Quick Leads

Industrial PCBs: Comprehensive Guide to Design and Manufacturing

Introduction

Industrial PCBs (Printed Circuit Boards) are the backbone of industrial electronics, used in a wide range of sectors like automation, robotics, medical devices, and more. These highly durable, efficient, and customizable boards ensure seamless functionality in critical applications. In this guide, we’ll cover the fundamentals of industrial PCB design, materials, and manufacturing processes, helping engineers and designers create PCBs that meet rigorous standards.

What Are Industrial PCBs?

Industrial PCBs are specialized printed circuit boards designed for use in industrial environments. Unlike consumer PCBs, industrial PCBs are built to handle harsher conditions, including extreme temperatures, vibrations, and exposure to various chemicals. They are often used in applications requiring higher reliability and durability.

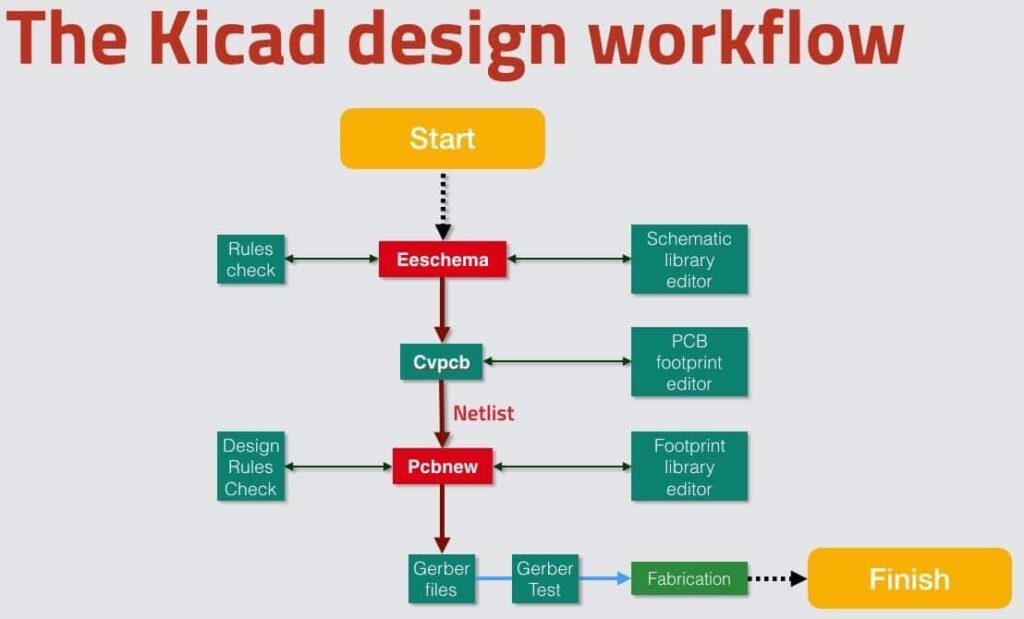

Step-by-Step Guide to PCB Design

Designing an industrial PCB involves several stages. It’s essential to focus on both the functionality and durability of the PCB, ensuring it can perform reliably in its intended environment. Here’s a step-by-step guide to designing an industrial PCB:- Schematic Design

- Component Selection

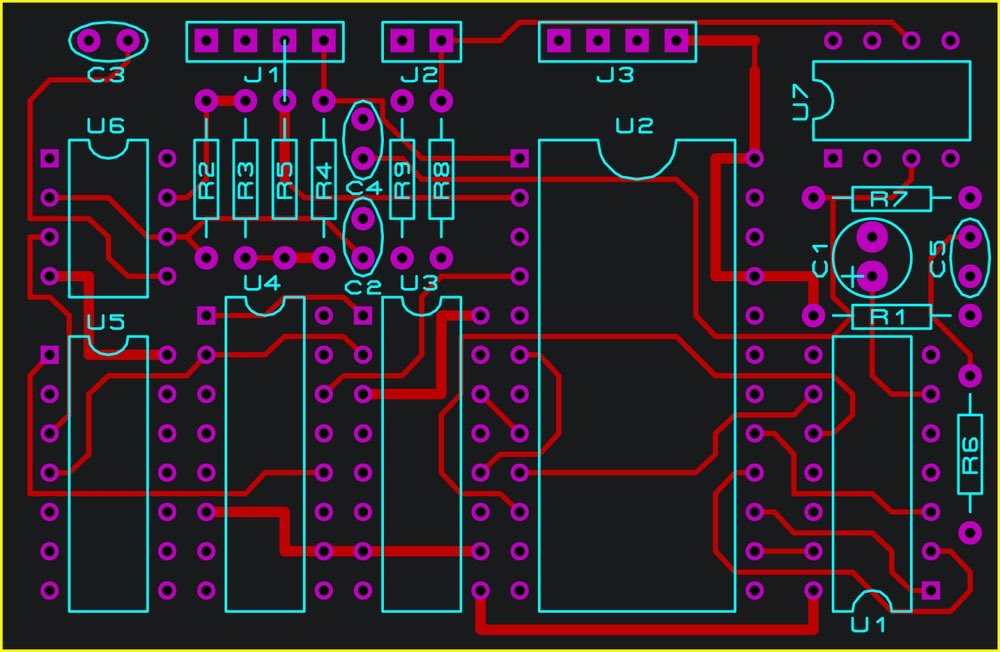

- PCB Layout Design

- Design Rule Check (DRC)

- Gerber File Generation

- Prototyping and Testing

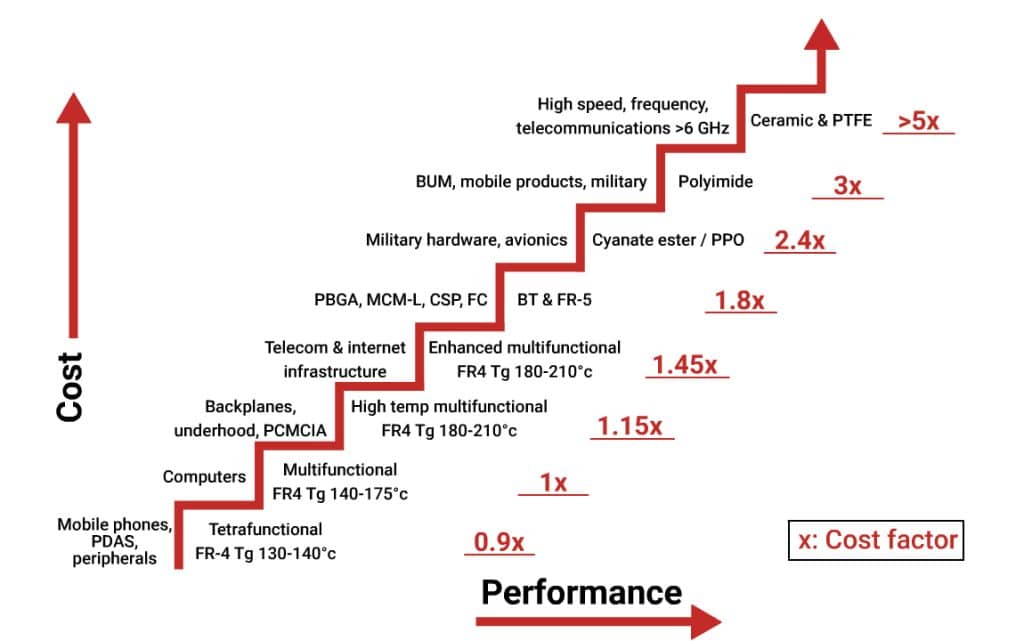

Selecting the Right Materials for Industrial PCBs

The material selection for industrial PCBs plays a crucial role in ensuring the board’s performance under harsh conditions. Common materials used include:

- FR4 (Flame Retardant 4): A widely used material for standard PCBs.

- Ceramic: Ideal for high-frequency applications.

- Teflon: Offers low-loss characteristics and high-temperature resistance.

For more details,please visit PCB Materials

Designing the PCB Layout

The layout is the heart of the PCB. It defines how the components are placed and interconnected. Key considerations during the layout design include:- Component Placement: Efficient placement of components for ease of manufacturing and effective heat dissipation.

- Trace Routing: Ensuring the routing of traces between components is optimal for performance and reliability.

- Layer Stack-up: Determining the number of layers required for the PCB to ensure compactness and performance.

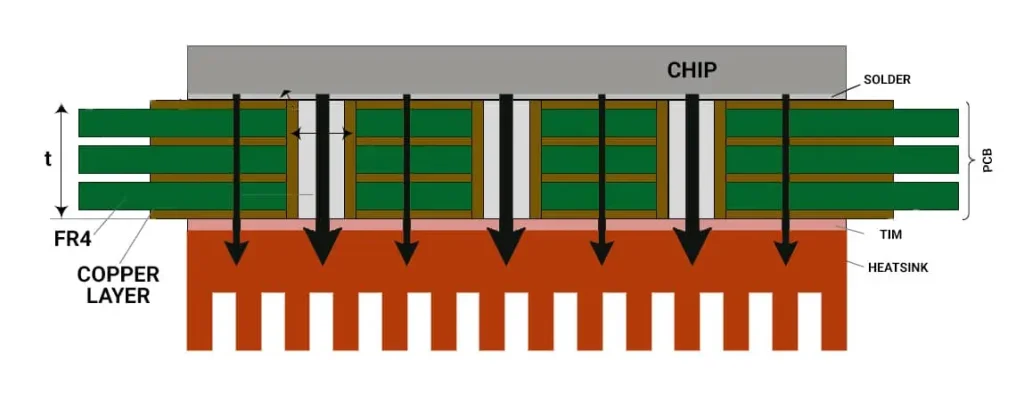

Thermal Management in PCB Design

Thermal management is a critical aspect of industrial PCB design. Proper thermal management ensures that the PCB can handle high temperatures without compromising performance. Techniques include:- Heat sinks

- Thermal vias

- Copper planes

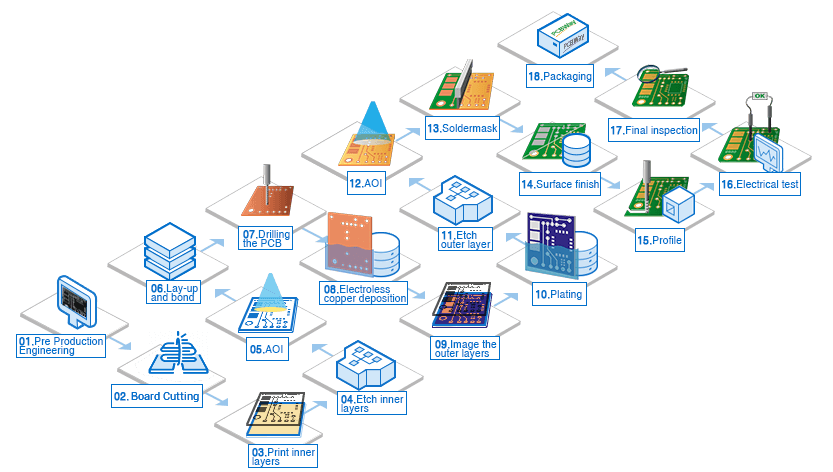

Simplified PCB Manufacturing Process for Industrial PCBs

The PCB manufacturing process involves several stages, from material preparation to the final assembly. Here’s a simplified breakdown of the process:- Copper Cladding

- Etching

- Drilling

- Plating

- Solder Mask Application

- Silkscreen Printing

- Final Inspection and Testing

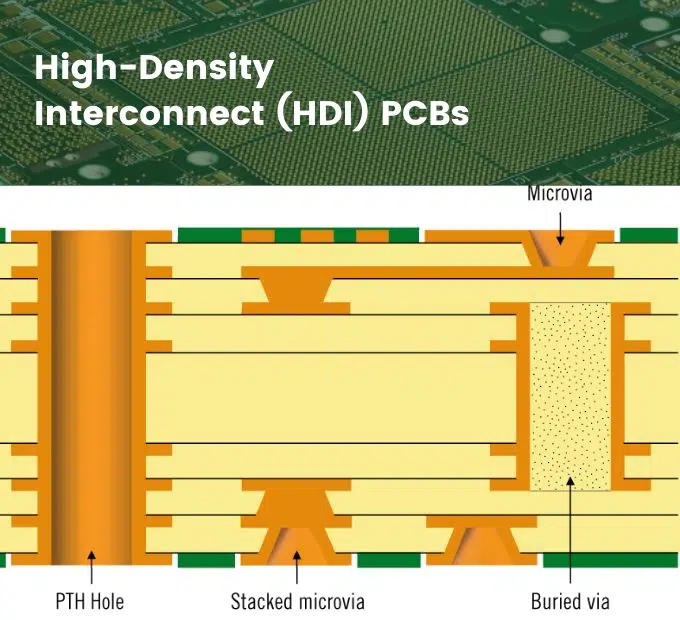

Miniaturization and High-Density PCBs

As industrial applications become more compact, high-density interconnect (HDI) PCBs are increasingly popular. These boards use smaller vias and more layers to increase component density, ideal for miniaturized devices.

Inspection and Testing

Inspection and testing are essential to ensure the quality and reliability of the PCB. Automated Optical Inspection (AOI) and electrical testing help detect defects such as short circuits and open traces.

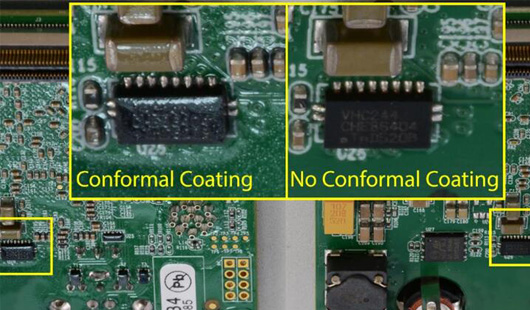

Conformal Coating for Protection

Industrial PCBs often require a protective conformal coating to safeguard them against moisture, dust, and chemicals, especially in harsh environments.

More details on Conformal Coating.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!