Quick Leads

How Gas Detector Sensor PCBs Monitor Carbon Leakage in Storage?

What Does a CO2 Gas Sensor Do in Industrial Settings?

What Does a Carbon Dioxide Gas Sensor Monitor?

- Breweries: Monitoring CO2 during fermentation.

- Agriculture: Managing greenhouse CO2 levels for optimal plant growth.

- HVAC Systems: Maintaining air quality and ventilation efficiency.

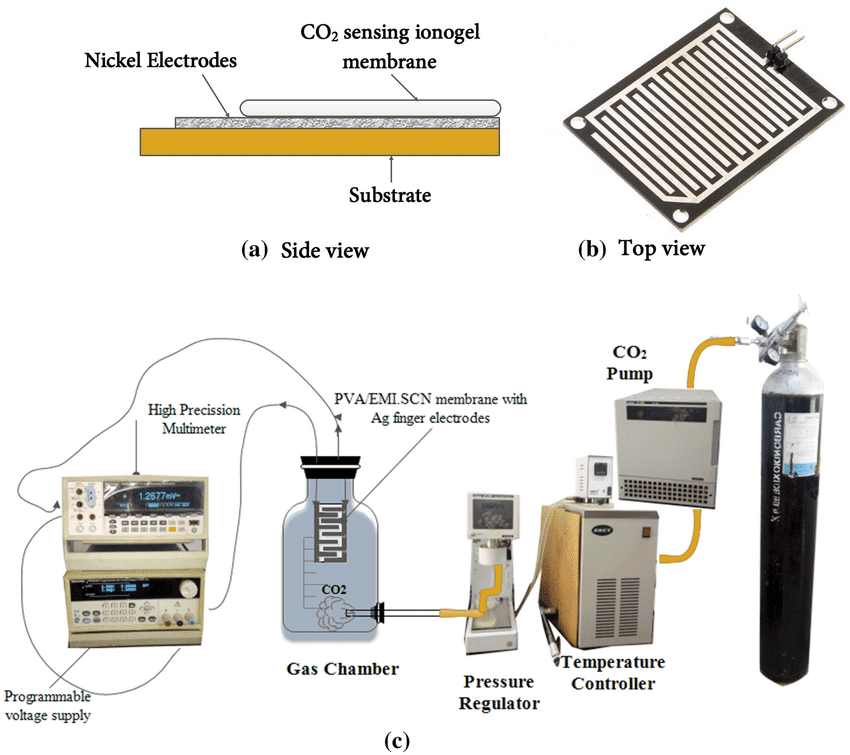

CO2 Sensor Technology Overview

- Infrared Sensors: These sensors work by measuring how much infrared light is absorbed by the gas. They are highly accurate and can detect even small concentrations of CO2 over long periods, making them ideal for industrial environments.

- Electrochemical Sensors: These sensors rely on redox reactions to detect the presence of gases. They are particularly useful in low-level CO2 detection and are often found in environments where high sensitivity is required.

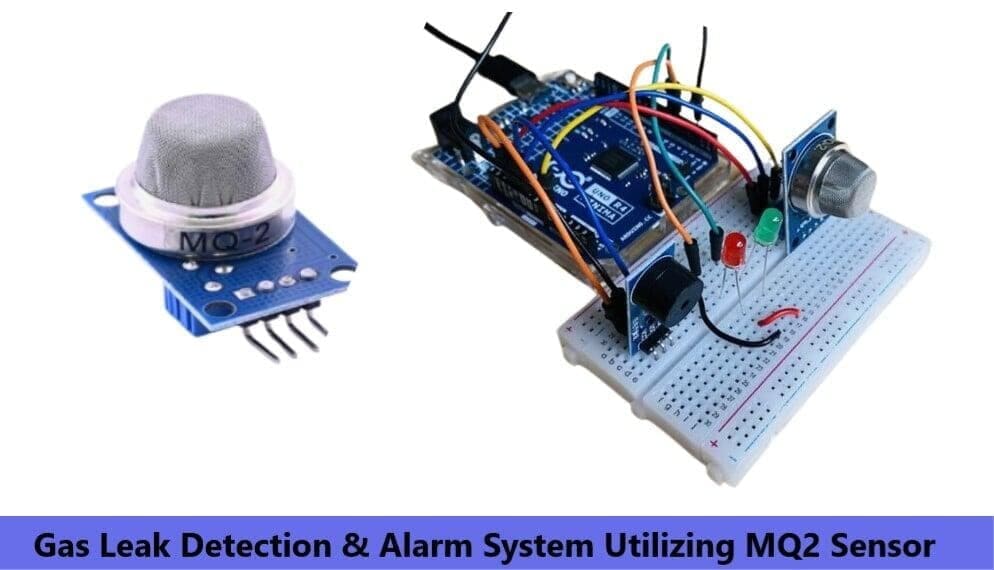

What is the Purpose of a Gas Leakage Detection System?

- Monitoring gases like CO2, methane, and ammonia.

- Triggering alarms or alerts when gas levels reach dangerous concentrations.

- Allowing immediate intervention to prevent accidents.

Gas Leak Detection Technology

- Electrochemical Sensors: These sensors are widely used to detect toxic gases like carbon monoxide and nitrogen dioxide. In environments such as warehouses or manufacturing facilities, electrochemical sensors integrated into gas detector PCBs provide quick and accurate feedback, reducing the risk of hazardous incidents.

- Infrared Sensors: Known for their ability to measure gases like CO2 accurately, infrared sensors are commonly used in HVAC systems, refrigeration units, and chemical plants.

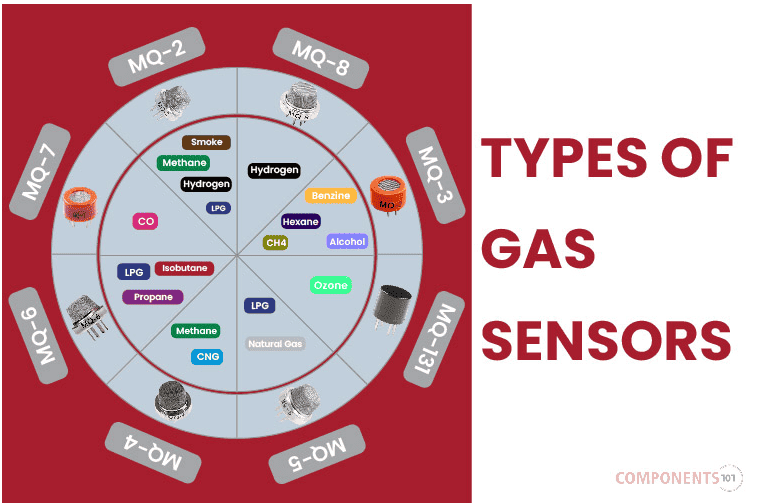

What Types of Gases Can Gas Detector Sensor PCBs Detect?

- Carbon Dioxide (CO2): Found in refrigeration and fermentation processes.

- Methane (CH4): Present in natural gas and petrochemical industries.

- Ammonia (NH3): Common in agricultural refrigeration systems.

- Carbon Monoxide (CO): Detected in industrial environments, especially in confined spaces.

How Do Gas Detector Sensor PCBs Work for Carbon Leakage in Storage?

- Gas Detection: Integrated sensors detect gases like CO2 through technologies like infrared or electrochemical sensors.

- Signal Processing: The PCB amplifies and processes the signal to ensure accurate readings.

- Alarm Trigger: If the gas concentration exceeds safe levels, the PCB activates an alarm to alert personnel.

What Are the Common Applications of Gas Detector Sensors in Industrial Environments?

- Oil and Gas Industry: Monitoring toxic gases like hydrogen sulfide and methane to prevent explosions.

- Chemical Manufacturing: Ensuring safe chemical production by detecting ammonia and chlorine leaks.

- Mining: Protecting workers from dangerous methane and carbon monoxide leaks in mines.

- HVAC: Managing indoor air quality by detecting harmful gases in ventilation systems.

Why Are High Sensitivity PCBs Important for Gas Detectors?

- They ensure that even trace amounts of dangerous gases like CO2 or methane are detected before they reach hazardous levels.

- These sensitive PCBs enable earlier detection, which helps prevent accidents and ensures compliance with safety regulations.

- In storage facilities, where gas leaks can accumulate unnoticed, high-sensitivity PCBs are essential for real-time monitoring.

How Do Safety Systems Use Gas Detector Sensor PCBs?

- The sensors continuously detect gases like CO2, methane, and ammonia.

- The PCBs process sensor data and trigger alarms when gas levels exceed predefined thresholds.

- These systems provide real-time data to ensure that personnel can take swift action to mitigate risks and prevent accidents.

Summary

Frequently Asked Questions (FAQs)

Gas detector sensors work by detecting specific gases in the air and triggering an alarm when dangerous levels are detected. The sensors, such as infrared or electrochemical sensors, detect changes in gas concentration and send this information to the sensor’s PCB (printed circuit board), which processes the data and activates an alert system if the gas levels exceed a safe threshold. These sensors are crucial in industries where gas leaks could pose significant health or safety risks.

The most accurate CO2 sensors for storage facilities are infrared (IR) sensors. These sensors measure how much infrared light is absorbed by CO2 molecules. The high sensitivity of infrared sensors makes them ideal for monitoring CO2 levels in environments such as refrigeration units, chemical plants, and breweries, where precise monitoring is critical.

CO2 monitoring is critical in industrial safety because excessive CO2 concentrations can be dangerous. In environments such as chemical plants or refrigeration systems, elevated CO2 levels can lead to suffocation, explosions, or even death if not properly detected. By using gas detectors with integrated PCBs, real-time monitoring ensures that any hazardous buildup is promptly identified, reducing risks.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!