Quick Leads

Top 10 Applications for Printed Circuit Board Assembly

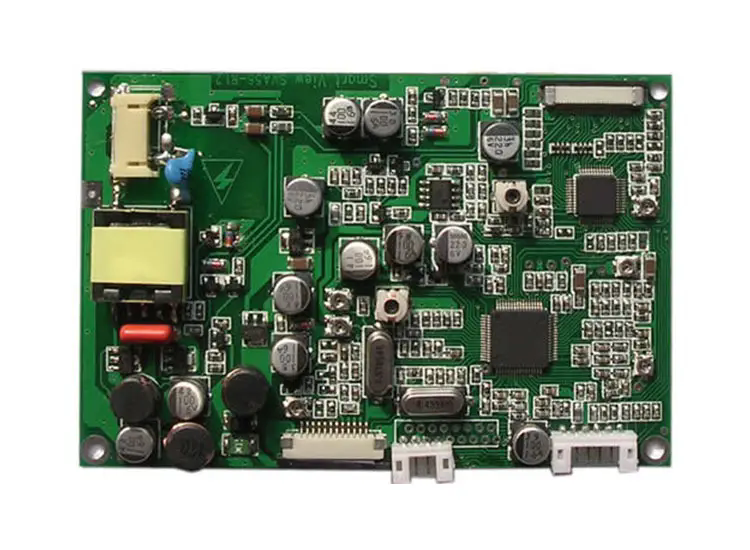

PCBA is the process of soldering electronic components onto a bare board, turning it into a working circuit. It’s the foundation of modern electronics, which power devices in every industry. Knowing where PCBA is used most often shows how important it is to innovation and technology.

PCBA is a big deal in industries like medical devices, automotive systems, consumer electronics, and aerospace technologies.The process involves putting components in the right place, soldering them, and testing them to make sure each board is good enough.

This is important because complex systems, like medical equipment and advanced automotive safety features, need to work right. As technology gets better, people want better PCBA, so it’s important to make good electronic products.

Let’s look at the top 10 places where PCBA is a must-have. These are the industries where you need good PCBA to make good electronic systems.

1. Medical Devices

PCBA is really important in medicine. You have to be really careful and make sure everything works right. Things like pacemakers, MRI machines, and patient monitors all need good PCBA to work right.

When you put the parts on the board, you have to be really careful to do it right so nothing goes wrong.

Example: When you put the parts on the board for pacemakers, you have to be really careful to do it right so nothing goes wrong. You have to make sure all the connections are good and that the pacemaker works all the time.

2. LEDs (Light Emitting Diodes)

PCBA is also really important in LEDs. You have to be really careful and make sure everything works right. You have to put the parts on the board in the right place and solder them right so the LEDs work good.

Example: When you put the parts on the board for LEDs, you have to be really careful to do it right so nothing goes wrong. You have to put the parts on the board in the right place and solder them right so the LEDs work good.

3. Consumer Electronics

PCBA is a big deal in consumer electronics. You have to be really careful and make sure everything works right. Things like smartphones, laptops, and video game systems all need good PCBA to work right.

When you put the parts on the board, you have to be really careful to do it right so nothing goes wrong.

Example: When you put the parts on the board for smartphones, you have to be really careful to do it right so nothing goes wrong.

You have to make sure all the parts are in the right place and that the phone works good.

4. Industrial Equipment

PCBA is really important in industry. You have to be really careful and make sure everything works right.

Industrial equipment has to work in really tough places, like hot, wet, or shaky places. When you put the parts on the board, you have to be really careful to do it right so nothing goes wrong.

Example: When you put the parts on the board for industrial robots, you have to be really careful to do it right so nothing goes wrong. You have to make sure all the connections are good and that the robot works all the time.

5. Automotive Components

PCBA is also really important in cars. You have to be really careful and make sure everything works right. Things like engine computers, radios, and safety features all need good PCBA to work right.

When you put the parts on the board, you have to be really careful to do it right so nothing goes wrong.

Example: When you put the parts on the board for ADAS, you have to be really careful to do it right so nothing goes wrong. You have to make sure all the connections are good and that the ADAS works all the time.

6. Aerospace Components

PCBA is really important in aerospace. You have to be really careful and make sure everything works right. Things like satellites and rockets all need good PCBA to work right. When you put the parts on the board, you have to be really careful to do it right so nothing goes wrong.

Example: When you put the parts on the board for avionics, you have to be really careful to do it right so nothing goes wrong. You have to make sure all the connections are good and that the avionics work all the time.

7. Maritime Applications

When you put the parts on the board for maritime, you have to be really careful to do it right so nothing goes wrong. You have to make sure all the connections are good and that the maritime stuff works all the time.

Example: In marine navigation systems, you need to make sure your stuff is sealed up and protected from saltwater. This is important because you want your stuff to keep working, especially when you’re out in the middle of the ocean.

8. Safety and Security Equipment

Safety and security equipment like fire alarms, security cameras, and intrusion detection systems rely on the reliability of their circuit boards.

In these applications, you need to make sure your stuff keeps working all the time and does what it’s supposed to do when it’s supposed to do it.

Example: When you put stuff together in fire alarms, you need to make sure they go off when they’re supposed to. If you mess up, the fire alarm might not go off when it’s supposed to, and that could be really bad.

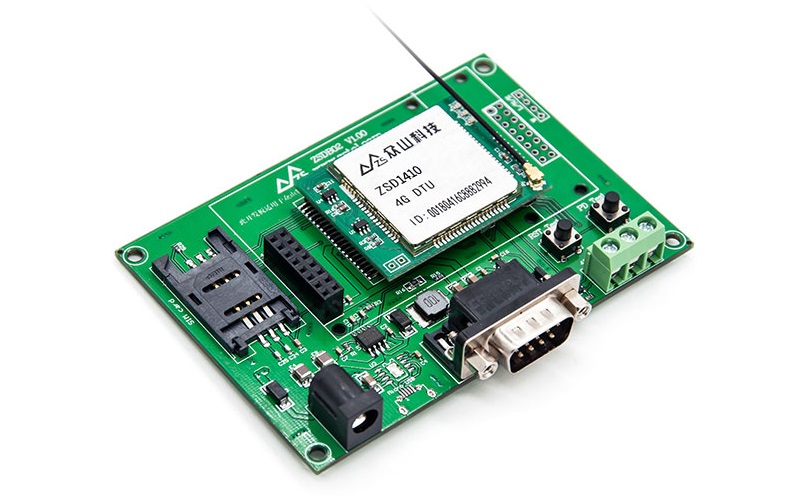

9. 5G Infrastructure and Smart Connectivity

The deployment of 5G networks and smart stuff has made it so we need faster circuit boards. These applications need circuit boards that can handle high frequencies and move data really fast.

When you put your stuff together, you need to put your stuff in the right place and make sure your connections are as fast as they can be.

Example: When you put together 5G antennas and radios, you need to pay attention to what you’re doing. You need to be really careful when you put your stuff together so you can move data really fast.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliver10. Defense and Military Equipment

In defense and military stuff, you need to make sure your stuff works all the time. These applications are in really tough places with really hot and cold temperatures, stuff that shakes, and stuff that moves.

When you put your stuff together, you need to make sure your stuff can handle all that stuff and keep working.

Example: When you put together military circuit boards, you need to make sure your stuff can handle really hot and really cold temperatures and stuff that shakes.

You need to make sure your stuff keeps working when you take it outside. You need to test your stuff to make sure it’s going to work when you put it in the field.

Summary

Putting stuff together on circuit boards is the foundation of modern electronics. It’s important in everything from medical stuff to military stuff. As electronics get more complicated, it’s more important to put your stuff together right.

If you understand how to put stuff together on circuit boards, you can design and build better stuff in today’s world.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!