Quick Leads

Key Features to Look for in a High-Performance Gas Detector Sensor PCB

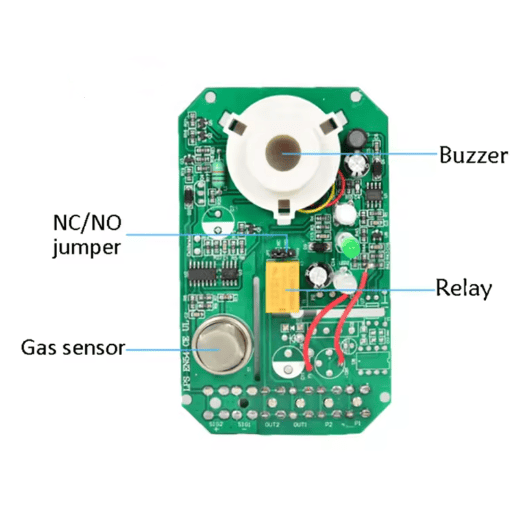

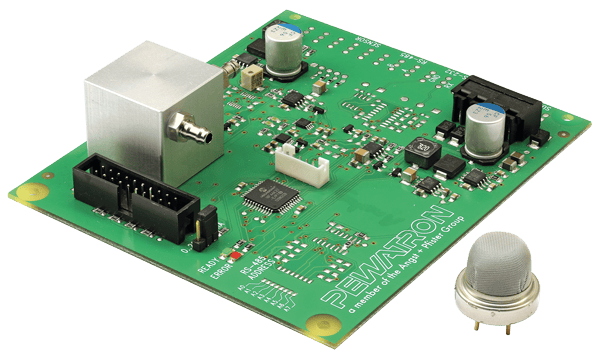

What Does a Gas Detector Sensor PCB Do?

Key Features of a High-Performance Gas Detector Sensor PCB

- 1.High SensitivityThe PCB should support sensors that are super sensitive and can detect even tiny amounts of bad gases. You want to find out when something is going wrong so you can stop it before it gets bad.

- 2.Fast Response Time

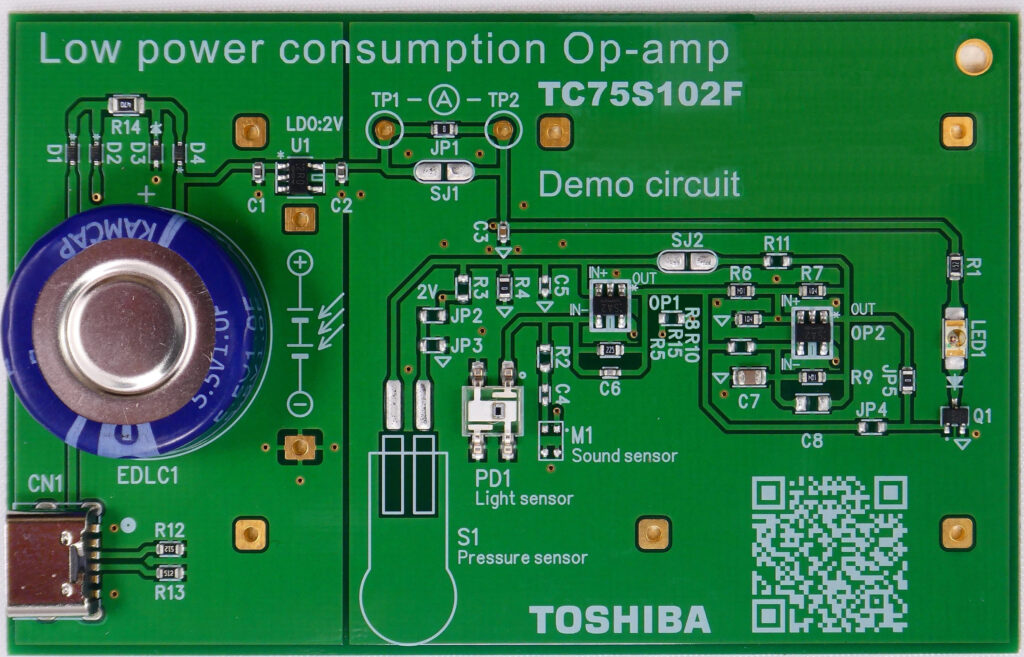

- 3.Low Power ConsumptionGas detectors are often used in remote or industrial environments. A PCB with low power consumption makes sure that your thing can work for a long time without you having to change the batteries all the time.

-

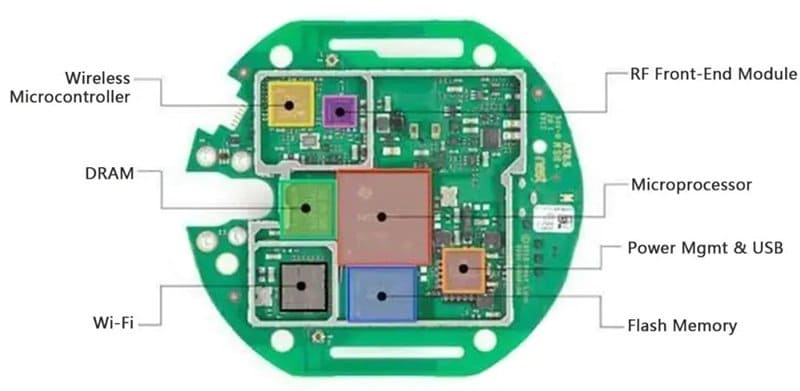

4.Compact SizeThe size of the PCB should be compact to fit within various gas detection devices. This is really important when you don’t have a lot of room, like in a portable detector.

-

5.Environmental ResistanceYour PCB needs to be able to take the environment such as humidity, temperature fluctuations, and contamination. If you put a coating on it and seal it up, your PCB will work even when things get bad.

- 6.Long LifespanThe longer your thing lasts, the less you have to mess with it and the less you have to pay for a new one. Look for PCBs that are made to last a long time so your gas detector will work for a long time.

- 7.Easy InstallationA high-performance PCB should be easy to put in different gas detectors. You should be able to tell what everything is and it should work with the other stuff you want to use.

- 8.Immunity to InterferenceYour PCB needs to be made so that it doesn’t get messed up by other electric stuff. That way, you can get the right numbers even when you’re in a place with a lot of machines.

Key Factors to Consider When Choosing a Gas Sensor PCB

- Sensor Life: The longer your sensor lasts, the less you have to mess with it and the less you have to pay for a new one.

- Sensitivity: Super sensitive sensors find out when bad gases are there.

- Size and Integration: A small design fits in a lot of different things.

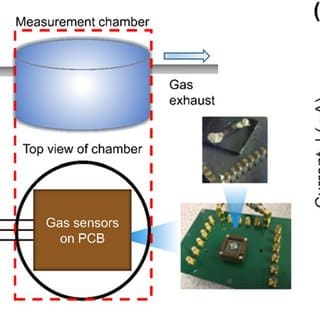

How Gas Detector Sensor PCBs Handle Humidity and Contamination Issues

- Protective Coatings: The PCB is often coated with protective materials that prevent moisture and contaminants from reaching sensitive electronic components.

- Sealed Components: Components like sensors and connectors are sealed to block out humidity and dirt, ensuring long-term reliability.

- Robust Design: In some cases, the PCB is designed to withstand extreme temperatures and high levels of humidity, making it suitable for industrial environments.

Real-World Examples of Gas Sensor PCB Applications

Conclusion: Making the Right Choice for Your Gas Detector Sensor PCB

Frequently Asked Questions (FAQs)

The key features include high sensitivity, fast response time, low power consumption, compact size, long lifespan, environmental resistance (to humidity and contamination), easy installation, and immunity to interference. These features make sure that your gas detector works right in a lot of different places.

Gas detector sensor PCBs are made to take the environment. They put a coating on them and seal them up so that water and dirt don’t mess them up. These things make sure that your PCB works for a long time, even when you’re in a place with a lot of machines.

You want sensors that are super sensitive and can find tiny amounts of bad gases. You want to find out when something is going wrong so you can stop it before it gets bad.

A good gas detector sensor PCB is made to last a long time. If you take care of it, it will work for a long time. That way, you don’t have to mess with it all the time, and you can trust it to work when you need it.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverRequest for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!