Quick Leads

Top 7 PCB Design Challenges and How to Overcome Them: Expert Solutions

Introduction

Ever wondered why your PCB designs aren’t performing as expected, even after hours of work? PCB design is a complex process, and even experienced designers face a number of challenges. Whether you’re dealing with signal integrity, thermal management, or manufacturing issues, understanding and overcoming these obstacles is key to creating high-performing, reliable circuit boards. In this article, we’ll dive into the top 7 PCB design challenges and provide expert solutions to help you navigate through them.

1. Signal Integrity Issues in PCB Design

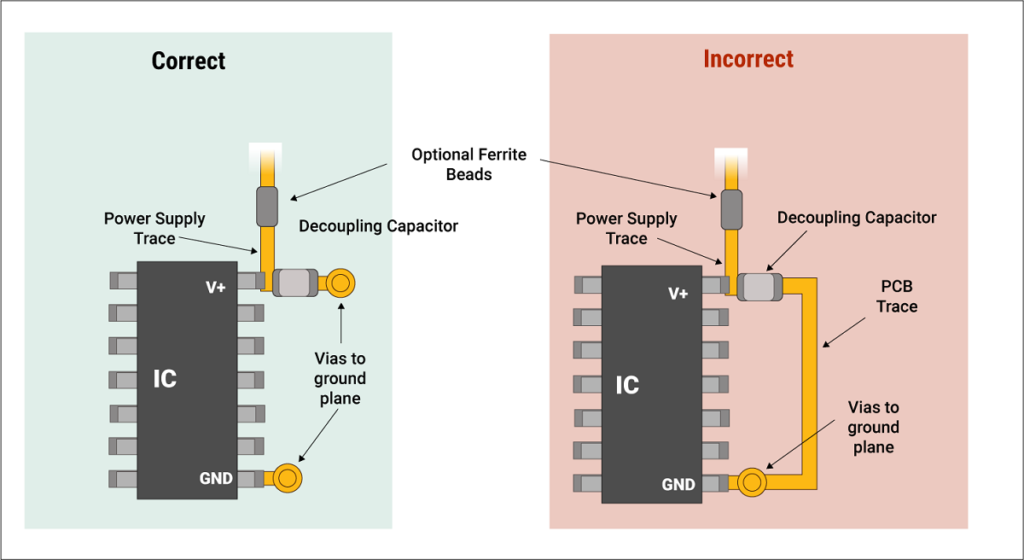

Signal integrity is one of the most critical aspects of PCB design. Problems such as crosstalk, reflections, and noise can lead to malfunctioning circuits, affecting the performance of your product.How to Overcome Signal Integrity Issues in PCB Design

- Optimize Trace Routing: Properly routing high-speed signals minimizes the chances of interference.

- Use Ground Planes: Implementing ground planes helps to reduce noise and maintain signal quality.

- Add Decoupling Capacitors: Place decoupling capacitors near power pins to smooth out voltage fluctuations and improve signal quality.

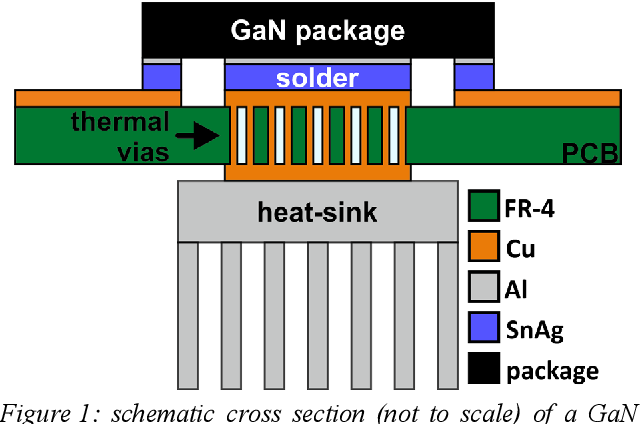

2. Thermal Management Challenges

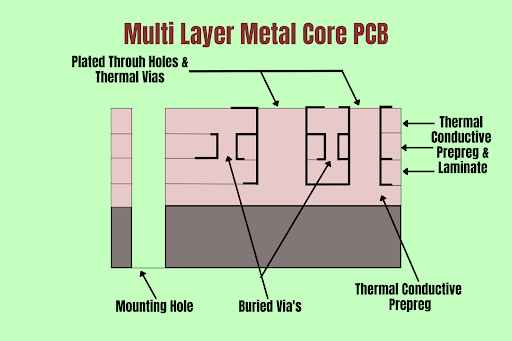

Managing heat is essential, especially in high-power circuits. Excessive heat can lead to component damage or failure, reducing the lifespan of your PCB and potentially causing system shutdowns.Best Practices for Thermal Management

- Use Heat Sinks: Attach heat sinks to components that generate significant heat to dissipate the excess temperature.

- Optimize Trace Width: Wider traces can dissipate heat more effectively.

- Incorporate Thermal Vias: Use thermal vias to transfer heat to the other side of the PCB or to a heat sink.

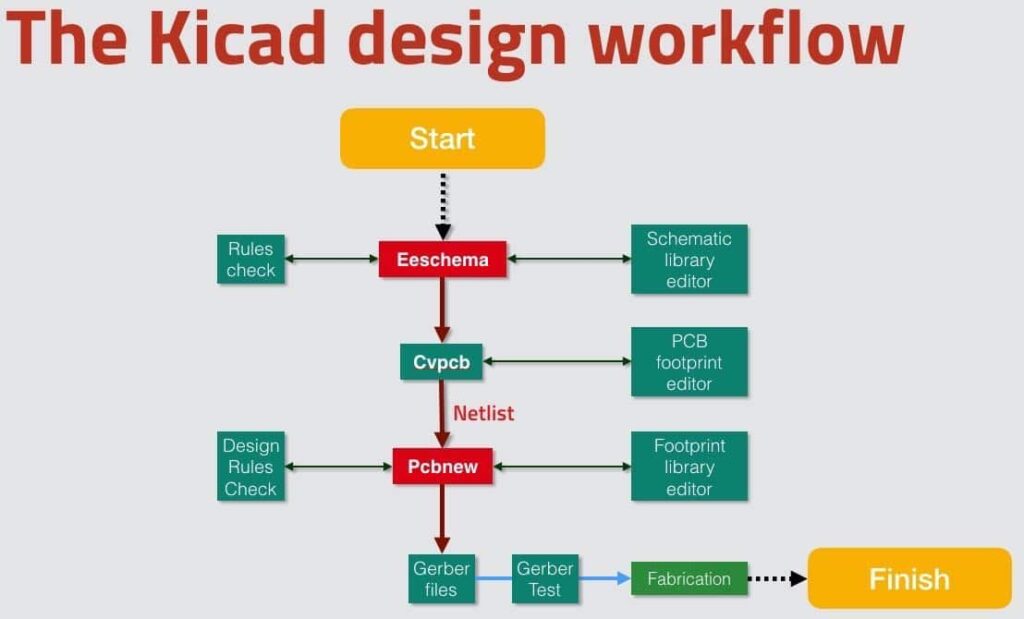

3. Design Rule Violations (DRC)

Design rule violations are common in the PCB design process. These violations occur when a design doesn’t comply with the minimum spacing and width requirements, often leading to manufacturing issues.How to Avoid Design Rule Violations

- Regular DRC (Design Rule Checks): Use automated tools to check for violations before finalizing the design.

- Optimize Grid Spacing: Ensure your components and traces follow proper spacing guidelines to avoid violations.

- Simplify Layout: Minimize the complexity of your PCB layout to reduce the chances of DRC issues.

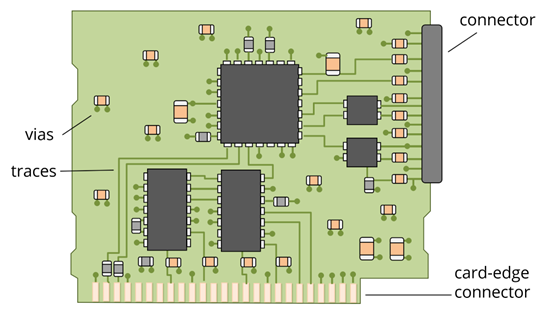

4. Component Selection and Placement

Choosing the right components for your PCB is essential to ensure performance, reliability, and cost-effectiveness. Incorrect component selection can lead to issues in performance and manufacturability.How to Optimize Component Selection and Placement

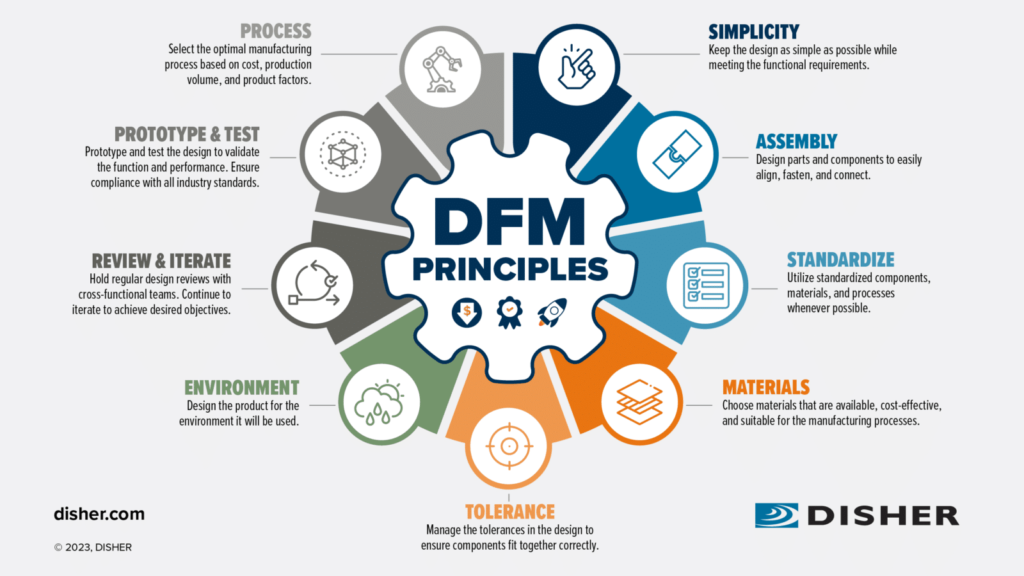

- Use DFM Tools: Utilize Design for Manufacturability (DFM) tools to evaluate the manufacturability of your design.

- Place Components Strategically: Proper placement ensures minimal signal interference and optimal power distribution.

5. High-Speed PCB Design Challenges

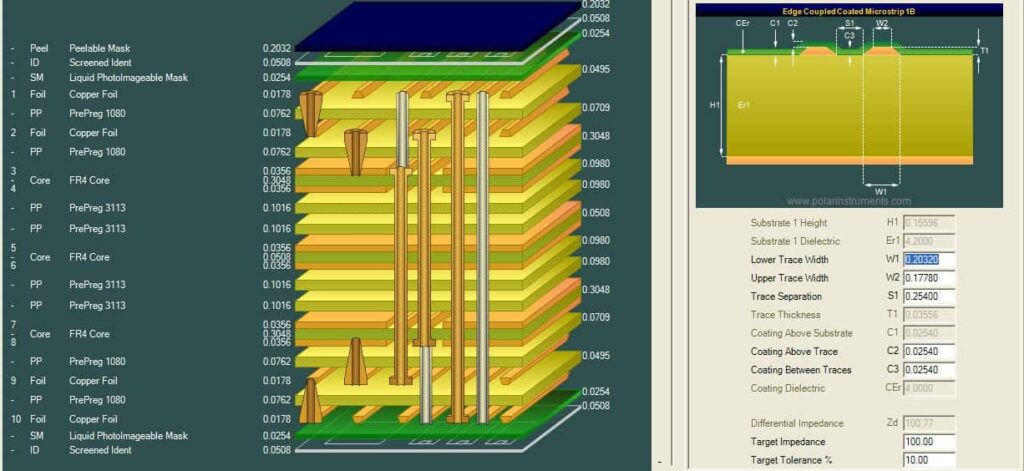

High-speed designs, such as those used in RF (Radio Frequency) or digital systems, require precise routing to maintain signal quality and integrity. High-frequency signals are particularly susceptible to noise and interference.How to Overcome High-Speed Design Challenges

- Use Controlled Impedance Routing: Ensure that traces are routed with controlled impedance to minimize reflection and signal loss.

- Minimize Trace Lengths: Keep the trace lengths as short as possible to reduce delay and signal degradation.

- Incorporate Proper Grounding: Proper grounding is essential in high-speed designs to maintain signal integrity.

6. Thermal Expansion and Material Choices

The choice of materials in PCB manufacturing plays a crucial role in preventing thermal expansion problems. Incompatible materials can cause the PCB to warp under heat, which can affect component connections.How to Manage Thermal Expansion

- Choose the Right Materials: Select materials with low coefficients of thermal expansion (CTE) to prevent warping.

- Test for Thermal Stress: Run simulations to check how materials behave under high temperatures.

7. Design for Manufacturability (DFM) Challenges

DFM ensures that the design can be easily manufactured without errors or additional costs. A failure to consider DFM can lead to costly revisions and delays during production.Best Practices for DFM

- Standardize Component Sizes: Using standard components helps ensure that parts are available and reduce manufacturing complexity.

- Ensure Fabrication Constraints: Make sure that all traces, holes, and vias meet fabrication constraints before sending the design for production.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

In the world of PCB design, challenges are inevitable, but they can be overcome with the right strategies and tools. By focusing on areas like signal integrity, thermal management, and DFM, you can create more reliable and efficient PCB designs. As you tackle these issues, remember that a well-designed PCB not only meets performance standards but is also cost-effective and manufacturable. Ready to take your PCB design to the next level? Contact us today for expert PCB assembly services, fast quotes, and high-quality solutions!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!