Quick Leads

What Does SMT Mean? A Detailed Guide

Understanding Surface-Mount Technology (SMT) in Electronics Manufacturing

In the fast-paced world of electronics manufacturing, Surface-Mount Technology (SMT) has become a fundamental building block of modern production techniques.

Whether you’re new to the field or a seasoned professional, understanding SMT is a must. This guide aims to give you a clear and complete overview of what SMT is, how it works, and why it matters.

What is Surface-Mount Technology (SMT)?

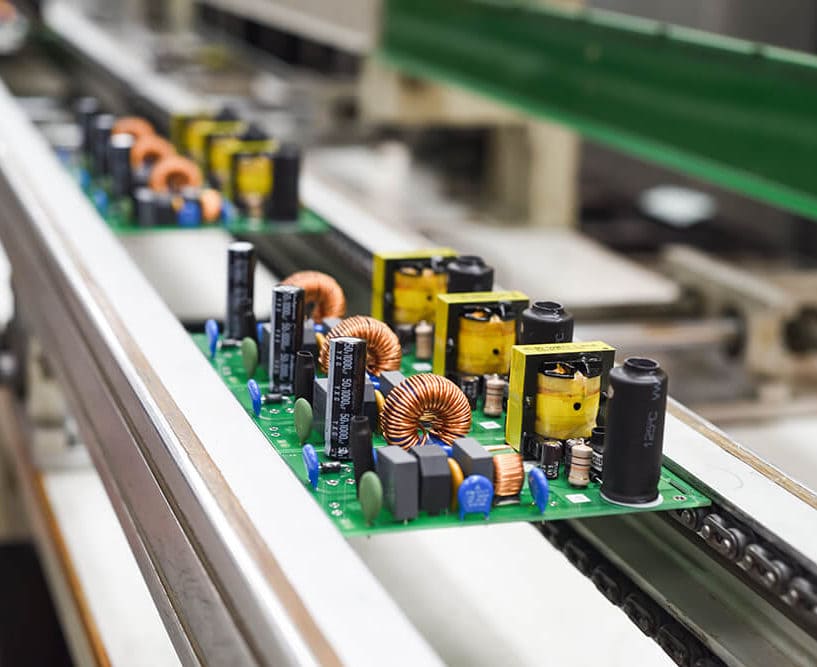

Surface Mount Technology (SMT) is a way to put electronic parts on a printed circuit board (PCB). Instead of putting the leads of the part through holes in the PCB, SMT puts the part on top of the board.

This lets the manufacturer make smaller, more efficient designs. That’s important because everything is getting smaller.

How Does the SMT Process Work?

SMT is highly automated, which makes it fast and accurate. Here’s how it works:

1.Stencil Printing:

Solder paste is put on the board through a stencil. The stencil has holes in it so the solder paste only goes where the parts will be.

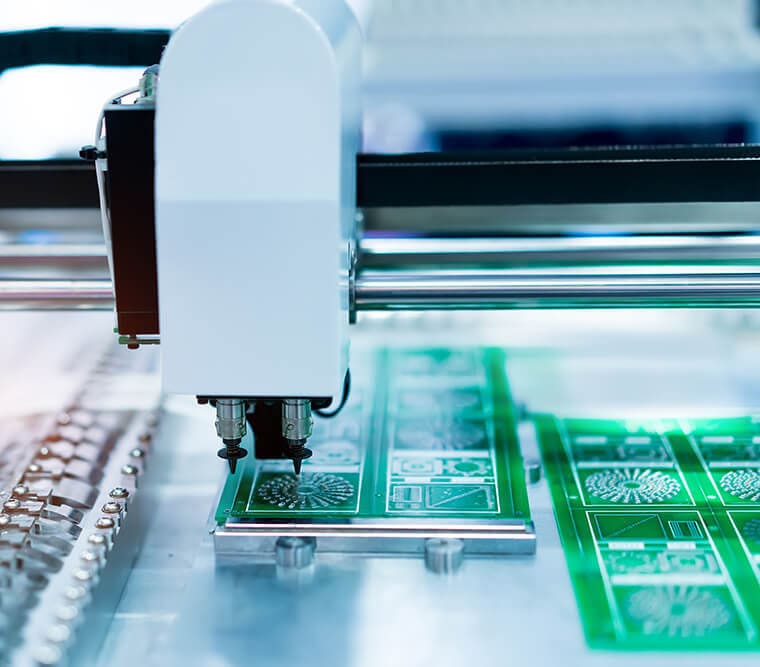

2.Pick and Place:

Machines put the parts on the solder paste.

3.Reflow Soldering:

The board goes into a reflow oven. The oven gets hot and melts the solder paste. The melted solder makes the parts stick to the board.

This way, there’s less chance for people to make mistakes. It also costs less to make things this way. And, it’s faster.

Advantages of SMT in Electronics Manufacturing

SMT is better than the old way of doing things. That’s why everybody does it now.

- Miniaturization: SMT lets you make smaller, more complicated circuits. That’s important because everything is getting smaller.

- Cost-Effectiveness:SMT is faster and cheaper than the old way of doing things.

- Improved Performance: SMT components are often better electrically because they have shorter leads, which means less resistance and inductance.

Applications of SMT Across Industries

SMT is used in a lot of different industries, and each industry gets to take advantage of the unique benefits of the technology:

- Consumer Electronics: From smartphones to laptops, SMT lets us make high-density circuits, which are important for modern devices.

- Automotive: SMT is a big deal in the automotive industry because it lets us make small and reliable electronic control units (ECUs).

- Telecommunications: High-speed and high-frequency circuits in telecommunications equipment depend a lot on SMT for their performance and reliability.

- Medical Devices: The small size that SMT gives us is really important in making small, life-saving medical devices.

SMT vs. Through-Hole Technology: What’s the Difference?

While Surface-Mount Technology (SMT) has mostly replaced Through-Hole Technology (THT) in a lot of places, both of them have their place in electronics manufacturing. Here’s a quick comparison:

Feature | Surface-Mount Technology (SMT) | Through-Hole Technology (THT) |

Component Size | Smaller, allowing for compact designs | Larger, making circuits bulkier |

Component Placement | Components can be placed on both sides of the PCB | Components are typically placed on one side only |

Assembly Process | Highly automated, faster, and more cost-effective | Requires manual intervention, slower, and more labor-intensive |

Mechanical Strength | Lower mechanical strength, suitable for lightweight components | Higher mechanical strength, ideal for components under physical stress |

Applications | Used in high-density, high-speed circuits, like consumer electronics | Often used for connectors and components that need strong physical bonds |

Production Volume | Best suited for large-scale, high-volume production | Commonly used in low-volume or specialty manufacturing |

Electrical Performance | Better performance with reduced resistance and inductance | Slightly lower electrical performance due to longer lead lengths |

SMT Process Flow Chart

To picture the SMT process, think about an assembly line where everything is coordinated perfectly to make sure it’s as efficient as possible. You start with stencil printing, then you put the components on, and then you solder them with reflow. It’s a model of how to make stuff right.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

In summary, Surface-Mount Technology (SMT) is a big deal in the electronics manufacturing industry.

It gives us a lot of good stuff like making things smaller, saving money, and making things work better. Whether you’re just starting out or you’re a pro, knowing about SMT will help you understand how we make modern electronic devices.

If you liked this guide, you might want to look into more about SMT equipment or how SMT compares to other ways of making stuff. You’re just getting started on your journey into making electronics, and there’s a lot more to learn!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!