Quick Leads

How Multilayer PCBs Revolutionize Medical Equipment Technology in Healthcare

Introduction: The Backbone of Medical Innovation

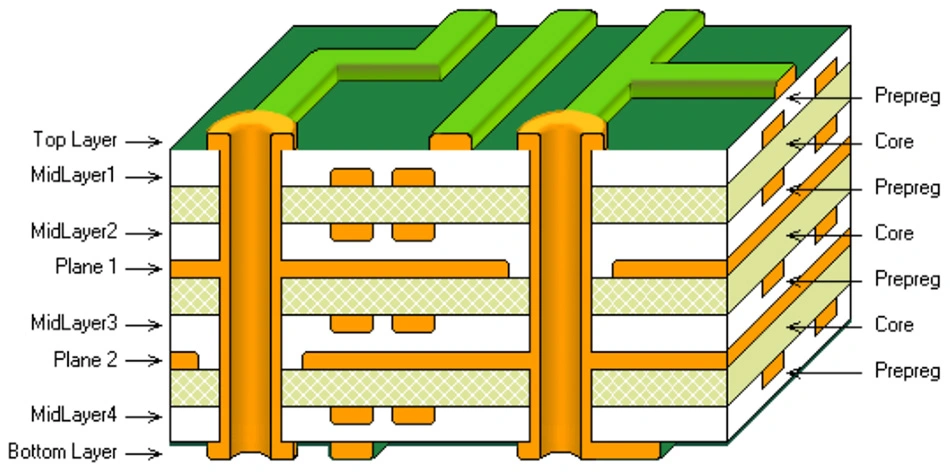

What is the Purpose of a Multilayer PCB?

Technical Advantages:

-

Signal Integrity: Better impedance control means your signals won’t get messed up, which is important for high-frequency medical devices.

-

Thermal Management: Efficient heat dissipation mechanisms make sure things like imaging scanners and surgical instruments don’t break down.

-

Power Distribution: Better current flow between layers means less noise and more efficient devices.

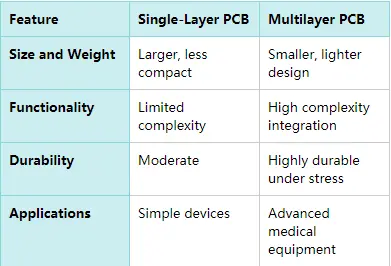

Why Are Multilayer PCBs Better Than Single-Layer Alternatives?

Comparison Table: Single-Layer vs. Multilayer PCBs

How Do PCBs Drive Medical Device Innovation?

1. Diagnostic Accuracy

- Example: In MRI and CT scanners, PCBs make sure your signals are processed correctly, which is important for creating high-resolution images.

- Technical Insight: High-frequency multilayer PCBs handle fast data transmission and keep interference to a minimum.

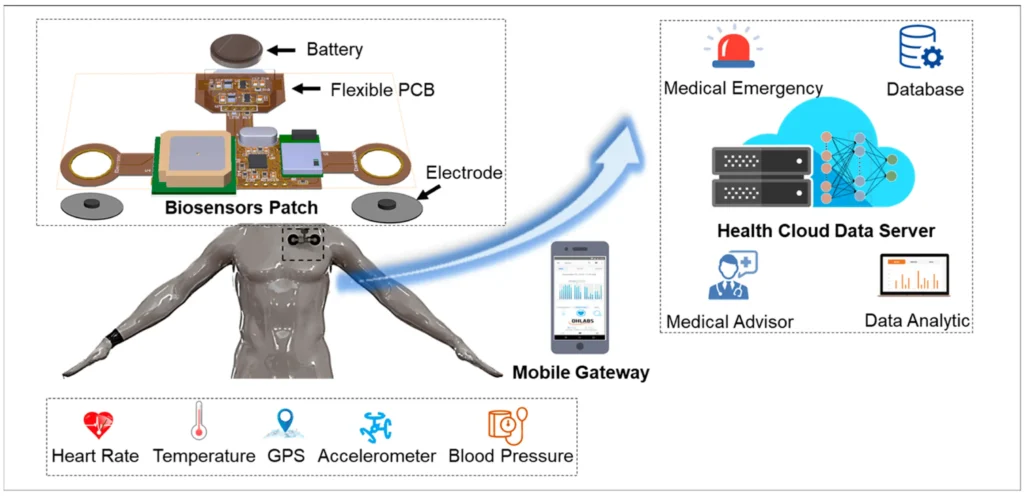

2. Wearable Medical Technology

- Example: Fitness trackers and health monitors use flexible multilayer PCBs so they’re small and comfortable to wear.

- IoT Integration: These devices talk to each other wirelessly, and PCBs make sure they can do that without any problems.

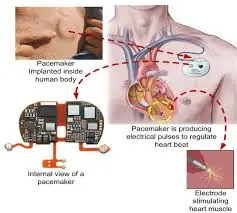

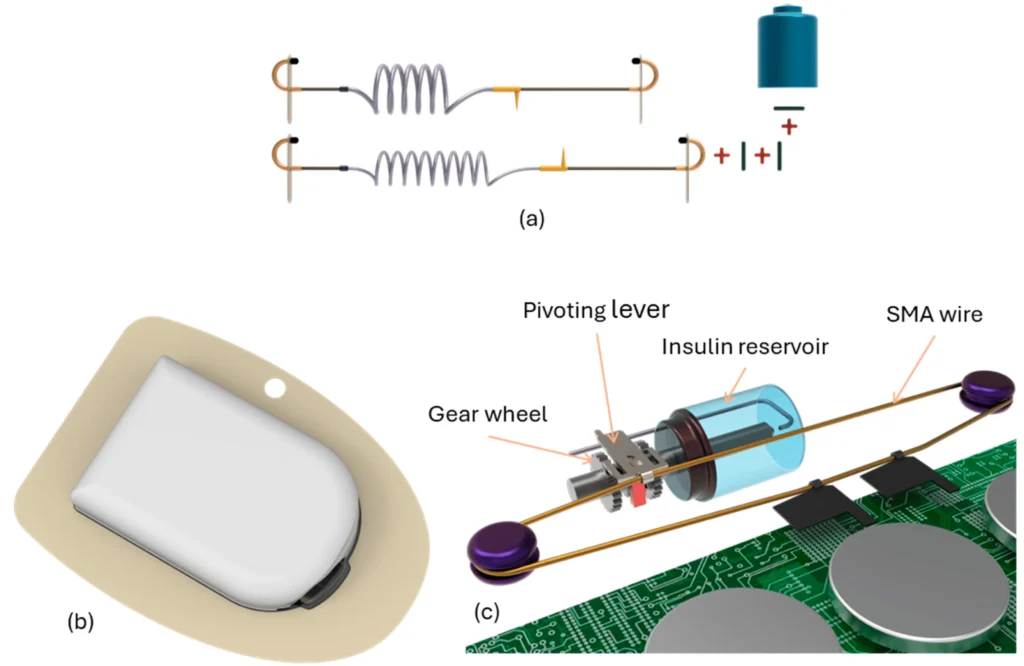

3. Life-Saving Implants

-

Example: Pacemakers and insulin pumps use small PCBs to keep working all the time.

-

Reliability: Multilayer PCBs have extra pathways, so they keep working even if something goes wrong.

Key Trends in Multilayer PCB Design for Healthcare

IoT Integration in Medical PCBs

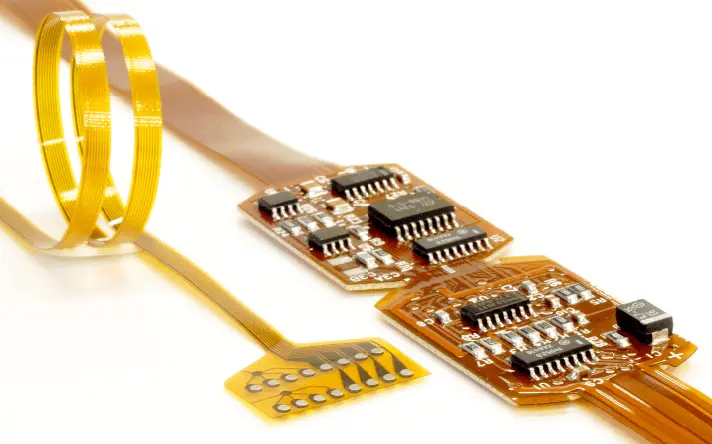

The Rise of Flexible PCBs

Biocompatible and Sustainable Materials

High-Frequency Multilayer PCBs

Real-World Case Study: Compact Insulin Pumps

- Challenge: Designing a small device that gives you the right amount of insulin when you need it.

- Solution: We made a six-layer PCB that got rid of the heat and used less power, so we could make it smaller without losing any performance.

- Impact: You can move around more and do what you want, and it’s easier to take your medicine.

For more information, visit below:

Frequently Asked Questions (FAQs)

Multilayer PCBs let us make small, high-density designs for things like imaging systems, implants, and IoT-connected devices.

Some of the things we’re seeing are IoT, flexible PCBs, high-frequency multilayer PCBs, and using materials that are safe inside your body.

IoT-connected PCBs make it possible to monitor you all the time, which helps doctors take care of you and make decisions faster.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary: Bridging Technology and Healthcare

Call to Action

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!