Quick Leads

How to Save Money on PCB Assembly: Understanding the Key Cost Factors

Introduction

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

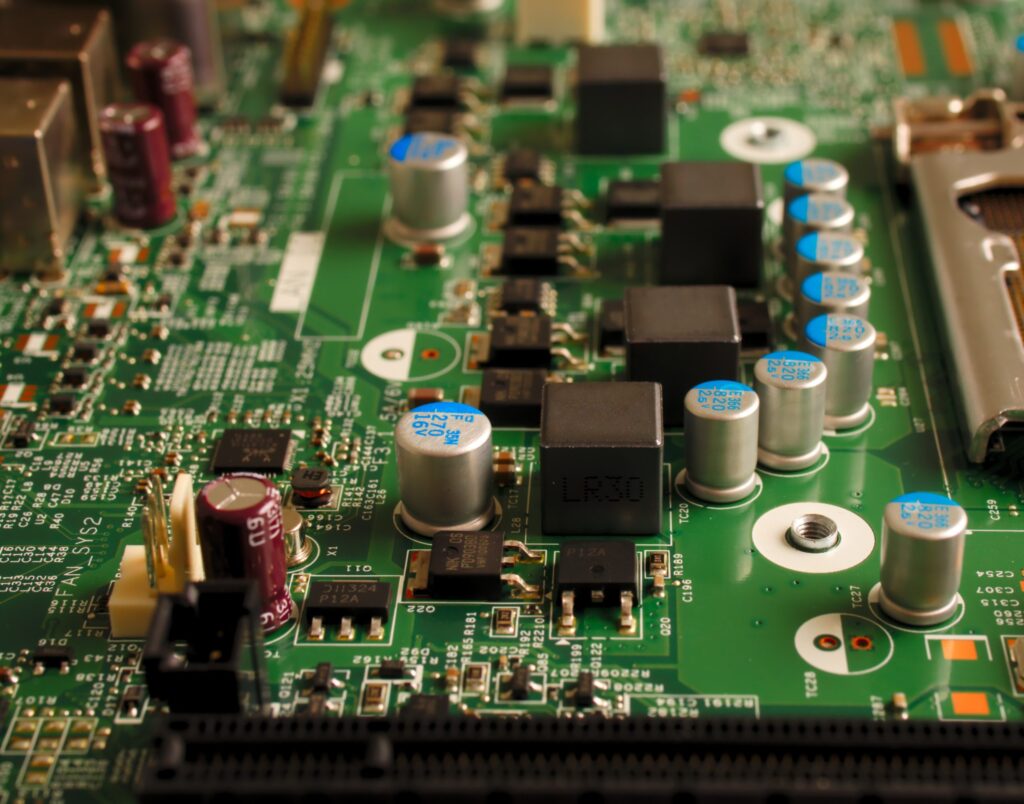

Minimizing Board Complexity for Cost Efficiency

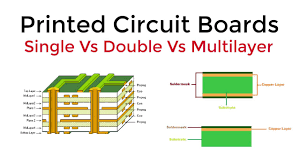

- Reduce the Number of Layers: Simplifying the design by reducing the number of layers can save you a lot of money. Fewer layers mean less material and labor, which directly lowers your production costs.

- Avoid Unnecessary Features: By getting rid of features you don’t need, you can streamline the assembly process and save money.

- Optimize Trace Widths and Spacing: Using the right trace widths and spacing can help you avoid manufacturing errors, which saves you money

Optimizing Panel Size: The Key to Reducing Waste

- Work with Your Manufacturer: Work closely with your manufacturer to figure out the best panel size. This can save you a lot of money on materials and production costs.

- Maximize Utilization: Arrange the layout of your PCB on the panel to use the space as efficiently as possible. If you use the panel efficiently, you’ll need fewer panels, which will save you money.

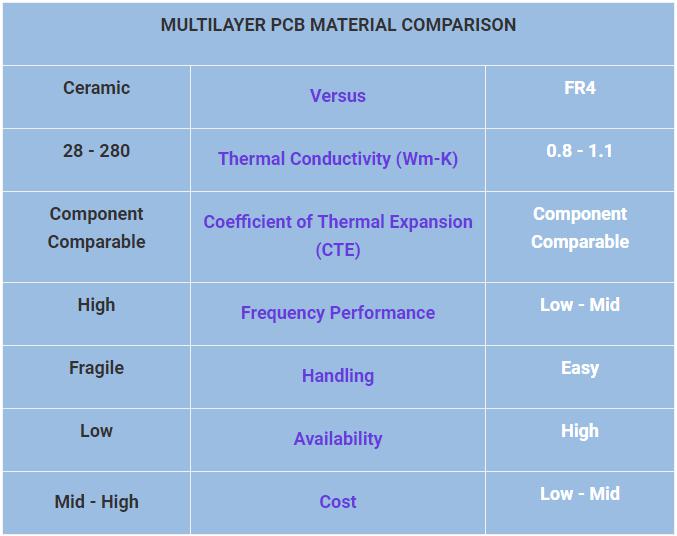

Using Cost-Effective PCB Materials

- Stick to FR4: FR4 laminated fiberglass is the most common and cost-effective material for PCBs. While other materials like aluminum or ceramic have their advantages, they’re usually more expensive and should only be used when you really need them.

- Consider Alternatives for Specific Needs: If your design needs certain material properties, think carefully about whether you really need to spend the extra money on more expensive materials.

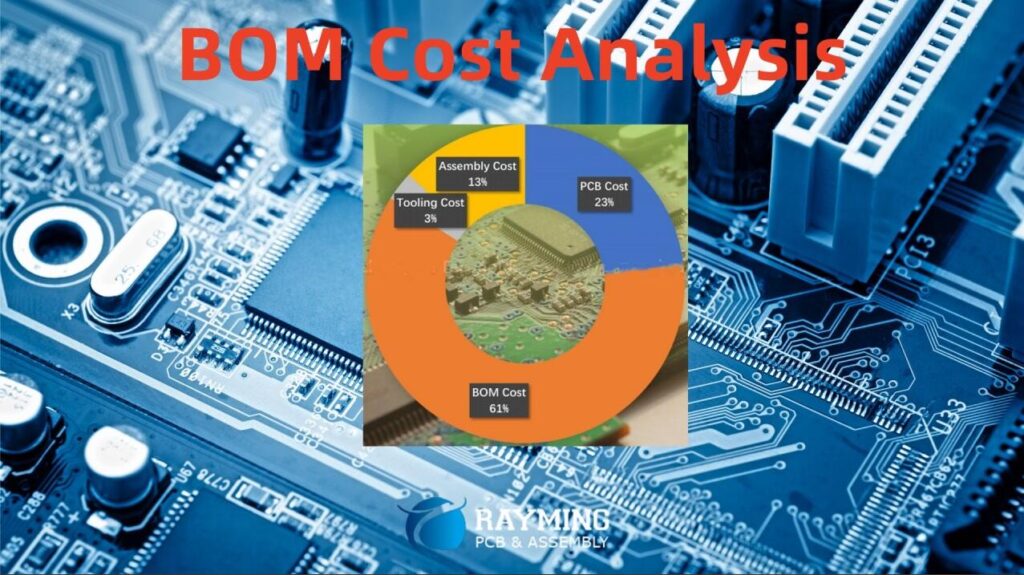

Why is PCB Assembly So Expensive?

- Circuit Complexity: More complex circuits need more components, which means you have to buy more parts and it takes longer to put everything together. Simplifying your circuit design can help you save money.

- Component Sourcing: The availability and lead times of components can also affect your costs. Components that are in high demand may cost more, and if you have to wait a long time to get them, that can slow down your production and cost you money.

Real-Life Example: How Optimizing PCB Design Saved a Manufacturer 20%

- Design Simplification:They got rid of two of the layers in their PCB design, which saved them 15% on materials.

- Component Standardization:They started using standard components that were easy to find, which saved them 10% on components.

- Panel Optimization:They started using their panels more efficiently, which saved them another 5% on production costs.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

Simplify your design, use your panels more efficiently, and pick the right materials, like FR4. Also, work with your manufacturer to find places where you can save money without hurting your performance.

FR4 is the most common and cheapest material for most jobs. If you need something really fancy, you can use ceramic, but it’s more expensive.

Key Takeaways

- Simplify Your Design:The simpler your board is, the cheaper it is to make.

- Optimize Panel Size:Using your panels efficiently helps you make fewer panels and save money.

- Choose the Right Materials:Use FR4 unless you have a really good reason not to.

- Collaborate Early: Work closely with your manufacturer to identify cost-saving opportunities from the get-go.

Conclusion

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!