Unit Circuits

As one of China’s top Electronics Manufacturing Services (EMS) providers, Unit Circuits offers a complete range of PCB assembly services that take the hassle out of sourcing components or assembling your printed circuit boards.

Our skilled and experienced team can handle every part of the PCB assembly process for you—whether it’s sourcing the components, placing them on the board, or handling the soldering and testing. With decades of hands-on experience, we’re experts in bringing your designs to life exactly as you envisioned.

We pride ourselves on getting it right the first time, every time. Whether you need standard PCB assembly or our fast-turnaround service, we ensure quick delivery and your complete satisfaction.

Let’s take a closer look at what our service offers.

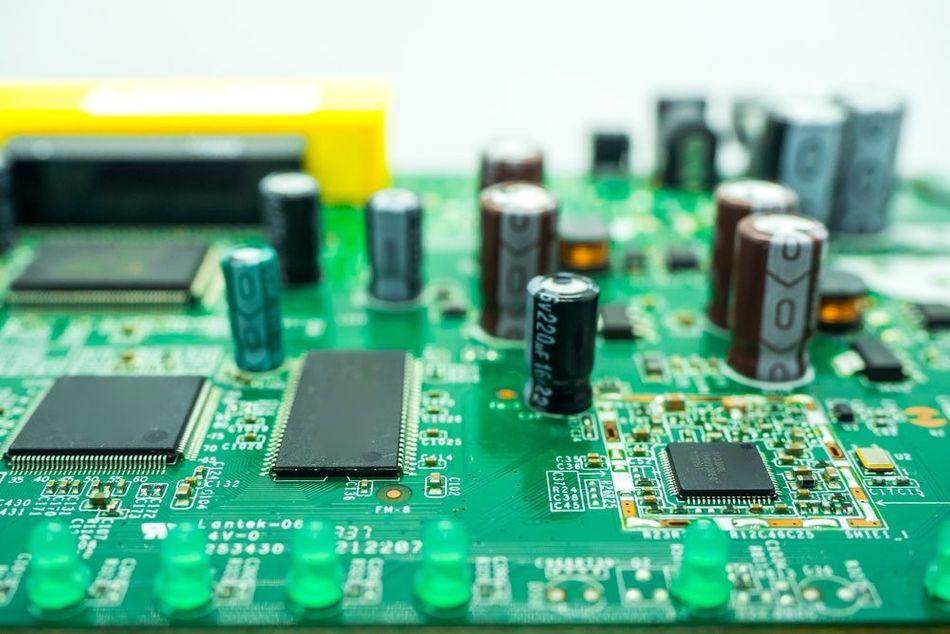

What does PCB assembly actually mean?

PCB assembly is the step that comes after designing and manufacturing a custom printed circuit board. Once the design is finalized based on the client’s needs, the manufacturer creates the blank PCB boards. The next step is to gather and attach all the necessary components—this is where the assembly process begins.

At this point, the board and its copper traces are ready, but until the required parts are securely soldered in place, the PCB is just a board with potential. To make it functional, every component needs to be carefully placed and properly connected.

If you want to learn more about PCB assembly or get detailed insights into the design and manufacturing stages, feel free to explore our other guides.

What skills and techniques does PCB assembly involve?

Once your components are sourced and ready, the next step is to mount them onto the PCB. There are two main methods for this: Surface Mount Technology (SMT) and Through-Hole Technology (THT).

Each approach has its own advantages depending on the specific project. No matter which method you choose, precise soldering is essential to securely and accurately attach your components. This can be done either by hand or using automated machines.

The goal is to create a printed circuit board that works reliably and efficiently for its intended purpose. Achieving this requires skilled craftsmanship, experience, quality tools, and close attention to detail—things we prioritize at Unit Circuits in every project.

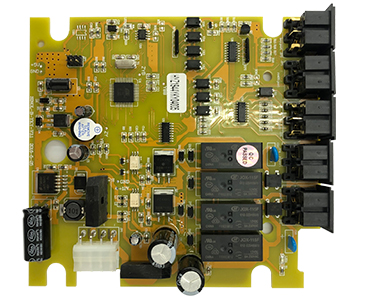

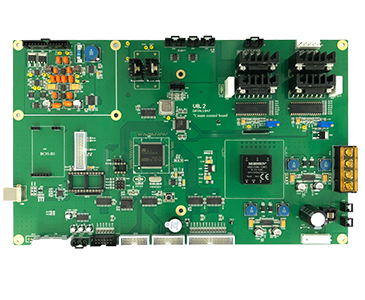

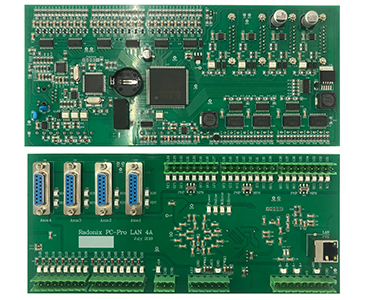

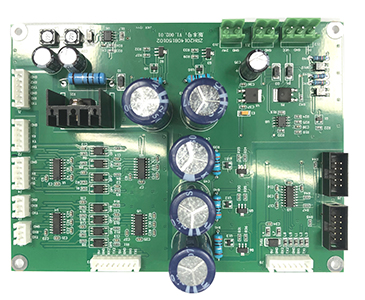

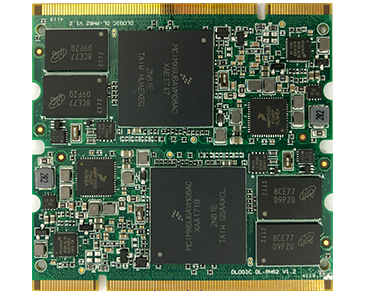

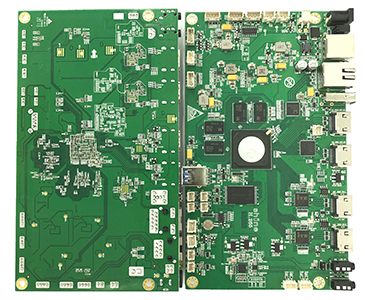

PCBA Products

What are the main differences between SMT and THT assembly?

Surface Mount Technology (SMT) involves soldering components directly onto the surface of the PCB. In contrast, Through-Hole Technology (THT) requires inserting the component leads—thin metal wires—through small holes in the PCB and soldering them on the opposite side.

SMT is often preferred when you need a faster, more cost-effective solution. It’s great for projects where space is limited because SMT components are typically smaller and can be placed closer together on the board. Using Pick and Place machines in SMT assembly can further speed up the process by accurately positioning components before soldering.

On the other hand, THT is ideal when a stronger physical bond is needed at the solder points, such as for connectors or components that will face more mechanical stress. Although THT assembly takes a bit longer due to extra steps in both design and manufacturing, it provides a more durable connection. THT components tend to be larger and slightly more expensive due to the need for those conductive “legs” that pass through the PCB.

Whether you choose SMT or THT, both methods can be done manually or with the help of automation, depending on your project’s needs.

If you need advice on which approach is best for your project, or if you’re ready to get started, feel free to reach out to our team at Unit Circuits. We’re here to help and can provide you with a fast, no-obligation quote.

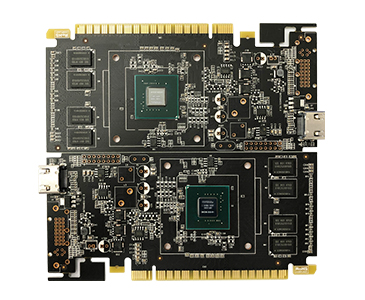

Your Trusted Partner for PCB Assembly Solutions

At Unit Circuits, we pride ourselves on our rich experience in providing top-notch circuit board assembly services. From PCB manufacturing and components procurement to PCBA and testing, we offer comprehensive solutions to meet your needs. Our team of PCB industry experts works closely with you to ensure fast turnaround times and the highest quality results. Contact us today to discover how Unit Circuits can take your PCBAs to the next level!

Capability

| Item | Description |

| Assembly Technologies | SMT, TH, Mixed PCBA, BGA |

| PCB Types | Rigid, Flexible, Rigid-Flex PCBs, MC PCBs, Ceramic PCBs, Rogers PCBs |

| Parts Procurement | Full Turnkey, Partial Turnkey, Consigned/kitted |

| Component Size | Smallest 01005, Micro BGA, Fine Pitch Parts |

| Production Capacity | 12 SMT lines, 6 DIP Production Lines, Produce 2.5 million pcs per day |

| Soldering Types | Reflow Soldering, Wave Soldering |

| Repair & Rework | Ball Grid Array replacement, IR rework |

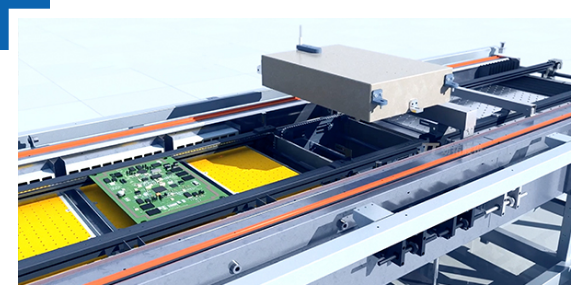

Assembly Process

Comprehensive, reliable, performance, validation, automated, functional testing for electronics.

Inspection Process

Pre-assembly, packaging, value, verification, station parts inspection process.

Initial, detailed, verification, quality, First Article Inspection ensures compliance.

Comprehensive, reliable, performance, validation, automated, functional testing for electronics.

Quality Control

Accurate Testing

Real-Time Tracking

FAQs about PCB Assembly

At Unit Circuits, we provide comprehensive PCB assembly services, including surface-mount technology (SMT), through-hole assembly, mixed technology PCB assembly, and complete turnkey solutions. Whether you need prototype assembly or full-scale production, we tailor our services to meet your specific requirements.

Quality is our top priority. We employ rigorous quality control measures throughout the assembly process. From initial inspection of components to final testing, we adhere to industry standards to guarantee reliable and high-performance PCB assemblies.

Absolutely. We specialize in customizable PCB assembly solutions to suit unique design specifications. Our team collaborates closely with you to understand your requirements and deliver tailored solutions that meet your exact needs.

We understand the importance of timely delivery. Our streamlined processes and efficient logistics enable us to offer fast turnaround times without compromising on quality. Whether your project requires expedited delivery or standard timelines, we ensure prompt and reliable service.

Yes, we provide comprehensive testing services to ensure the functionality and reliability of your PCB assemblies. Our testing capabilities include functional testing, in-circuit testing (ICT), and environmental testing, ensuring that your products meet stringent quality standards before shipment.

Getting a quote is easy. Simply contact us through our website or email us at sales@unitcircuits.com with your project specifications. Our team will promptly provide you with a detailed quote tailored to your requirements.

We cater to a diverse range of industries, including but not limited to electrical system design, electronic hardware manufacturing, prototyping, and intelligent machine development. Our adaptable services support various applications across different sectors.

Confidentiality is paramount to us. We uphold strict confidentiality agreements and implement robust security measures to safeguard your intellectual property and project details throughout the assembly process.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0