Quick Leads

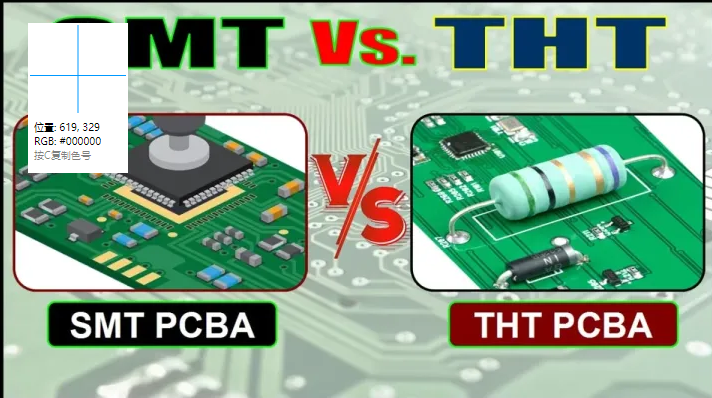

SMT vs. Through-Hole: Key Cost Differences and Which One is Right for Your Project

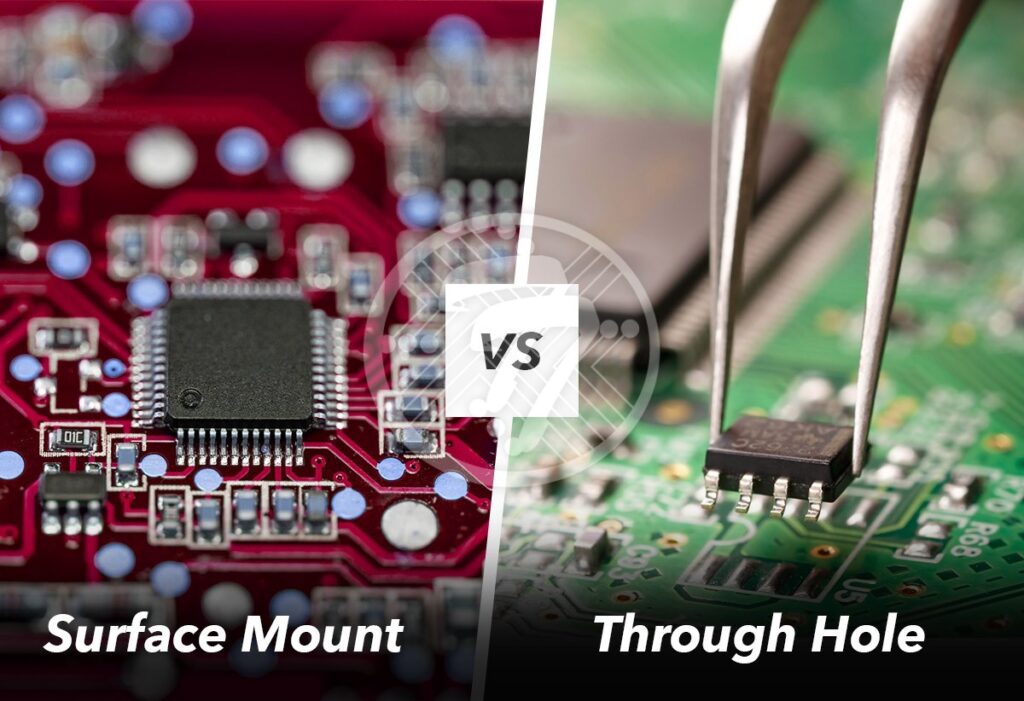

Deciding whether to use surface mount technology (SMT) or through-hole components can make a big difference in how much it costs to put your board together and how well your product works. In this article, we’ll talk about the cost differences between SMT and through-hole so you can make a good decision for your company.

If you understand how the costs work, you can make sure you get the right price, the right volume, and the right performance for your next project.

What are the Key Cost Differences Between SMT and Through-Hole Components?

Surface mount technology (SMT) is cheaper than through-hole because it costs less to put the parts on the board, you don’t have to use as much stuff, and it doesn’t take as long to do it. SMT parts are made to be put on the board by a machine, so you don’t need as many people. Through-hole parts cost more because you have to pay somebody to put them on the board, it takes longer to set up, and you have to drill holes in the board.

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Why Does SMT Offer Better Cost Efficiency than Through-Hole?

Here’s why SMT is the go-to choice for cost-effective PCB manufacturing:

- No drilling required: SMT components don’t need holes in the PCB, saving material and time.

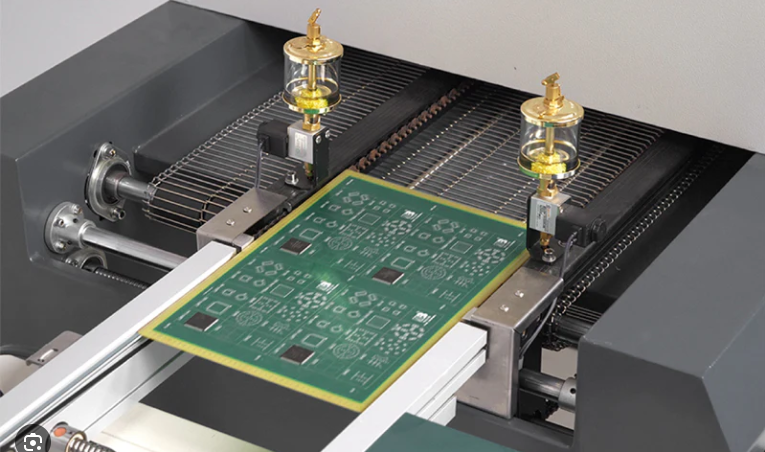

- Faster assembly: Pick-and-place machines put thousands of parts on the boards every hour, so you don’t have to pay people to do it.

- Compact designs: You can put the parts closer together, which means you can make the boards smaller and use less stuff.

These factors make SMT ideal for high-volume, scalable production.

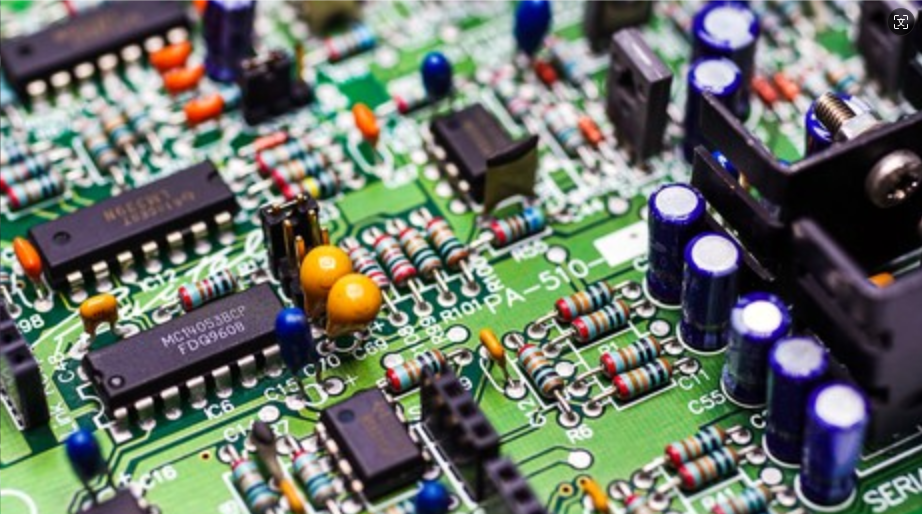

Why Do Through-Hole Components Cost More to Assemble?

Through-hole parts have some good things about them, but they also cost more money:

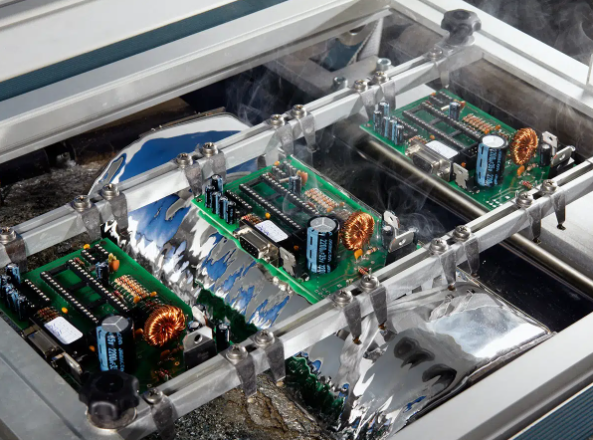

- Manual or semi-automated assembly: You have to pay people to put through-hole parts on the boards or to solder them in with a selective soldering machine.

- Drilling requirements: You have to drill holes in the boards, which takes time and costs money.

- Larger PCB sizes: You have to leave more room for through-hole parts, which means you have to use more stuff.

Through-hole parts are better for low-volume stuff or for things that have to last a long time, like airplanes, military equipment, or industrial electronics.

How Does Production Volume Affect Cost Differences?

How many you’re going to make is a big factor in whether you use surface mount or through-hole parts:

- High-volume production: If you’re going to make a lot of something, it’s cheaper to use surface mount parts.

- Small batch or prototype runs: If you’re not going to make a lot of something, it might be cheaper to use through-hole parts because you don’t have to pay to set up the surface mount stuff.

What is the Equipment Investment for SMT vs. Through-Hole Assembly?

Investing in an SMT production line requires significant capital upfront:

- SMT equipment:A good SMT line costs between $100,000 and $8,000,000, but once you get it set up, it’s cheaper to run.

- Through-hole equipment:You can buy a through-hole machine for a lot less money, but you have to pay people to run it.

You have to decide whether you want to spend a lot of money up front to get the equipment or whether you want to pay people to put the parts on the boards.

Pros and Cons of SMT vs. Through-Hole from a Cost Perspective

|

Aspect |

SMT |

Through-Hole |

|

Assembly Speed |

Fast, automated |

Slow, manual or semi-automated |

|

Labor Cost |

Low (automated) |

High (manual) |

|

Material Cost |

Lower due to no drilling |

Higher due to drilling requirements |

|

Equipment Investment |

High, reduces long-term costs |

Moderate, but less efficient |

|

Best Use Case |

Consumer electronics, compact designs |

Military, aerospace, or industrial use |

Key Takeaways: SMT vs. Through-Hole Cost Comparison

-

SMT is cost-effective for high-volume production due to automation and compact design.

-

Through-hole technology remains relevant for low-volume or high-reliability applications but is more expensive to assemble.

-

Production volume plays a key role—SMT is ideal for large runs, while through-hole suits smaller, specialized projects.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

Not always. SMT is generally cheaper for high-volume production, but for small batches or prototypes, the initial setup costs might favor through-hole assembly.

Through-hole components are better for high-reliability applications like aerospace and military projects due to their mechanical strength.

Yes, through-hole technology can be a practical choice for low-volume production or prototyping, as it requires less investment in automated equipment.

Get the Right PCB Assembly Solution for Your Needs

Need help selecting the right assembly method for your next project? Contact us today for expert advice or a competitive quote on SMT or through-hole assembly!

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRequest for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!