Quick Leads

Best PCB Inspection Methods for PCBA Quality Assurance

Best PCB Inspection Methods for Your Assembly

-

Visual Inspection: This is a simple method typically used for low-volume runs or basic assemblies.

-

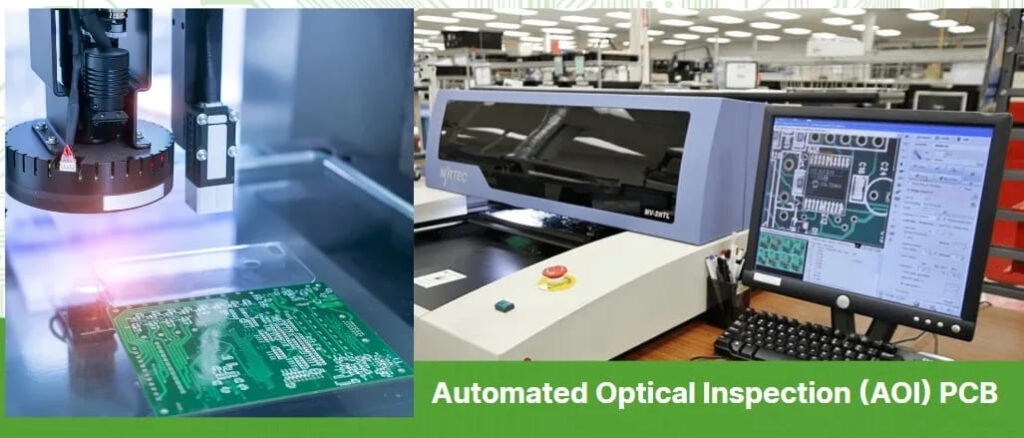

Automated Optical Inspection (AOI): This automated method uses cameras to detect defects like misplaced components or soldering issues.

-

In-Circuit Testing (ICT): A thorough method for detecting faults in components, suitable for high-volume production.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

7 Key PCB Testing Methods Explained

-

In-Circuit Testing (ICT): Tests each component of the board to ensure functionality and detects faults.

-

Flying Probe Testing: Ideal for smaller runs and prototypes, this method involves probes checking electrical connectivity.

-

Automated Optical Inspection (AOI): Uses cameras to check the PCB’s surface for defects, ensuring accurate component placement and soldering.

-

Burn-In Testing: Subjects the PCBA to stress conditions to identify early failure modes.

-

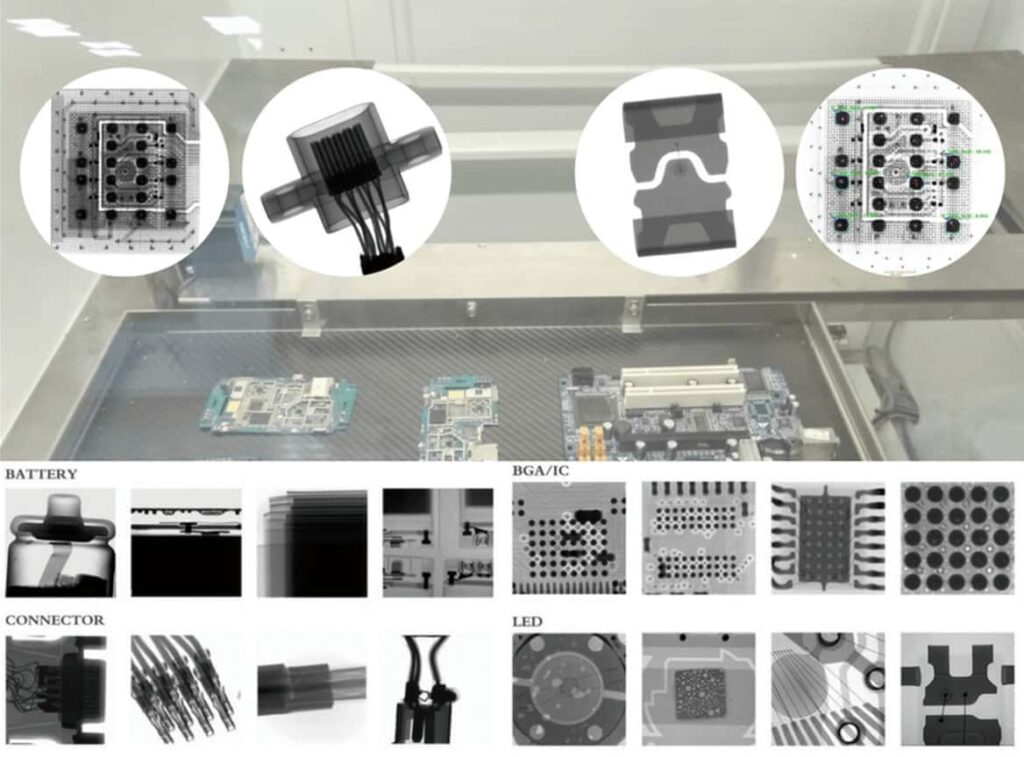

X-Ray Inspection: Detects hidden defects, such as solder joints beneath components or in multilayer PCBs.

-

Functional Testing: Tests the board’s actual function to ensure it operates as intended.

-

Solderability Testing: Checks if the components can be properly soldered to the board, ensuring durability and long-term performance.

How Do You Inspect a PCB?

-

Prepare the PCB: Clean the board to remove any contaminants.

-

Visual Inspection: Look for common defects like misplaced components or cold solder joints.

-

Magnification: Use magnifying tools to examine small components and connections.

What Is the Standard for PCB Inspection?

Which Method Is Used for PCB Board Testing?

How Do I Choose the Best Inspection Method for My PCBA?

-

Assembly Complexity: Simple assemblies may only require visual inspections, while complex boards benefit from automated methods like AOI.

-

Production Volume: High-volume productions are best served by automated methods (AOI and ICT), while smaller runs may rely on manual checks or flying probes.

-

Budget Constraints: While automation requires an initial investment, it often saves money in the long term through increased accuracy and speed.

What Is the Role of Automated Optical Inspection (AOI) in PCBA?

-

Speed: AOI inspects hundreds of boards per hour.

-

Accuracy: It reduces human error and identifies defects that are hard to catch manually.

-

Cost-Effectiveness: Prevents costly recalls and defects, improving overall production efficiency.

How Can I Improve the Efficiency of My PCBA Inspection Process?

-

Investing in Automated Inspection Systems: AOI and ICT can drastically speed up inspections and reduce errors.

-

Standardizing Inspection Procedures: Ensure that all inspection steps follow a standardized process to eliminate inconsistencies.

-

Training Your Team: Properly trained personnel ensure optimal use of inspection tools and adherence to quality standards.

-

Using Statistical Process Control (SPC): This method monitors quality in real-time, identifying defects early in the production process.

Most Common Defects Found During PCBA Inspections

-

Soldering Issues: Cold joints, bridges, and excessive solder can cause functional failures.

-

Misalignment: Components placed incorrectly can result in electrical faults or failures.

-

Short Circuits: Unintended conductive paths often caused by solder bridges or damaged components.

-

Component Failures: Some components may fail due to manufacturing defects or incorrect specifications.

Frequently Asked Questions

Choosing the best method requires considering assembly complexity, production volume, budget, and quality requirements. For high-volume, complex PCBs, automated methods like AOI and ICT are recommended. Smaller batches or prototypes can be inspected with flying probes or visual checks.

Automated Optical Inspection (AOI) is an automated system that uses cameras to inspect PCBs for defects like misalignment and soldering errors. AOI is fast, accurate, and helps identify issues early in the production process, making it ideal for high-volume manufacturing.

To improve efficiency, invest in automated inspection technologies like AOI and ICT. Standardize inspection protocols, ensure proper team training, and consider Statistical Process Control (SPC) for monitoring quality during production.

Common defects include soldering issues (cold joints, solder bridges), misalignment of components, short circuits, and component failures. These defects can be detected using AOI and ICT, preventing costly production issues.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

👉 See how our Turnkey PCB Assembly can help »

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!