Quick Leads

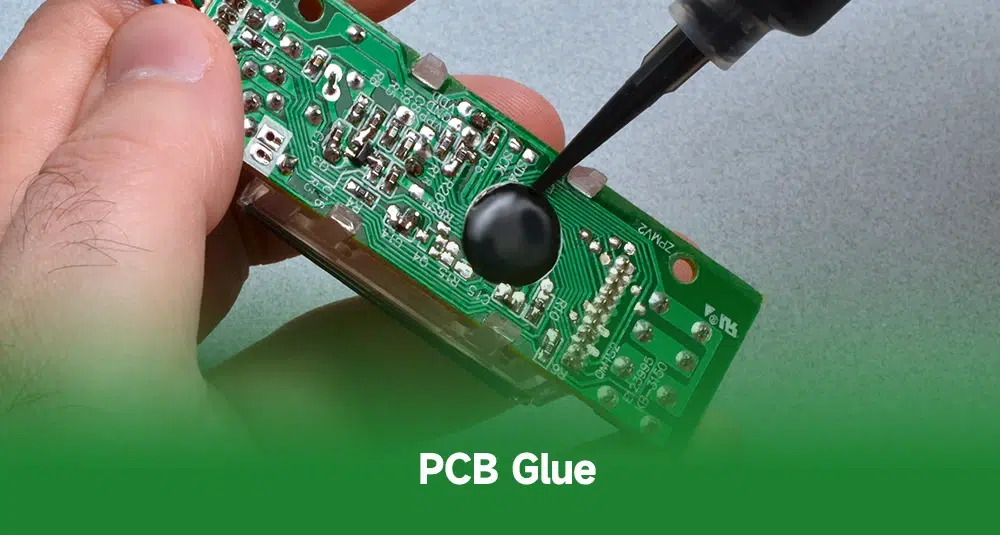

PCB Glue: Best Adhesion Practices for Reliable Component Assembly and Long-Lasting Performance

Adhesives, commonly referred to as “PCB glue,” play a pivotal role in printed circuit board (PCB) assembly. They keep parts stuck together, circuits safe, and devices working, even in tough places. Whether you’re working on industrial electronics or consumer gadgets, picking and using the right glue is key to making things that last and work.

This guide is going to give you a comprehensive look into the different types of PCB adhesives, their applications, best practices for reliable assembly, and actionable solutions to common challenges.

Why PCB Adhesion is Critical for Long-Term Reliability

Key Roles of Adhesives in PCB Assembly:

- Component Stability: Glue keeps your parts from moving around when you’re soldering them or when you’re shaking them.

- Environmental Protection: Glue keeps water, dirt, and other debris out of your parts, which is great if you’re using your stuff outside or in a factory.

- Thermal Management: Glue can take the heat, so your parts don’t fall off when things get hot.

- Electrical Insulation: Non-conductive adhesives prevent short circuits, ensuring safe and uninterrupted operation.

💡 Pro Tip: Look at where your thing is going to be and then pick a glue. For high-temperature or vibration-prone environments, opt for high-performance materials like epoxy or silicone.

Understanding PCB Adhesives

Not all adhesives are suitable for PCB assembly. How good a glue works depends on what it’s made of and how well it works with the board.

Key Properties to Evaluate:

- Bond Strength: High-strength adhesives ensure that components remain secure under mechanical stress.

- Thermal Resistance: For devices that get hot, like car or industrial electronics.

- Curing Time: Fast-drying glue is good for making a lot of things, while slow-drying glue lets you fix your mistakes.

- Flexibility: Silicone adhesives excel in environments with vibrations or frequent thermal expansion.

- Electrical Insulation: Prevents interference and ensures the safety of sensitive circuits.

💡 Pro Tip: Always test adhesives on a sample PCB to verify performance under real-world conditions.

Different Types of PCB Adhesives and When to Use Them

- Epoxy Adhesives

Epoxy glue is really strong, can take the heat, and doesn’t get messed up by chemicals.

- Advantages: Strong mechanical bonding, long lifespan, and resistance to extreme environments.

- Best For: Industrial control systems, high-performance computing devices.

- Example Use Case: Gluing parts in boards used in machines that get chemicals on them.

- Silicone Adhesives

- Advantages: High flexibility, moisture resistance, and thermal stability.

- Best For: Automotive electronics, outdoor devices.

- Example Use Case: Bonding components in an engine control module subjected to constant vibration.

- Non-Conductive Adhesives

These glues are made to stick parts together and keep electricity from going where it’s not supposed to go.

- Advantages: Quick curing, compatibility with sensitive components.

- Best For: Consumer electronics, wearables.

- Example Use Case: Securing connectors in a smartphone while maintaining electrical insulation.

- Contact Adhesives

Contact adhesives require application on both surfaces and are ideal for heavy-duty bonding.

- Advantages: High bonding strength, versatile application.

- Best For: Custom or specialized PCB assemblies.

- Example Use Case: Creating custom enclosures for high-precision PCB assemblies.

PCB Adhesion Best Practices for Reliable Assembly

- Surface Preparation

- Clean the surface with isopropyl alcohol (IPA) to remove dust, grease, and residues.

- Sand rough areas to enhance adhesive bonding.

- Ensure surfaces are dry and free of contaminants.

💡 Pro Tip: Use anti-static tools when you get ready to glue so you don’t blow up your parts.

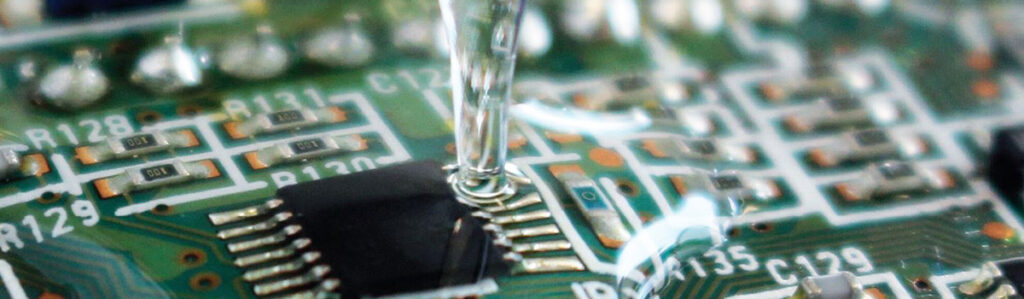

- Precision Application

- Use dispensing tools for accurate adhesive application.

- Avoid overapplication, which can lead to seepage into sensitive areas.

- Position components immediately after applying the adhesive.

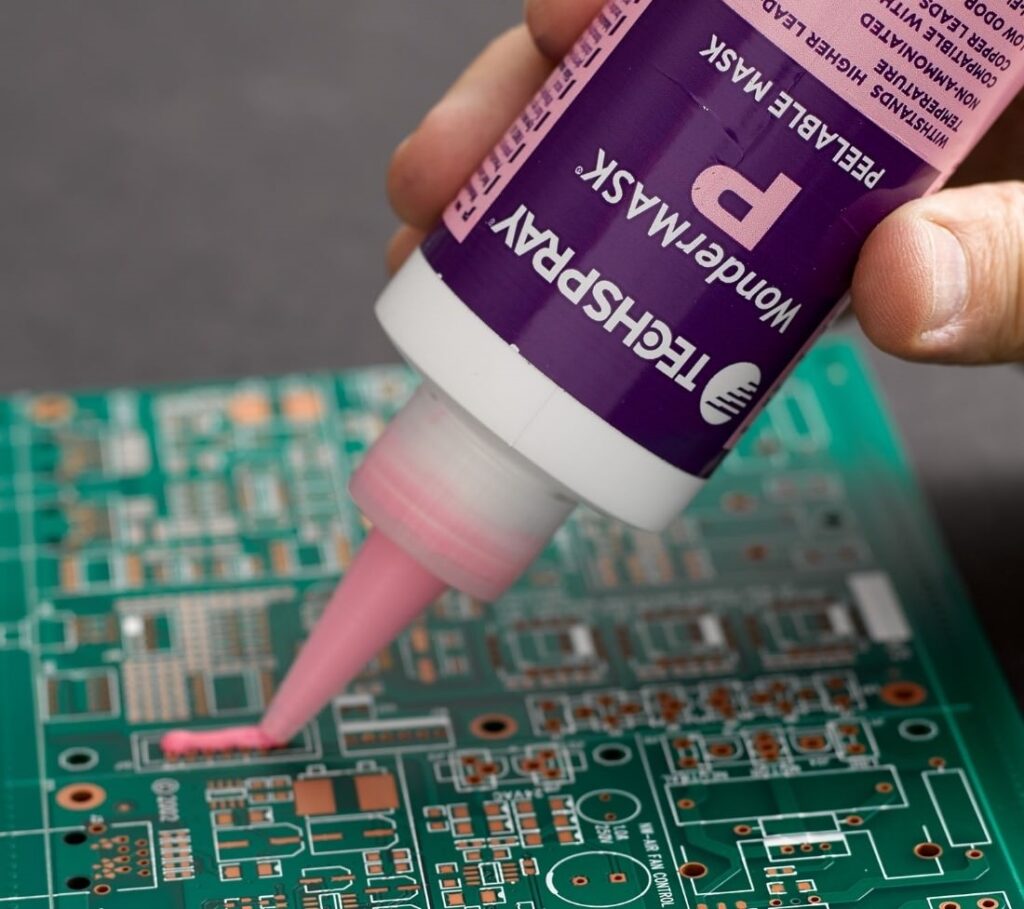

- Curing Process

- Follow the manufacturer’s curing guidelines for time and temperature.

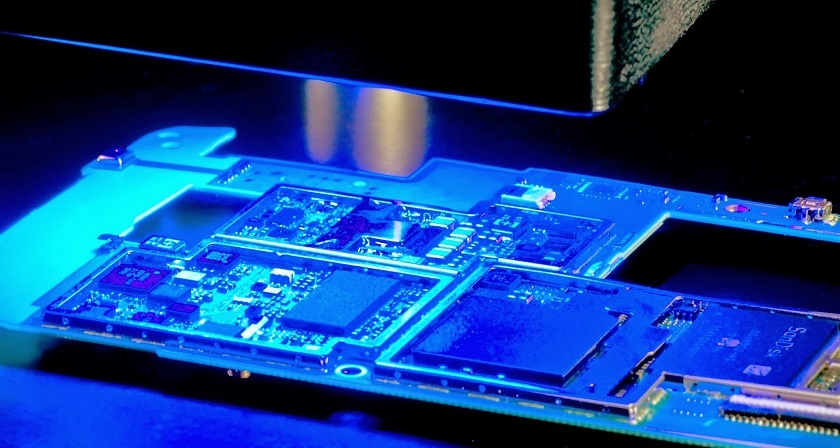

- Use UV-curable adhesives for faster assembly lines.

- Verify adhesive bonds through mechanical testing after curing.

- Post-Application Testing

- Conduct visual inspections for uniform adhesive coverage.

- Perform mechanical tests to ensure that bonds can withstand operational stress.

Common Industry Challenges and Solutions

- High-Vibration Environments

- Challenge: Components may detach due to repeated vibrations.

- Solution: Use silicone adhesives for their flexibility and vibration-absorbing properties.

- Extreme Temperatures

- Challenge: Adhesives may degrade or lose bond strength.

- Solution: Use epoxy adhesives designed for high-temperature resistance.

- Component Misalignment

- Challenge: Adhesive curing before proper alignment.

- Solution: Opt for slow-curing adhesives for more precise adjustments during assembly.

Real-World Use Cases of PCB Glue

Case Study 1: Industrial Control Boards

A company used glue to hold stuff together on a circuit board that got hot. This solution significantly reduced component detachment issues during thermal cycling.

Case Study 2: Automotive Electronics

An automotive supplier adopted silicone adhesives for PCBs in engine control modules. The glue was so good it could take the heat and the cold and still hold.

Case Study 3: Consumer Electronics

A manufacturer used epoxy to glue parts in industrial control boards that got hot. This approach minimized short circuits and enhanced device longevity.

Frequently Asked Questions (FAQs)

To avoid over-applying or leaking, use precision dispensing tools like syringes or automated dispensers. Apply the glue sparingly and in a controlled manner. It’s important to position the components immediately after applying the adhesive to keep it from drying in the wrong places.

Yes, both epoxy and silicone adhesives are designed to offer moisture resistance. These adhesives keep moisture out of the board, which can cause corrosion and malfunction.

Choose the right PCB glue based on temperature resistance, flexibility, curing time, and whether you need electrical insulation. Use epoxy for high-temperature environments and silicone for applications that experience vibrations.

Yes, specific adhesives like epoxy are designed to withstand extreme temperatures. They have a high thermal resistance, which makes them good for things like cars and industrial control systems.

To ensure a strong bond, proper surface preparation is crucial. Clean the PCB with isopropyl alcohol, apply the adhesive carefully using dispensing tools, and follow the manufacturer’s curing instructions to get the best bond strength.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Glue is the stuff that keeps your parts stuck to your board, even when things get tough. Pick the right glue, do it right, and you’ll be good to go.

🔧 Looking for expert PCB assembly services? Call Unit Circuits today for fast, reliable, and cheap solutions that fit your needs.

Key Takeaways:

Importance of Adhesives: PCB adhesives are essential for ensuring component stability, environmental protection, thermal management, and electrical insulation in electronic devices.

Choosing the Right Adhesive: The type of adhesive (epoxy, silicone, non-conductive, or contact) should be selected based on the device’s environment and performance requirements.

Best Practices for Application: Proper surface preparation, precision in adhesive application, and following curing guidelines are crucial for ensuring strong and lasting bonds.

Challenges and Solutions: Common PCB assembly challenges, such as vibrations, extreme temperatures, and misalignment, can be addressed by selecting the right adhesive and application method.

Real-World Use Cases: Adhesives, when chosen and applied correctly, improve the performance and longevity of PCB assemblies in industries like automotive, industrial control, and consumer electronics.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!