Quick Leads

Tips for Reflow Soldering of SMT: Avoid Mistakes and Master the Process

Reflow Soldering in SMT: Overview

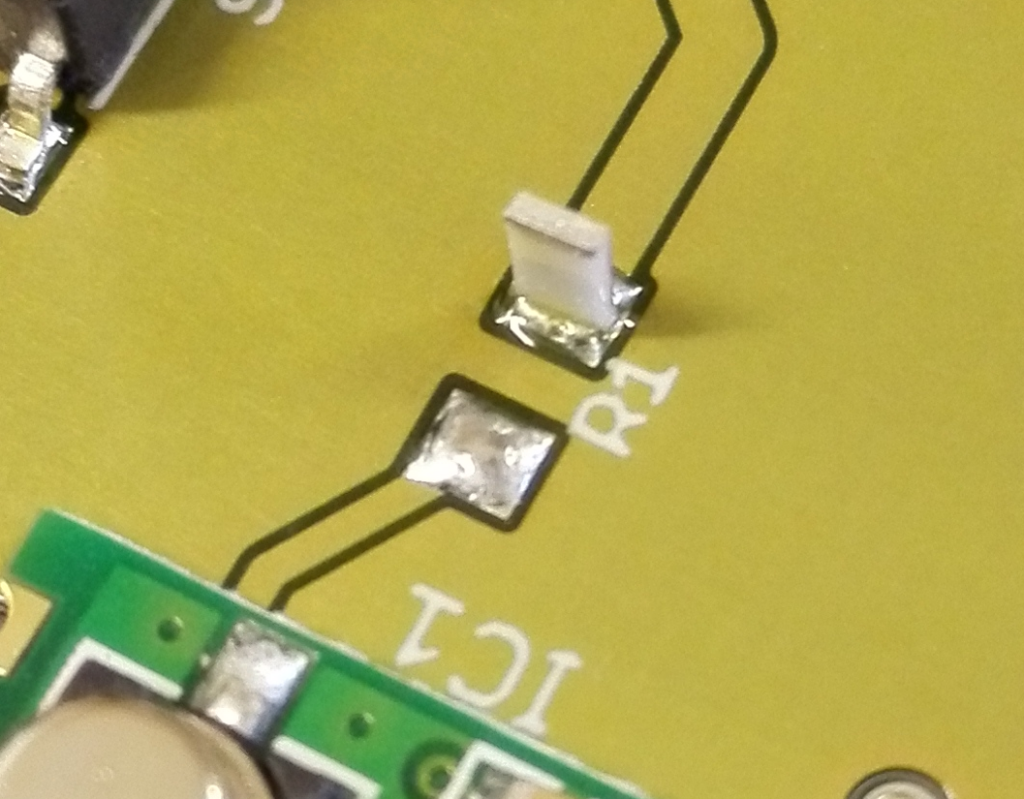

Reflow soldering is a process used in Surface Mount Technology (SMT) to attach components to a printed circuit board (PCB). It uses heat to melt solder paste, creating strong connections.

This is critical for making reliable, high-quality joints in PCB assemblies. It’s something that both professionals and hobbyists need to understand.

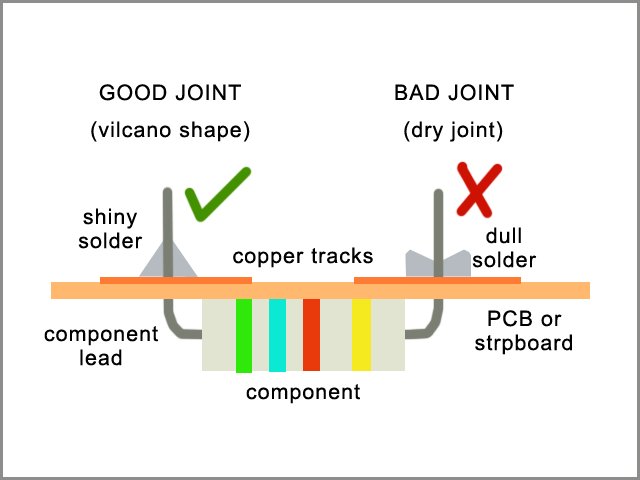

Reflow soldering is where you melt solder paste to connect SMT components to a PCB. The key things are keeping the right temperature, using good flux, and timing. Avoid tombstoning and solder bridges for a smooth process. The ideal reflow temperature is 240°C to 250°C for lead-free solder. This range makes sure the components and the PCB are solidly bonded.

Understanding these basics is just the beginning. Let’s dive into each step, avoid common mistakes, and learn best practices for success.

What is Reflow Soldering in SMT?

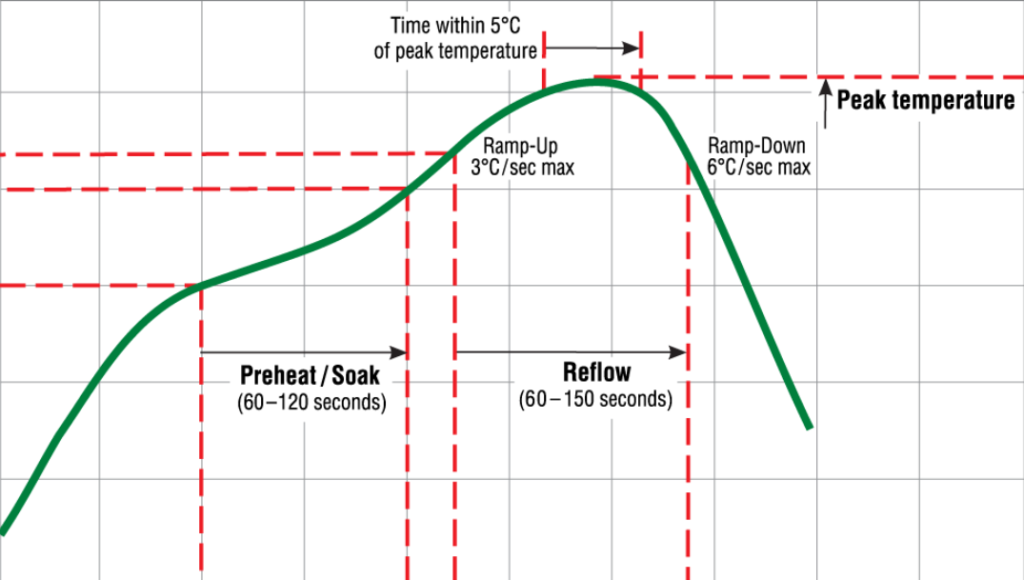

Reflow soldering is where you attach SMT components to a PCB by melting solder paste. It has four stages: preheat, soak, reflow, and cooling. This method is critical in high-volume electronics production because it’s accurate and efficient.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Step-by-Step Guide to Optimize Reflow Soldering in SMT

Follow these steps for consistent reflow soldering:

- 1.Preheat Stage: Gradually warm up the PCB and components. This prevents thermal shock. Aim for temperatures between 150°C and 180°C. Use a ramp-up rate of 0.5°C to 1°C per second.

- 2.Soak Stage: Distribute heat evenly and activate flux. Hold the temperature at 180°C to 200°C for 60 to 120 seconds.

- 3.Reflow Stage: Get up to a peak temperature of 240°C to 250°C. This melts the solder paste and makes strong connections.

- 4.Cooling Stage: Cool at 2 to 4°C per second. This hardens the solder joints and prevents defects like cracks.

Why Flux Quality Matters in Reflow Soldering

Flux is super important in SMT soldering. It removes surface oxidation, helps the solder stick, and makes sure the solder flows well. If you don’t have good flux, the solder might not bond right, and you’ll have weak joints.

How to Create an Optimal Reflow Profile for SMT

A good reflow profile leads to high-quality solder joints. Follow these tips:

- Ramp-Up Rate: Increase temperature gradually at 0.5°C to 1°C per second.

- Soak Zone: Even out the heat to prepare the solder paste.

- Peak Temperature: Keep between 240°C and 250°C for lead-free solder.

- Cooling Rate: Cool at 2-4°C per second to ensure strong joints.

Common Reflow Soldering Mistakes and How to Avoid Them

Here are common mistakes and how to prevent them:

- Mistake: Tombstoning

- Cause: Uneven heating during reflow.

- Solution: Apply solder paste evenly and adjust the heating profile.

- Mistake: Solder Bridges

- Cause: Excess solder connects adjacent pads.

- Solution: Use the right stencil thickness and precise paste application.

- Mistake: Component Misalignment

- Cause: Incorrect paste application or vibration.

- Solution: Use alignment marks and apply paste evenly.

Quick Guide: Optimal Reflow Temperature for Lead-Free Solder

For lead-free solder, use this temperature guide:

- Melting Points: 179°C to 188°C.

- Flux Activation: Starts at 200°C.

- Minimum Peak Temperature: 205°C to 210°C.

- Maximum Peak Temperature: 240°C to 250°C.

Reflow Soldering Tips for Beginners: Can It Be Done at Home?

Yes, you can do reflow soldering at home with the right tools:

- Use a thermocouple to monitor temperature.

- Practice on old boards to improve your technique.

- Ensure proper ventilation to avoid fumes.

- A basic reflow oven can achieve professional results.

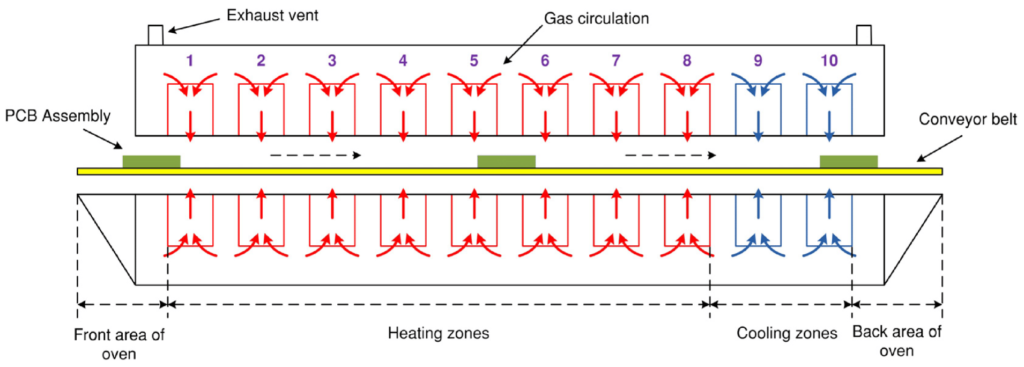

Choosing the Right Reflow Soldering Machine

When choosing a reflow soldering machine, consider:

- Batch Size: Small batch ovens are great for hobbyists. Conveyor systems are better for big production.

- Temperature Control: Precise control ensures accuracy.

- Budget: Compare features and prices for the best fit.

Machine Type | Best For | Key Features |

Batch Ovens | Hobbyists, small runs | Manual controls, affordable |

Conveyor Ovens | Mass production | Precise temperature control, high output |

Infrared Ovens | DIY setups, quick fixes | Portable, easy setup |

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary

Reflow soldering is easier when you know what you’re doing. Focus on temperature profiles, use good stuff, and avoid common mistakes. These steps help you make good solder joints. Keep practicing, be patient, and get better at SMT reflow soldering.

Need help with your SMT assembly process? Check out our guide on choosing the best solder paste.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!