Rigid PCB Assembly

High-Quality Rigid PCB Assembly Services Since 2017

- Single & Double-Sided SMT/TH Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 components, BGA, micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

Rigid PCB Assembly

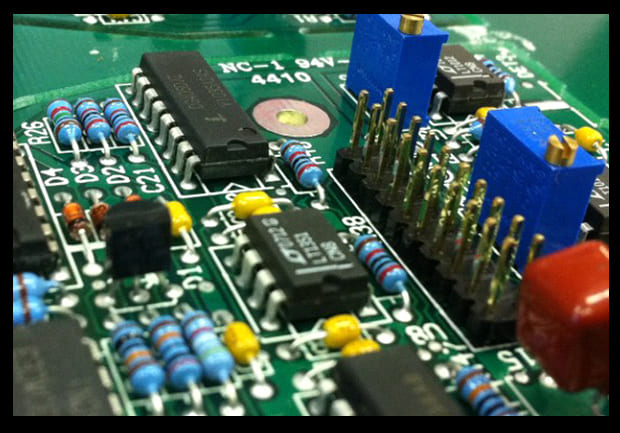

Rigid PCB Assembly is at the heart of countless electronic devices, from smartphones to medical equipment. In this guide, we’ll break down what rigid PCBs are, their applications, and why they’re crucial in modern manufacturing. Understanding this technology can help streamline your decisions when sourcing high-quality rigid PCB assembly services.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is Rigid PCB and Why is It Important?

Rigid PCBs are a type of circuit board made from solid, inflexible materials. These boards are typically constructed using several layers that are bonded together to provide stability and durability. Here’s a breakdown of the key components:

- Substrate Layer: The foundation of the PCB, typically made of fiberglass or other rigid materials.

- Copper Layer: Forms the electrical connections and traces on the board.

- Solder Mask Layer: Insulates the copper traces, preventing short circuits.

- Silk Screen Layer: Adds markings, labels, and identifiers for assembly and troubleshooting.

Rigid PCBs are essential for applications requiring high stability, durability, and precision, making them the go-to choice for many industries.

What Are the Disadvantages of Rigid PCB?

While rigid PCBs offer several advantages, they come with some limitations:

- Limited Flexibility: Unlike flexible PCBs, rigid PCBs cannot bend or conform to curved surfaces. This makes them unsuitable for applications where flexibility is needed.

- Size Constraints: Rigid PCBs may not always fit into compact or irregularly shaped devices, making them less suitable for space-constrained environments.

Despite these limitations, rigid PCBs remain popular for applications where stability and cost-effectiveness are key.

Rigid PCB Assembly Cost: What You Need to Know

The cost of rigid PCB assembly can vary significantly depending on various factors:

- Design Complexity: More intricate designs with finer traces and multiple layers typically cost more to assemble.

- Order Volume: Larger orders tend to reduce the per-unit cost, as economies of scale come into play.

- Automation: Fully automated processes can help reduce labor costs, but may increase initial setup costs.

- Geography and Labor: Manufacturing costs can vary by region, as labor costs differ across countries.

- In general, rigid PCB assembly costs can range from $5 to $50 per board, depending on these variables.

Rigid PCB vs Flexible PCB: Which is Right for You?

When deciding between rigid and flexible PCBs, it’s important to consider the needs of your project. Here’s a side-by-side comparison of the two:

Feature Rigid PCB Flexible PCB Flexibility Inflexible, rigid structure Can bend and flex Applications Automotive, medical, industrial Wearable tech, aerospace, cameras Cost Lower for mass production Higher due to material complexity Rigid PCBs are best suited for stable environments requiring durable components, while flexible PCBs are ideal for applications needing flexibility and adaptability.

The Rigid PCB Assembly Process Step-by-Step

The rigid PCB assembly process is composed of several key steps:

- Design and Prototyping: First, the PCB layout is designed, and prototypes are created for testing.

- Fabrication: The board is fabricated, which involves etching the copper traces and layering the materials together.

- Component Placement: Components like resistors, capacitors, and microchips are placed onto the board.

- Soldering: The components are soldered into place using various techniques such as wave soldering or reflow soldering.

- Testing: Finally, the PCB undergoes functional and quality testing to ensure it meets performance standards.

Popular Applications of Rigid PCB Assembly

Rigid PCBs are used in various industries due to their strength, stability, and cost-effectiveness. Here’s a deeper look into some of the most common applications:

- Automotive: Engine control units (ECUs), Advanced Driver Assistance Systems (ADAS), and infotainment systems rely on rigid PCBs for stability and performance.

- Medical Equipment: Portable diagnostic tools, patient monitors, and imaging devices like MRIs are commonly built with rigid PCBs.

- Consumer Electronics: Smartphones, laptops, and gaming consoles rely heavily on rigid PCB technology.

- Industrial Systems: Automation systems, control panels, and power distribution units often use rigid PCBs to ensure reliable operation.

Why Choose Unit Circuits As Your Partner?

When it comes to PCB assembly, Unit Circuits stands out as a trusted partner for businesses looking for reliable, high-quality services. Here’s why:

- Quality Assurance

Unit Circuits employs the latest SMT / TH technology to ensure the highest quality standards. From thorough inspection to rigorous testing, your project will meet industry standards. - Fast Turnaround

With our automated processes and experienced team, we offer quick assembly times, helping you reduce your time-to-market. - Competitive Pricing

We offer affordable pricing without compromising on quality. Our efficient process ensures cost savings for your project. - Comprehensive Services

From PCB design to final assembly, Unit Circuits offers end-to-end solutions for your SMT needs, making it easy to manage your project under one roof.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0