Quick Leads

PCB Prototyping: Everything You Need to Know Before Starting Your Project

PCB prototyping is a crucial step in the electronic design process. It allows engineers and designers to test their printed circuit board (PCB) designs before mass production. But why is PCB prototyping so important, and how can it improve your product development? In this comprehensive guide, we’ll cover everything you need to know about PCB prototyping, from the basics to advanced techniques.

What is PCB Prototyping?

PCB prototyping is when you make a preliminary version of your PCB design to test it out before you make it for real. It allows engineers to identify and fix design flaws, ensuring that the final product will function as intended. Prototypes help you avoid making expensive mistakes in the mass manufacturing phase by testing the electrical and mechanical performance of the board.

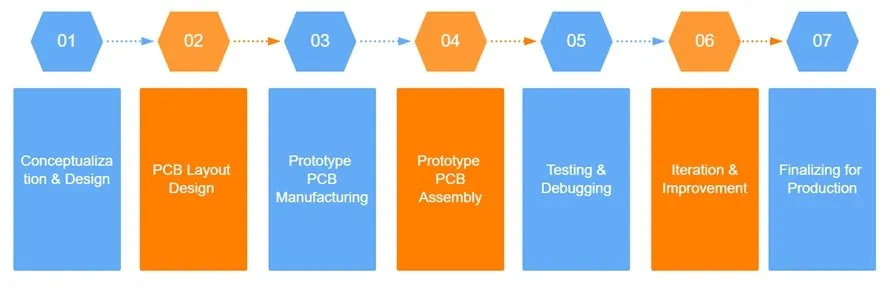

PCB Prototyping Steps: A Simple Guide to Getting Started

Creating a PCB prototype involves several key steps. Here’s a quick breakdown of the PCB prototyping process:

Design the Schematic: This is your circuit blueprint, outlining all components and their connections.

Create the PCB Layout: Place components and route traces, ensuring proper electrical flow.

Generate Manufacturing Files: Create Gerber files and bill of materials (BOM) for fabrication.

Select Prototyping Method: Choose between subtractive, additive, or 3D printing methods.

Manufacture the PCB: Fabricate the PCB using the chosen prototyping method.

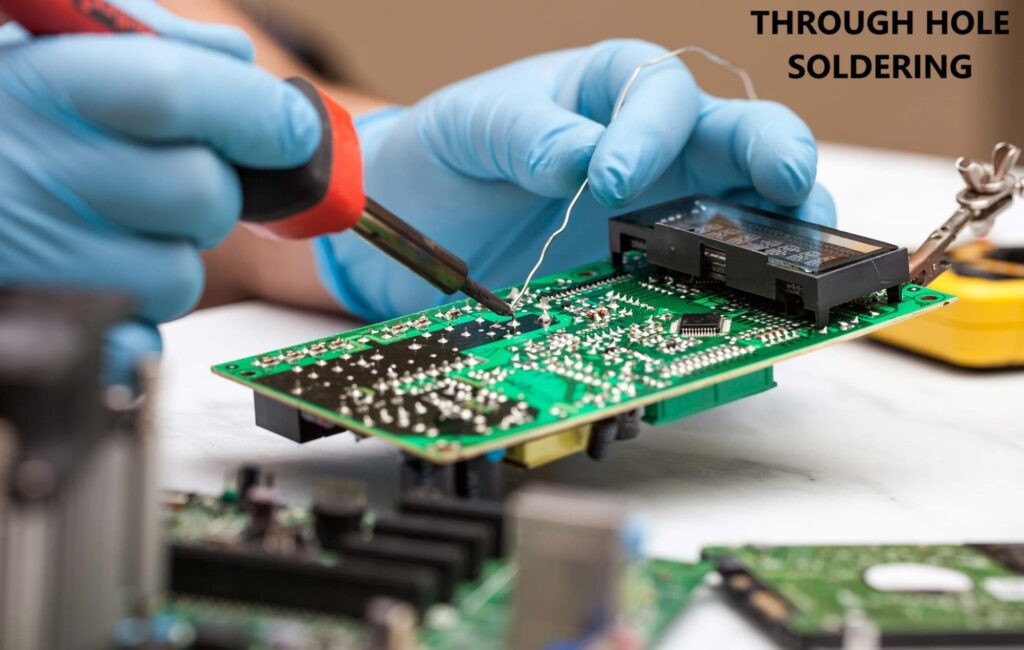

Solder Components: Attach components to the board.

Test the Prototype: Perform functional testing to validate your design.

Each of these steps requires careful attention to detail to ensure the PCB prototype is both functional and manufacturable.

Choosing the Right PCB Prototyping Method

For fast-turn PCB prototyping, a well-prepared BOM is just as important as Gerber files.

There are several methods for creating a PCB prototype. The best method depends on factors like design complexity, time, and budget. Here’s a quick guide to some of the most common PCB prototyping methods:

-

Subtractive Method: The most common approach, where copper is etched away to create traces.

-

Additive Method: Copper is added to the PCB surface, useful for simple designs and rapid prototyping.

-

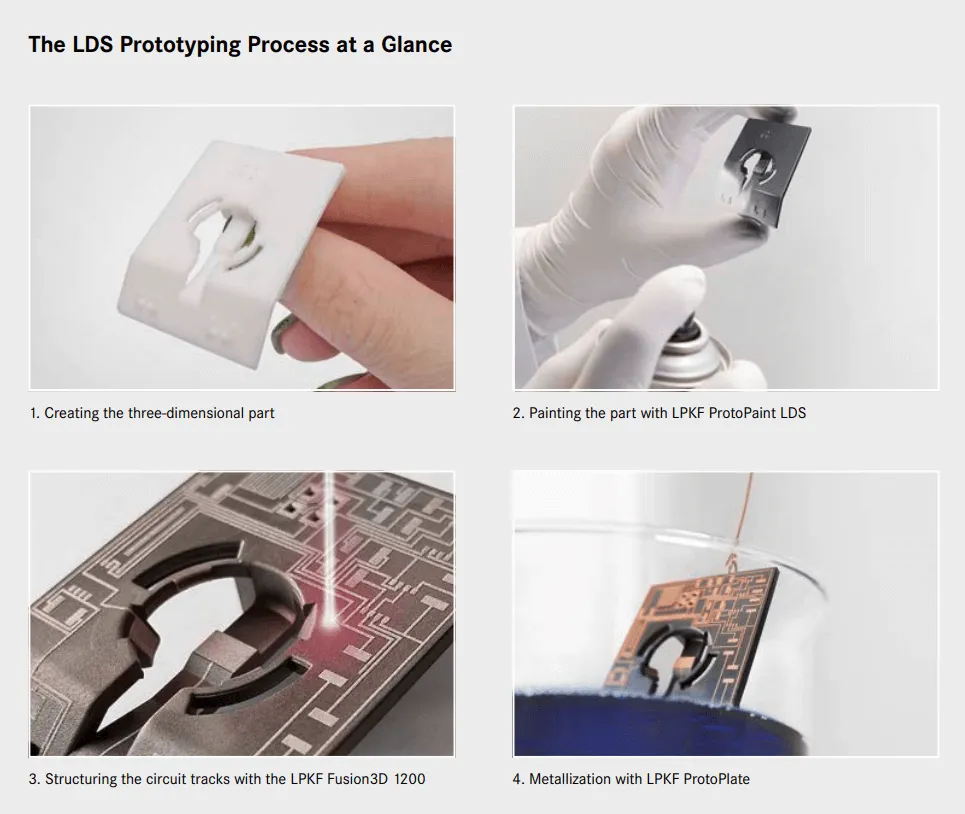

3D Printing: A modern technique, ideal for quick testing of simple designs or more complex components.

Each method has its pros and cons, so it’s important to select the one that fits your project’s needs. For rapid prototyping, additive PCB prototyping or 3D printing might be ideal, while subtractive methods are better for more detailed, production-ready prototypes.

Common Challenges in PCB Prototyping and How to Overcome Them

While PCB prototyping offers valuable insights, it also comes with its challenges. Below are some common issues and practical solutions:

-

Component Placement Errors: Incorrect placement can lead to assembly difficulties. Solution: Use CAD tools to simulate and verify component placement before manufacturing.

-

Signal Integrity Issues: Poor layout can cause electrical noise. Solution: Optimize trace routing and minimize interference with proper PCB design practices.

-

Cost of Prototyping: Prototyping can be expensive, especially for complex designs. Solution: Consider rapid prototyping services or shared prototyping options to save costs.

By understanding these challenges and using the right tools, you can avoid costly mistakes during the prototyping process.

Key Tools for PCB Prototyping

Several tools can help streamline the PCB prototyping process. Below are some commonly used tools:

-

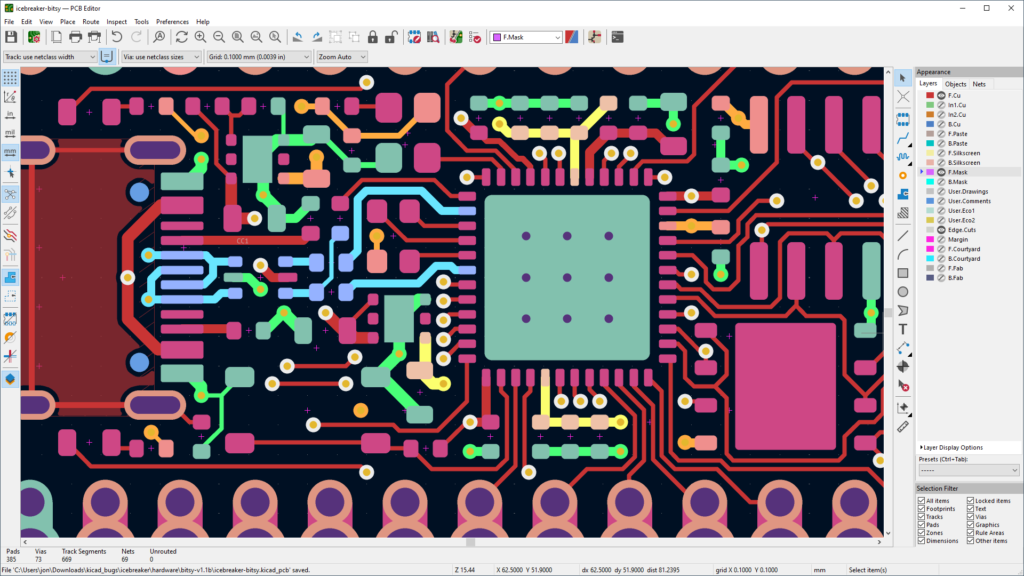

KiCad: A powerful, free, open-source tool for PCB design and prototyping. It helps you create detailed designs and simulate layouts.

-

CNC Milling Machines: These are used for PCB fabrication, drilling holes, and cutting traces.

-

3D Printers: Useful for prototyping complex designs quickly, especially when traditional methods aren’t feasible.

These tools, when combined with good design practices, can make your prototyping process more efficient and cost-effective.

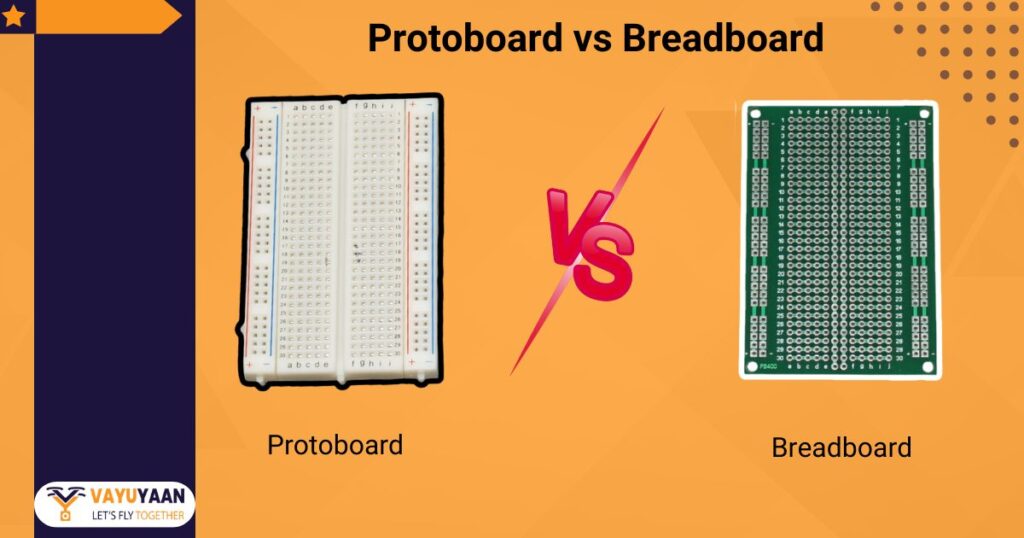

Perfboard vs. PCB Prototyping: Which Is Right for Your Project?

Many designers wonder whether to use perfboard (a perforated board) or a true PCB prototype. While perfboards are great for basic, low-complexity prototypes, they don’t have the precision and reliability of real PCB prototypes. Here’s how they compare:

-

Perfboard: Great for quick, low-cost prototypes but not ideal for complex designs.

-

PCB Prototyping: Offers higher reliability, especially for intricate or high-volume designs.

If your design requires high precision or is headed for mass production, a PCB prototype is your best bet.

Is KiCad the Best Tool for PCB Prototyping?

KiCad is an excellent, free tool for PCB prototyping, especially for startups and hobbyists. It offers powerful features like:

-

Schematic Capture: Easily design and modify electrical circuits.

-

PCB Layout: Route traces and place components accurately.

-

Simulation Tools: Verify electrical functionality before prototyping.

KiCad is a great choice for beginners and experienced designers who need a reliable, cost-effective tool for PCB design and prototyping.

PCB Prototyping Machines: What You Need to Know

To create a PCB prototype, you’ll need the right machines and equipment. Here’s an overview of common PCB prototyping machines:

-

CNC Milling Machines: These machines can precisely cut and drill PCBs, making them ideal for creating professional prototypes.

-

Laser Machines: Used for fine etching and cutting, these are great for high-precision designs.

-

3D Printers: Useful for rapid prototyping, especially for quick testing or smaller runs.

Investing in the right prototyping machine can significantly speed up your design process and improve the quality of your prototypes.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

PCB prototyping is a must-do for any electronics design, helping you catch mistakes early and make sure your design works like it’s supposed to. By following the right steps, picking the right prototyping methods, and using powerful tools like KiCad, you can make high-quality prototypes that meet your design specs. Whether you’re an engineer, entrepreneur, or product designer, understanding the prototyping process will give you the confidence to bring your products to life.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!