Quick Leads

SMT vs. THT: Which PCB Manufacturing Technology is Right for Your Needs?

Introduction

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Quick Overview: SMT vs. THT Comparison Table

|

Feature |

Surface Mount Technology (SMT) |

Through-Hole Technology (THT) |

|

Assembly Process |

Automated, high-speed |

Manual or semi-automated |

|

Cost Efficiency |

Cost-effective for high-volume production |

Higher cost due to manual labor |

|

Mechanical Strength |

Less durable under stress |

Ideal for high-stress environments |

|

Applications |

Consumer electronics, IoT devices |

Aerospace, industrial equipment |

|

Repairability |

Complex, requires special tools |

Easier to access and repair |

|

Thermal Performance |

Requires advanced heat management |

Superior heat dissipation |

Key Differences Between SMT and THT

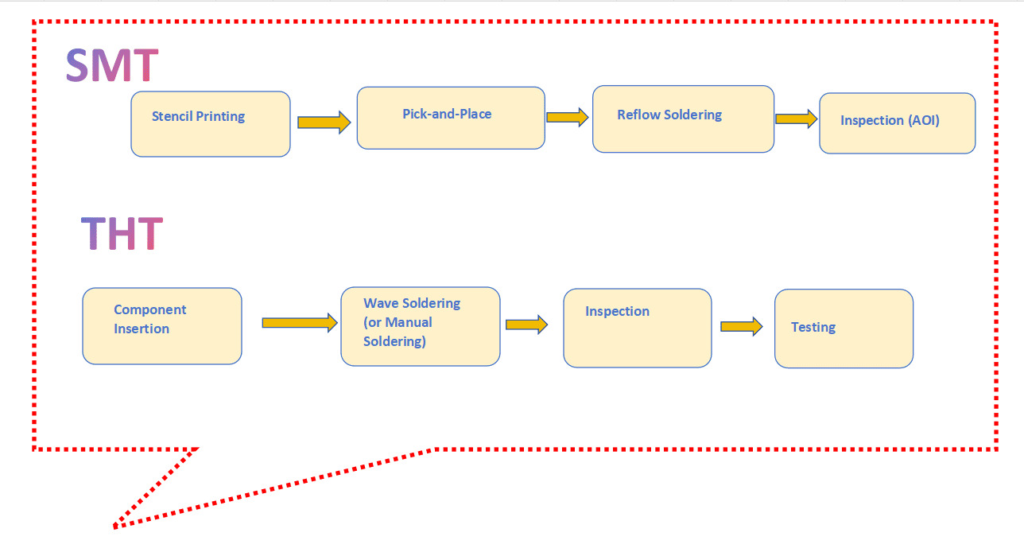

1. Assembly Process

-

SMT: Components are mounted directly onto the PCB surface using automated pick-and-place machines, ideal for high-speed, high-volume production.

-

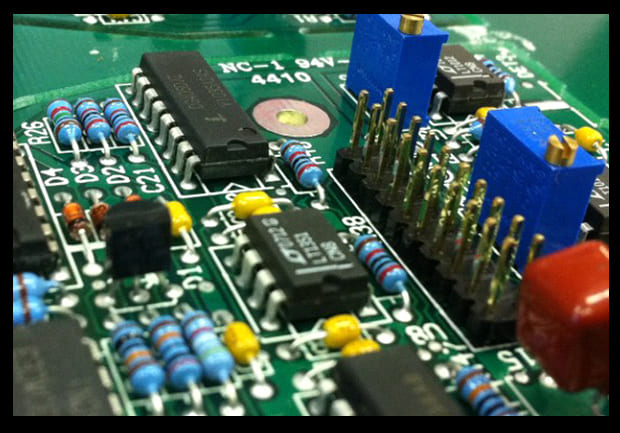

THT: Components are inserted through pre-drilled holes in the PCB and soldered, offering better mechanical strength.

2. Component Size and Density

-

SMT: Enables smaller components and double-sided PCB designs, perfect for compact, lightweight devices like IoT gadgets.

-

THT: Uses larger components, suitable for low-density layouts or high-power applications.

3. Mechanical Strength

-

THT excels in environments with vibration or mechanical stress, such as aerospace and automotive industries.

-

SMT connections, while efficient, are less durable under stress.

4. Cost Efficiency

-

SMT: Cost-effective for mass production due to its automated process.

-

THT: Higher labor costs make it more suitable for low-volume or specialized projects.

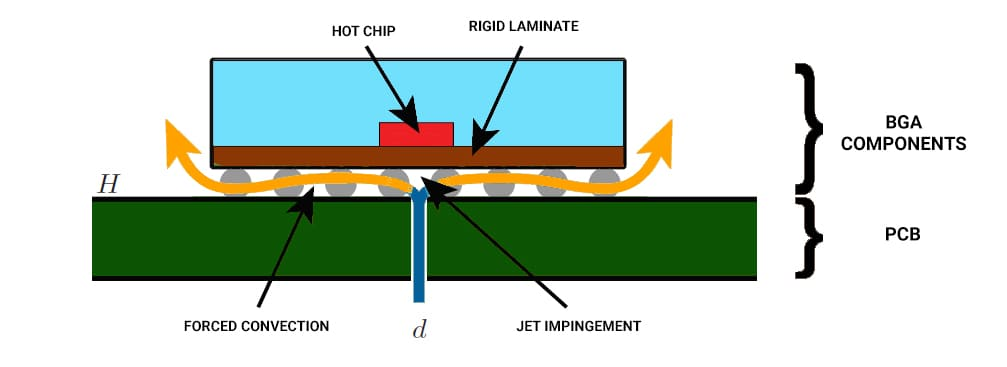

5. Thermal Performance

-

THT: Superior heat dissipation through the PCB, ideal for high-power devices.

-

SMT: Requires advanced techniques like heat sinks or thermal vias to manage heat.

Real-World Applications of SMT and THT

SMT Applications

-

Consumer Electronics: Smartphones, tablets, and wearables benefit from SMT’s compact design capabilities.

-

IoT Devices: High-speed, space-efficient designs make SMT a top choice for smart home devices.

-

Automotive Electronics: Used in lightweight systems like ADAS and infotainment.

THT Applications

-

Aerospace & Defense: Reliable under extreme conditions, ideal for mission-critical systems.

-

Industrial Equipment: Handles vibration and stress in heavy machinery and robotics.

-

Medical Devices: Preferred for high-reliability applications, like diagnostic equipment.

How SMT and THT Components Are Mounted

SMT: Surface Mounting

-

Components are soldered directly onto the PCB surface using automated processes like pick-and-place machines and reflow soldering.

-

Ideal for: Mass production of small, lightweight devices like smartphones, laptops, and wearables.

THT: Through-Hole Mounting

-

Components are inserted into pre-drilled holes in the PCB and soldered from the other side.

-

Ideal for: Applications requiring mechanical strength, such as industrial machinery and aerospace equipment.

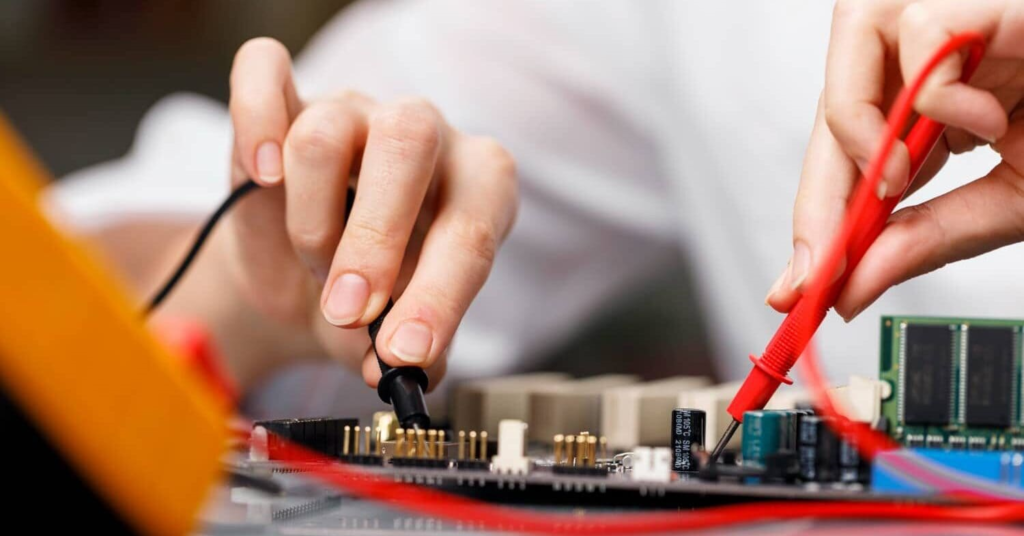

Repairability: Easier Access with THT

- THT: Easier to repair and prototype because components are accessible. Ideal for testing and customization.

- SMT: Requires specialized tools for repair, making it harder and more expensive.

Thermal Performance: Managing Heat in PCB Design

- THT: Better at dissipating heat due to leads that extend through the PCB. Suitable for high-power applications.

- SMT: Requires additional thermal management techniques like heat sinks or thermal vias to avoid heat buildup.

Frequently Asked Questions

SMT mounts components on the PCB surface, enabling compact, high-density designs, while THT involves drilling holes for stronger, more durable connections.

- SMT: Best for high-volume production with cost and space efficiency.

- THT: Suitable for prototypes and high-stress environments like aerospace.

Yes! Many designs use SMT for compact components and THT for high-stress parts to achieve optimal performance and reliability.

- Faster production.

- Lower costs for large volumes.

- Supports double-sided, high-density PCB designs.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverBuild Your Perfect PCB with Unit Circuits

- No MOQ.

- Fast quotes and delivery.

- Comprehensive quality testing.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!