Quick Leads

How to Choose a Reliable PCB Supplier in China: Expert Guide for Electronics Manufacturers

Introduction

Selecting a reliable PCB supplier in China is crucial for any electronics project. China is the world’s leading PCB manufacturer. This means you can get great prices and the latest technology. However, finding the right supplier involves more than just cost considerations. You need to evaluate quality, certifications, lead times, and communication. This guide will show you how to buy PCBs from China. It will help you make smart decisions for your next project.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

The Benefits of Purchasing PCBs from China Suppliers

There are several reasons why you should buy PCBs from China:

-

Cost-Effectiveness: PCB manufacturing in China offers competitive pricing, especially for bulk orders, without compromising quality.

-

Advanced Technology: Chinese PCB manufacturers use cutting-edge technology, capable of producing high-quality multi-layer and HDI boards.

-

Fast Turnaround: China PCB suppliers for electronics are known for their quick delivery times, ideal for tight production schedules.

-

Broad Range of Capabilities: Whether you need prototypes, low-volume production, or complex PCB designs, Chinese suppliers can handle a wide variety of needs.

Choosing the right supplier ensures that you benefit from competitive pricing and high-quality production for your PCB needs.

10 Key Factors to Evaluate When Selecting a PCB Supplier in China

When selecting a PCB supplier, it’s essential to evaluate several key factors to ensure the best quality and service. Here are 10 critical factors to keep in mind:

-

Certifications and Quality Standards: Look for suppliers with relevant certifications like ISO 9001, UL, and RoHS to guarantee quality compliance.

-

Experience and Reputation: Choose a supplier with a strong reputation and extensive experience in PCB manufacturing.

-

Capabilities: Ensure the supplier can handle your specific design requirements, whether simple or complex.

-

Pricing Transparency: Compare pricing across different suppliers and ensure that the quote includes all costs.

-

Lead Times: Confirm that the supplier can meet your delivery deadlines, especially for time-sensitive projects.

-

Supply Chain Reliability: Make sure the supplier has a reliable supply chain for sourcing components and materials.

-

Customer Support: Evaluate the level of customer support the supplier offers, including communication during production.

-

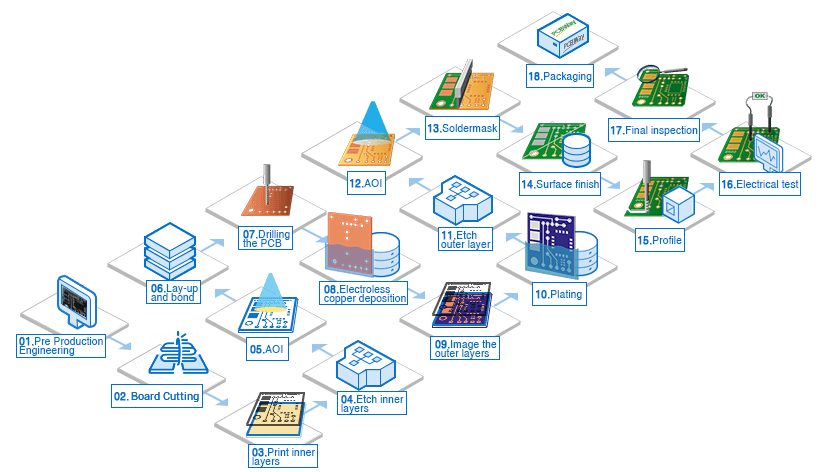

Testing and Quality Control: Ensure the supplier has rigorous testing protocols in place, such as visual inspection and electrical testing.

-

After-Sales Service: Verify the supplier provides post-production support, including handling defective products.

-

Flexibility: A reliable supplier should be flexible enough to adapt to changes in order volume or design specifications.

By considering these factors, you’ll find a supplier that aligns with your needs and ensures quality results.

How to Verify PCB Supplier Credibility

Verifying the credibility of your PCB supplier in China is essential to avoid costly mistakes. Follow this checklist to ensure that your supplier is trustworthy:

Request Certifications: Ask for certification documents like ISO 9001, RoHS, and UL to verify compliance with international standards.

Ask for References: Request customer references or case studies to evaluate the supplier’s performance and reliability.

Factory Inspection: If possible, conduct a factory audit or request information about their production capabilities.

Sample Testing: Request samples to evaluate their quality before placing a bulk order.

Communication and Responsiveness: Assess the supplier’s communication, response times, and willingness to address your concerns.

Financial Stability: Ensure the supplier has a solid financial background to handle large orders and maintain operations.

By following these steps, you can verify your supplier’s credibility and make an informed decision.

Tips for Negotiating Your Way to Better Prices with Chinese PCB Suppliers

Negotiating with Chinese PCB suppliers can help you get the best pricing and terms for your project. Here are some expert tips to negotiate more effectively:

-

Bulk Orders: Negotiate better prices by purchasing in larger volumes or committing to long-term contracts.

-

Discount for Long-Term Relationships: Suppliers may offer discounts or better terms for long-term partnerships.

-

Flexible Payment Terms: Try negotiating for extended payment terms or early payment discounts to help manage cash flow.

-

Request for Quotes (RFQ): Use multiple suppliers to get quotes and compare pricing and terms.

-

Consolidated Shipments: Consolidate your orders into one shipment to reduce shipping costs.

Effective negotiation ensures you get the best deal without sacrificing quality or service.

How to Identify Quality Components from Chinese PCB Suppliers

Identifying high-quality components is critical to ensuring your PCBs perform reliably. Here’s how to identify quality components from Chinese PCB suppliers:

-

Component Traceability: Ensure the supplier uses traceable components with a clear history.

-

Request Documentation: Always ask for RoHS and UL certifications to verify component quality.

-

Sample Testing: Before placing large orders, always request samples and test the components for quality.

-

Trusted Brands: Work with suppliers who use reputable, industry-standard component brands.

-

Reliability Testing: Request reliability testing (such as thermal cycling or environmental stress tests) to ensure component performance.

By focusing on component quality, you ensure that your PCB performs reliably in real-world applications.

Avoiding Common Mistakes When Sourcing PCBs from China

Here are some common mistakes to avoid when sourcing PCBs from China, along with tips on how to prevent them:

Choosing Based Solely on Price: Don’t compromise quality for a lower price. Always balance cost with quality.

Overlooking Communication: Ensure consistent and clear communication throughout the sourcing process.

Neglecting Sample Testing: Always request samples before making large orders to ensure the quality meets your expectations.

Not Verifying Lead Times: Confirm that the supplier can meet your deadlines, especially for urgent projects.

Ignoring After-Sales Service: Always ensure that the supplier offers robust after-sales support for defect resolution and troubleshooting.

Avoiding these mistakes helps you select a supplier who delivers both on time and on quality.

Industry Trends and Innovative Technologies in PCB Manufacturing

The PCB manufacturing industry is constantly evolving, driven by technological innovations and changing market demands. Here are some key industry trends and innovative technologies shaping the future of PCB manufacturing:

-

Flexible PCBs: The demand for flexible and bendable PCBs is growing, particularly in wearable electronics and compact devices.

-

5G Technology: With the rise of 5G technology, high-frequency PCBs are becoming more critical for meeting the stringent performance requirements.

-

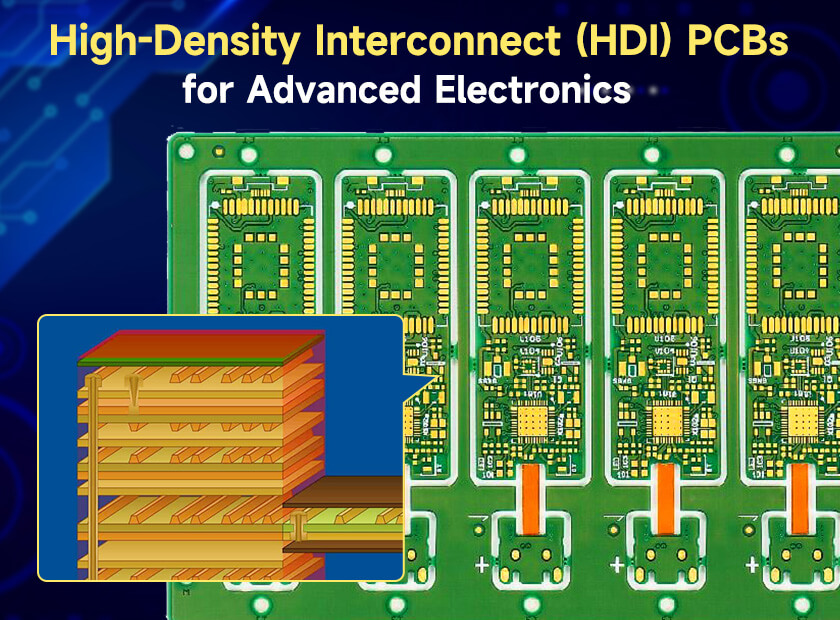

HDI Boards: High-Density Interconnect (HDI) boards are gaining popularity for their ability to pack more functionality into smaller spaces, ideal for smartphones and other compact electronics.

-

Automated Manufacturing: Advanced robotics and automation are being implemented in PCB manufacturing to improve precision, reduce labor costs, and increase production speed.

-

AI and Machine Learning: Artificial intelligence is being used for predictive maintenance, quality control, and optimizing manufacturing processes to reduce defects and waste.

By staying updated with these trends and technologies, you can better assess potential suppliers and ensure they are equipped to handle the latest requirements in PCB manufacturing.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Choosing the right PCB supplier in China can greatly impact your project’s success. By considering factors such as certifications, quality, pricing, and lead times, you can find a reliable supplier who meets your needs. Additionally, staying informed about industry trends and innovative technologies ensures that your PCB designs are always at the cutting edge.

If you’re ready to find a trusted PCB supplier in China for your next project, contact us today for a tailored quote.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!