Rigid-Flex PCB Assembly

High-Quality Rigid-flex PCB Assembly Services Since 2017

- Single & Double-Sided SMT/TH Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 components, BGA, micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

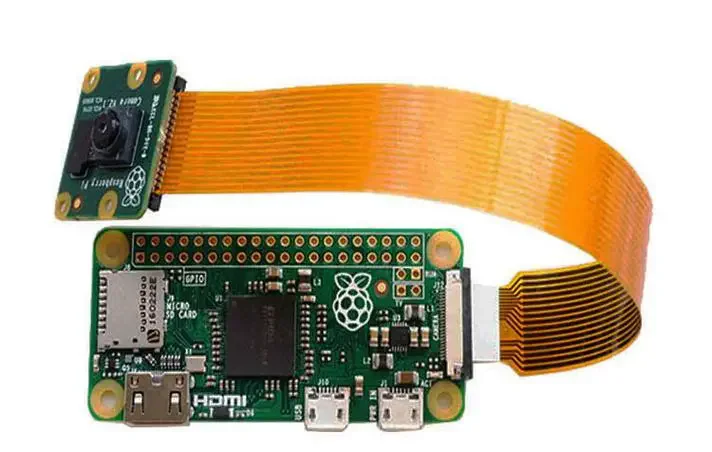

Rigid-flex PCB Assembly

Rigid-Flex PCBs are a type of printed circuit board that combines rigid and flexible substrates within a single unit. These PCBs are ideal for applications where both flexibility and structural stability are required. The rigid sections provide support and protection, while the flexible parts allow the PCB to bend, twist, and fit into compact or irregular spaces. Rigid-flex PCBs are often used in high-performance applications, such as aerospace, medical devices, and wearables.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

Rigid-Flex PCBs are a type of printed circuit board that combines rigid and flexible substrates within a single unit. These PCBs are ideal for applications where both flexibility and structural stability are required. The rigid sections provide support and protection, while the flexible parts allow the PCB to bend, twist, and fit into compact or irregular spaces. Rigid-flex PCBs are often used in high-performance applications, such as aerospace, medical devices, and wearables.

What is Rigid-Flex PCB and Why is It Important?

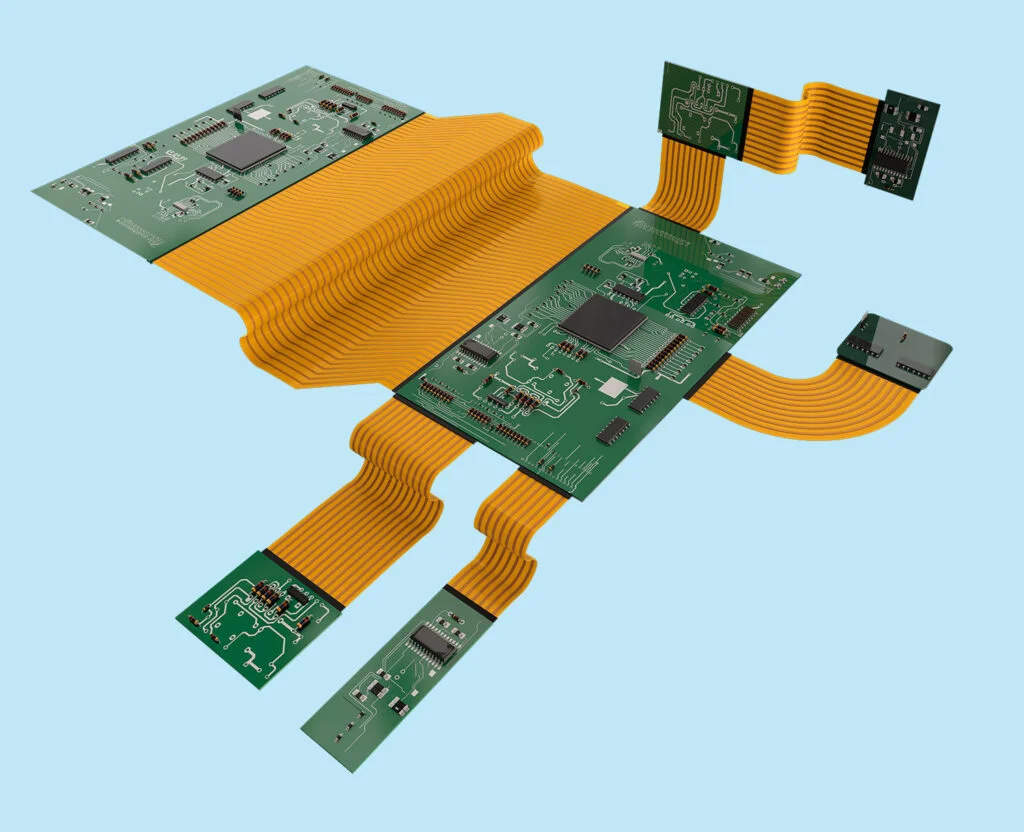

Rigid-Flex PCBs are a hybrid of rigid and flexible printed circuit boards. They combine the benefits of both technologies in a single unit:

- Rigid Sections: These provide stability, mechanical support, and protection for sensitive components.

- Flexible Sections: These parts can bend, twist, and flex, making the PCB ideal for applications where space is limited or where the board must conform to a specific shape.

By using both rigid and flexible sections, rigid-flex PCBs are able to achieve a balance of flexibility, strength, and durability that cannot be achieved with rigid or flexible PCBs alone.

What Are the Disadvantages of Rigid-Flex PCB?

While rigid-flex PCBs offer significant advantages, they also come with some challenges:

- Higher Cost: The manufacturing process for rigid-flex PCBs is more complex and involves more steps than traditional rigid or flexible PCBs, leading to higher costs.

- Manufacturing Complexity: Assembling rigid-flex PCBs requires specialized techniques and equipment due to their hybrid nature.

- Design Challenges: Designing a rigid-flex PCB involves complex layout considerations to ensure that both rigid and flexible sections function correctly together.

Despite these challenges, rigid-flex PCBs are highly sought after for applications where both rigidity and flexibility are needed in a compact design.

Rigid-Flex PCB Assembly Cost: What You Need to Know

The cost of rigid-flex PCB assembly depends on several factors:

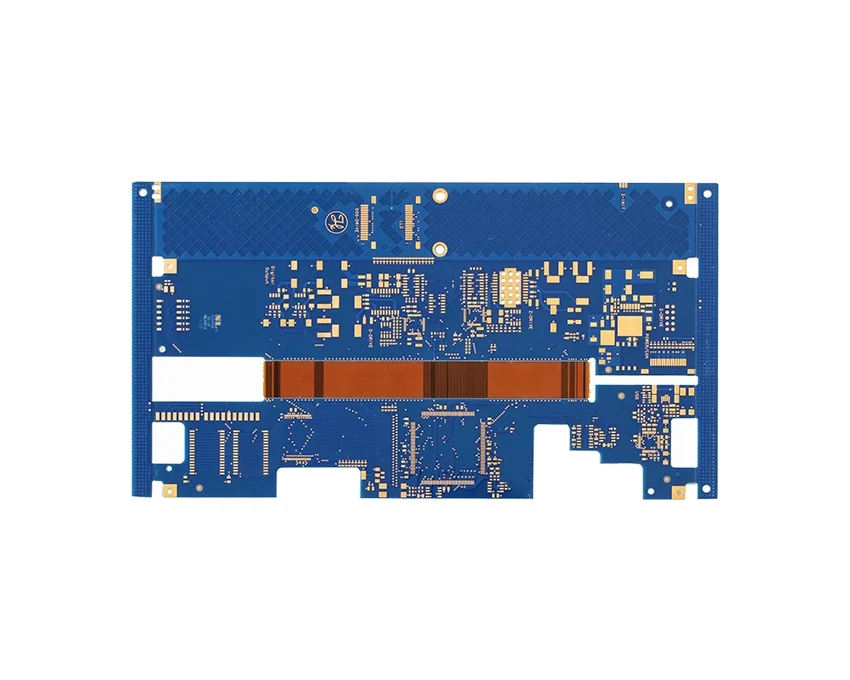

- Design Complexity: More intricate designs with multiple layers or fine traces can increase costs.

- Volume: Larger orders tend to reduce the per-unit cost as economies of scale come into play.

- Materials Used: The cost of high-quality materials, such as polyimide films for the flexible sections, can impact the overall price.

- Manufacturing Location: Labor and material costs vary by region and can affect pricing.

On average, rigid-flex PCBs can cost anywhere from $15 to $150 per unit, depending on these factors.

Popular Applications of Rigid-Flex PCB Assembly

Rigid-flex PCBs are used in a variety of industries, particularly where space-saving and durability are crucial. Here are some common applications:

- Wearable Electronics: Devices like smartwatches and fitness trackers often use rigid-flex PCBs to maintain compactness and flexibility.

- Medical Devices: Used in devices such as diagnostic tools, implantable devices, and health monitoring systems.

- Aerospace: Rigid-flex PCBs are essential in aerospace applications, where both flexibility and stability are needed in harsh environments.

- Automotive: In automotive systems like airbags, cameras, and power control units, rigid-flex PCBs provide a reliable solution.

Rigid-Flex PCB vs Rigid PCB vs Flexible PCB: Which is Right for You?

When choosing between rigid-flex, rigid, and flexible PCBs, consider the needs of your application. Here’s a quick comparison of the three:

| Feature | Rigid-Flex PCB | Rigid PCB | Flexible PCB |

|---|---|---|---|

| Flexibility | Combines flexibility and rigidity | Rigid and inflexible | Flexible and bendable |

| Applications | Aerospace, medical, wearables, automotive | Consumer electronics, industrial | Wearable tech, medical, aerospace |

| Cost | Higher due to complexity | Lower for mass production | Higher due to material complexity |

Rigid-flex PCBs are ideal for applications requiring both flexible and rigid sections, while rigid PCBs and flexible PCBs serve their respective niches.

Why Choose Unit Circuits As Your Partner?

When it comes to PCB assembly, Unit Circuits stands out as a trusted partner for businesses looking for reliable, high-quality services. Here’s why:

- Quality Assurance

Unit Circuits employs the latest SMT technology to ensure the highest quality standards. From thorough inspection to rigorous testing, your project will meet industry standards. - Fast Turnaround

With our automated processes and experienced team, we offer quick assembly times, helping you reduce your time-to-market. - Competitive Pricing

We offer affordable pricing without compromising on quality. Our efficient process ensures cost savings for your project. - Comprehensive Services

From PCB design to final assembly, Unit Circuits offers end-to-end solutions for your SMT needs, making it easy to manage your project under one roof.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0