gas detector PCBs ensure fast response times by continuously monitoring gas levels and sending real-time data to the detection system. This helps activate alarms or safety protocols instantly, preventing potential hazards and ensuring a safer working environment.

But beyond this basic function, how do gas detector PCB designs handle variations in environmental conditions? And what technological advancements are improving their performance in fast gas leak detection?

What is the Response Time of a Gas Sensor?

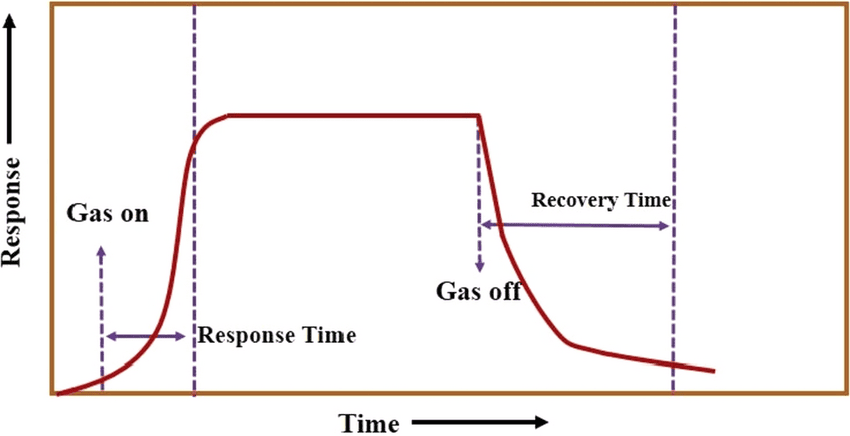

In the world of gas leak detection, the response time of a gas sensor is critical. It refers to the time it takes for a sensor to detect a gas leak and provide a reliable reading of the gas concentration. Typically measured by the time it takes the sensor to reach 90% (T90) of the final concentration after exposure to the gas, the response time ranges from 10 to 20 seconds for most detectors.

The faster the response time, the faster the detection system can trigger alarms or safety measures, which are critical for preventing accidents. Factors such as the sensor’s sensitivity, the PCB’s performance for gas detection, and the type of gas involved all affect how quickly the sensor reacts.

The gas detector PCB design is critical to making sure that all of these sensor types send signals to the monitoring system without delay.

How Do Gas Detector Sensors Work?

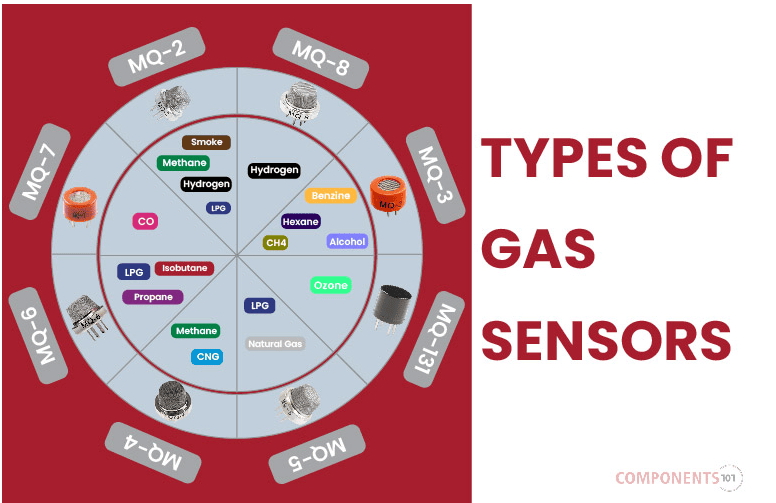

There are a few different types of gas detector sensors, and each one works a little differently. The most common type of sensor used in gas detection systems is an electrochemical sensor. These sensors work by detecting gas molecules through a chemical reaction that happens on the surface of an electrode. The sensor creates an electrical current based on this reaction, and the PCB processes this signal and sends it to the system.

The job of the gas detector PCB design is to take that signal and process it quickly and accurately. If there is any delay in the response of the PCB, it could slow down the detection, so it’s critical to have high-performance PCB designs to make sure that you have fast response times to gas leaks.

What Leak Detection Methods Are Used to Detect Gas Leaks?

Various methods are employed to detect gas leaks, each with its own advantages:

- Pellistor/Cat Bead Sensors: Detect temperature changes caused by the presence of gas. When gas comes in contact with a heated bead, it changes the bead’s temperature, which triggers a response.

- Infrared Sensors: These sensors detect specific gases by measuring the absorption of infrared light at certain wavelengths. This allows for accurate and fast leak detection.

- Electrochemical Sensors: These sensors detect the presence of gases through a chemical reaction that happens at the electrodes on the sensor. The PCB performance for gas detection ensures that this data is processed quickly so that you can take action right away.

How Do Environmental Factors Impact Gas Detector Sensor Response Times?

Environmental conditions can have a big effect on how well gas detectors work. Temperature, humidity, and changes in atmospheric pressure can all affect how quickly a gas leak detection sensor picks up a leak.

- Temperature:Extreme temperatures can make sensors less accurate, which can affect how quickly they respond and how well they can detect leaks. Very low or high temperatures can slow down the chemical reactions inside electrochemical sensors, which can make it take longer for the sensor to detect a gas leak.

- Humidity: High humidity can mess with the gas molecules in the air, which can mess with the sensor’s ability to detect certain gases. This can make it take longer for the sensor to respond or give you a false reading.

- Pressure: Changes in atmospheric pressure can mess with gas concentration readings, especially in tight spaces. PCBs designed to account for these changes help keep the readings accurate and make sure the sensor responds quickly even when the environment is tough.

The PCBs in gas detector sensors are designed to handle these things, but if the environment gets really extreme, you may need to recalibrate the sensor or adjust it more often.

To learn more about how environmental factors affect sensor accuracy, see Environmental Factors Impacting Sensor Accuracy.

What Innovations Are Improving the Response Time of Gas Detector PCBs?

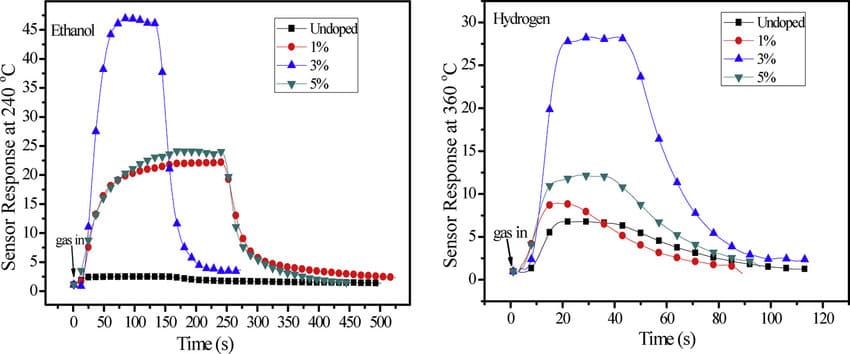

Advancements in both PCB design and sensor technology are improving response times for gas leak detection. Some notable innovations include:

- High-Sensitivity PCBs: These designs can detect even tiny amounts of gas, which means the sensors can respond faster and more accurately to leaks. By making the PCBs more sensitive, gas detectors can react right away to low levels of dangerous gases, so you don’t have to wait for the sensor to catch up.

- Real-Time Data Transmission: New technologies in real-time monitoring have allowed gas detectors to send and receive data instantly. This means there’s less time between when the sensor picks up the gas and when you can do something about it, which makes you safer in places where gas levels change fast.

- Integrated Amplification Circuits: The PCB design has amplification circuits that make sure the sensor’s signal gets processed and sent out right away, which means the system reacts a lot faster.

For more insights into the innovations in PCB design for industrial applications, see Innovations in PCB Design for Industrial Applications.

How Do Gas Detector PCBs Help in Real-Time Monitoring?

Real-time monitoring is a critical part of modern gas detection systems. The gas detector PCBs ensure that the sensor data is processed and transmitted immediately to the monitoring unit. This is important because it allows the alarms to be triggered and the safety measures to be activated as quickly as possible.

In environments where continuous gas monitoring is necessary—such as in chemical plants or refineries—fast response gas sensors integrated with real-time data transmission can instantly alert operators to changes in gas concentrations, helping them take quick corrective actions.

How Does Fast Response Impact Gas Leak Safety?

The faster a gas detection system can react, the faster you can activate safety protocols like alarms, ventilation systems, or shutting down processes. The PCB performance for gas detection makes sure that this reaction time is as short as possible, so you get real-time alerts and maybe save lives.

Why is Gas Detector PCB Sensitivity Crucial for Fast Response Times?

The sensitivity of the gas detector PCB design is critical to fast detection and response. A highly sensitive PCB can detect even low levels of dangerous gases, triggering alarms before the gas gets to dangerous levels. With higher sensitivity, gas detectors can respond to leaks before they become a big problem, so you can take action sooner and reduce the chances of being exposed to dangerous gases. This is especially important in places where the gas levels change a lot and you need to know right away.

So, gas detector sensor PCBs are a big deal when it comes to fast response times in gas leak detection systems. By putting high-sensitivity sensors together with cool PCB designs and real-time monitoring technology, we’re making these systems faster and more accurate. But you still have to think about things like temperature, humidity, and pressure to make sure the sensors work right.

If you are looking for custom PCB solutions that optimize response times for gas detection, contact us today to discuss how we can enhance your system’s performance.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!