SMT Assembly

High-Quality PCB Assembly Services Since 2017

- Single & Double-Sided SMT Assembly

- Flexible Options: Consigned, Partial Turnkey, Full Turnkey

- No MOQ & Competitive Pricing

- E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

- ISO 9001:2015, ISO 13485:2016, UL Listed

- Supports 0201 components, BGA, micro-BGA, QFN, DFN, CSP

- Serving Medical, Automotive, Telecom, and more

SMT Assembly

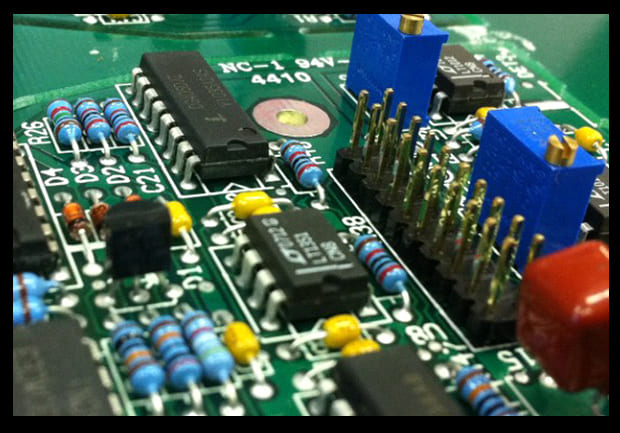

Surface Mount Technology (SMT) is a method used in the electronics industry to assemble electronic circuits by mounting components directly onto the surface of a printed circuit board (PCB). SMT has revolutionized the manufacturing process, offering greater efficiency, cost savings, and the ability to create smaller, more reliable electronic devices. Whether you’re a beginner, a professional, or a business owner looking to outsource SMT assembly, this guide will walk you through everything you need to know.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is SMT Assembly?

Surface Mount Technology (SMT) is a process in which electronic components are mounted directly onto the surface of a printed circuit board (PCB). Unlike traditional through-hole technology (THT), where components are inserted into holes drilled in the board, SMT components are designed to sit flat against the PCB. This method allows for higher component density and faster production times, making it ideal for modern electronic devices.

Why is SMT important? It has become the standard in PCB assembly due to its ability to streamline the manufacturing process, reduce the size of electronic devices, and cut down on costs.

What is the SMT assembly process?

Surface mount technology (SMT) is the process wherein components are mounted onto the surface of a printed circuit board. The components are designed specifically to be directly mounted, rather than hardwired, onto the circuit board for the vast majority of electronics.

The Benefits of SMT PCB Assembly

SMT offers a wide array of benefits, making it the go-to choice for most electronic assembly projects. Here are the key advantages:

- 1.Compact Designs

SMT allows for smaller components, which leads to more compact circuit boards. This enables the production of smaller, more portable devices such as smartphones, wearables, and other consumer electronics.

- 2.High-Speed Production

The automation involved in SMT assembly reduces production times significantly. This means faster turnaround times for projects, reducing time-to-market.

- 3.Cost-Effective

Due to its efficiency and automation, SMT typically reduces labor costs. Additionally, the high-density design means fewer components are needed, lowering material costs as well.

- 4.Increased Reliability

SMT components are more reliable than traditional through-hole components because there are no holes drilled in the board, reducing the risk of damage during assembly and improving overall durability.

What does SMT stand for?

SMT stands for surface mount technology, an automated PCB assembly process that places, mounts, and solders electronic components to the surface of a printed circuit board.

The Common Defects in SMT Assembly

While SMT has many advantages, it is not without its challenges. Some common defects include:

- Soldering Defects

Improper soldering can lead to cold joints, bridges, or insufficient solder, affecting the functionality of the circuit. - Component Misplacement

Automated placement machines can sometimes misplace components, causing malfunctions in the circuit. Regular machine calibration and inspection are key to preventing this issue. - Warping

Warping occurs when the PCB is subjected to high temperatures during the soldering process. This can result in poor component placement and electrical connectivity issues.

To prevent these defects, proper setup, inspection, and testing at various stages of the assembly process are essential.

What is SMT setup?

SMT setup refers to the process in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). Ensuring the proper setup can minimize common assembly defects.

The Key Processes in SMT PCB Assembly

SMT assembly involves several key stages. Here’s a step-by-step look at the process:

- 1.Board Preparation

The PCB is cleaned and prepared for component placement. Any residues or contaminants are removed to ensure a clean surface for soldering.

- 2.Solder Paste Application

Solder paste is applied to the PCB pads using a stencil. This paste will later be melted to create the solder joints that connect the components to the board.

- 3.Component Placement

Automated pick-and-place machines position the SMT components onto the solder paste-coated pads.

- 4.Reflow Soldering

The assembled board is passed through a reflow oven, where heat is applied to melt the solder paste, creating permanent solder joints.

- 5.Inspection and Testing

After assembly, the board undergoes thorough inspection and testing to ensure all components are properly placed and soldered.

What is the SMT process?

SMT places and solders components on the PCB pads that are on the surface of the circuit board. The PCB assembly process includes paste application, component placement, reflow soldering, and final inspection.

Why Choose Unit Circuits As Your Partner?

When it comes to SMT PCB assembly, Unit Circuits stands out as a trusted partner for businesses looking for reliable, high-quality services. Here’s why:

- Quality Assurance

Unit Circuits employs the latest SMT technology to ensure the highest quality standards. From thorough inspection to rigorous testing, your project will meet industry standards. - Fast Turnaround

With our automated processes and experienced team, we offer quick assembly times, helping you reduce your time-to-market. - Competitive Pricing

We offer affordable pricing without compromising on quality. Our efficient process ensures cost savings for your project. - Comprehensive Services

From PCB design to final assembly, Unit Circuits offers end-to-end solutions for your SMT needs, making it easy to manage your project under one roof.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0