Quick Leads

How to Design Reliable and Cost-Effective PCBs for Harsh Environments: A Guide for Startups?

Designing PCBs for extreme conditions can be tough for startups. You need a partner who understands the challenges of high-performance, flexible, and cost-effective solutions. But at the same time, you need flexibility—whether that’s in material sourcing, using flexible PCBs, or accommodating your no minimum order quantity (MOQ) requirements. With the right supplier, you can save time and money while ensuring your products thrive in the harshest environments.

Designing PCBs for harsh environments requires careful consideration of materials, thermal management, and flexibility. For extreme temperatures, you’ll need materials with a high glass transition temperature (Tg), such as high-performance FR4 or polyimide. For designs that require bendability and resistance to mechanical stress, you may need flexible PCBs. A good supplier will not only help you with material sourcing but also provide flexible solutions to help you scale without MOQ requirements.

Designing PCBs for extreme conditions might seem overwhelming, but working with the right supplier can make it easier. Let’s dive into the critical factors you need to consider to make sure your design meets the environmental demands.

How do People Design PCBs for Extreme Conditions?

When designing for harsh environments, choosing the right materials is essential. Here are the top considerations:

- High Tg Materials: FR4 is a commonly used material, but for demanding conditions, you may need polyimide, which offers superior thermal stability.

- Flexible PCBs: If your design requires flexibility or the ability to endure mechanical stress, polyimide-based flexible PCBs are often the best choice.For more information on polyimide flexible PCBs,

check out this guide.

A reliable PCB supplier will guide you through sourcing these materials and creating a prototype that meets extreme environmental requirements.

Check out our range of flexible PCBs.

Check out our range of flexible PCBs.

What Are the Golden Rules of PCB Design for Harsh Environments?

The following design principles are crucial for ensuring your PCBs perform reliably in extreme conditions: Learn about thermal management in PCB design from IEEE.

- Grid Spacing and Component Placement: Proper spacing is necessary to avoid signal interference or short-circuiting, especially in high-voltage areas.

- Thermal Management: Using thicker copper layers helps with heat dissipation. Additionally, selecting components rated for high temperatures ensures stability.

- Moisture and Chemical Resistance: To protect against corrosion and environmental factors like moisture, apply conformal coatings such as acrylic or silicone.

What Materials Are Best for PCBs in Extreme Environments?

Here are the materials most suitable for extreme conditions:

- High-Performance FR4: Ideal for many applications due to its stability and affordability.

- Polyimide for Flexible PCBs: Best for applications requiring flexibility, high-temperature resistance, and mechanical stress tolerance.

- Halogen-Free Epoxy Resins: These materials are excellent for moisture resistance, making them perfect for humid or corrosive environments.

- Ceramic-Based PCBs: Designed for applications needing high thermal resistance.

Using conformal coatings like epoxy or silicone adds an extra layer of protection against environmental damage.

How Do I Choose a PCB Supplier for My Startup Needs?

Choosing the right PCB supplier is critical to your success. The right supplier will offer:

- Flexible Solutions: No MOQ requirements and the ability to scale production based on your startup’s specific needs.

- High-Quality Materials: A supplier who specializes in sourcing materials like polyimide flexible PCBs and halogen-free epoxy resins.

- Technical Support: An experienced supplier who can guide you through the entire process, from design to production, ensuring your product is both reliable and cost-effective.

A trusted supplier will help you with material selection and design, saving you time and money.

What Are the Key Challenges of PCB Design for Harsh Environments?

Designing for extreme environments comes with unique challenges:

- Thermal Management: Selecting materials that can endure high temperatures without degradation is critical. High-Tg FR4 or polyimide are often necessary.

- Component Durability: Components must be chosen for their ability to resist temperature fluctuations, shock, and vibration.

- Moisture & Corrosion Resistance: In challenging environments, the materials must be resistant to moisture, corrosion, and oxidation.

Working with a reliable PCB supplier will help you address these challenges by selecting the right materials and manufacturing processes to ensure durability.

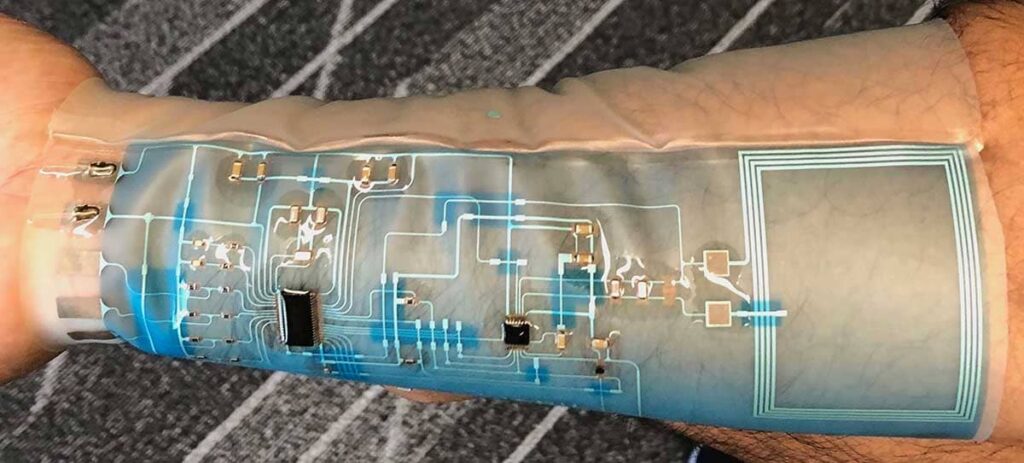

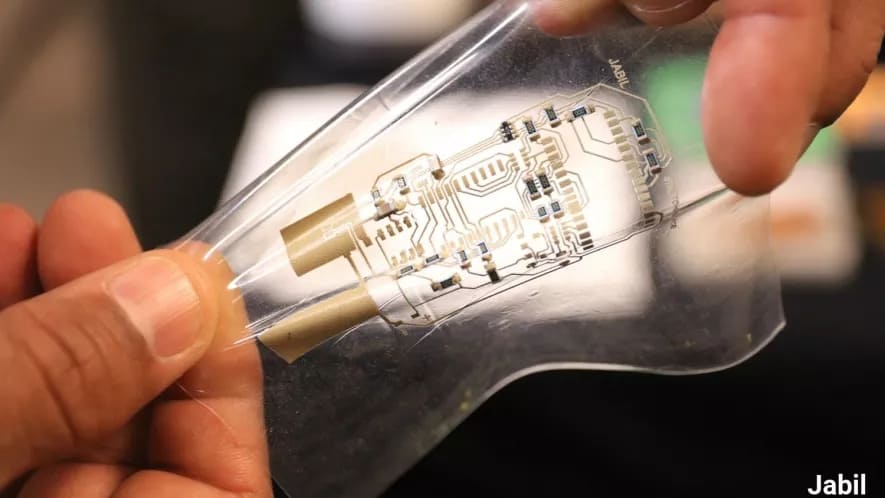

Flexible PCBs: Advantages in Extreme Conditions

Flexible PCBs made from polyimide or similar materials offer several advantages, including:

- Compact Design: Flexible PCBs can bend and fit into tight spaces, making them perfect for wearable or portable devices.

- Durability: These PCBs are resistant to mechanical stress, temperature extremes, and vibration.

- Cost-Effectiveness: Flexible PCBs are often cheaper than traditional rigid boards, especially in low-volume production.

Flexible PCBs are commonly used in automotive, aerospace, and wearable electronics where reliability in extreme conditions is critical.

Learn more about our PCB assembly services.

Learn more about our PCB assembly services.

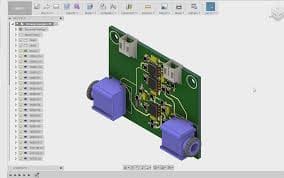

How to Design PCBs for Harsh Environments Online?

Designing PCBs for extreme conditions is easier with modern software tools:

- CAD Tools: Use Autodesk Fusion 360 or Altium Designer, which allow you to simulate your design’s performance in extreme environments before production.

- Collaborate with Suppliers: Many PCB suppliers offer online platforms for design, prototyping, and testing. Working closely with a supplier ensures that your design is feasible and optimized for harsh conditions.

By using these tools, along with expert collaboration, you can ensure your PCB design will meet the demands of extreme environments.

Summary

When you’re designing PCBs for harsh environments, you need to know your materials, thermal management, and durability. Startups need to find a reliable PCB supplier that offers flexible solutions, quick turnaround, and no MOQ requirements. By using the right materials and design techniques, you can make sure your PCBs will perform reliably in extreme conditions.

Ready to design your PCBs for extreme environments?

Contact us today for expert advice and cost-effective solutions tailored to your startup’s needs! Whether you need flexible PCBs, high-temperature materials, or moisture-resistant designs, we have the expertise to help your products perform under any condition.

Contact us today for expert advice and cost-effective solutions tailored to your startup’s needs! Whether you need flexible PCBs, high-temperature materials, or moisture-resistant designs, we have the expertise to help your products perform under any condition.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!