Quick Leads

The Most Comprehensive Introduction to PCB Components

Printed Circuit Boards (PCBs) are at the heart of almost every modern electronic device. PCBs connect all the electronic components that make your smartphone, computer, or any other electronic device work. If you’re an engineer, designer, hobbyist, or student, you need to understand PCB components, their types, and their roles in PCB design. In this guide, I’ll cover the most common PCB components, explain how they work, and talk about why they’re important in circuit design.

What Are PCB Components and Why Are They Important in Electronics?

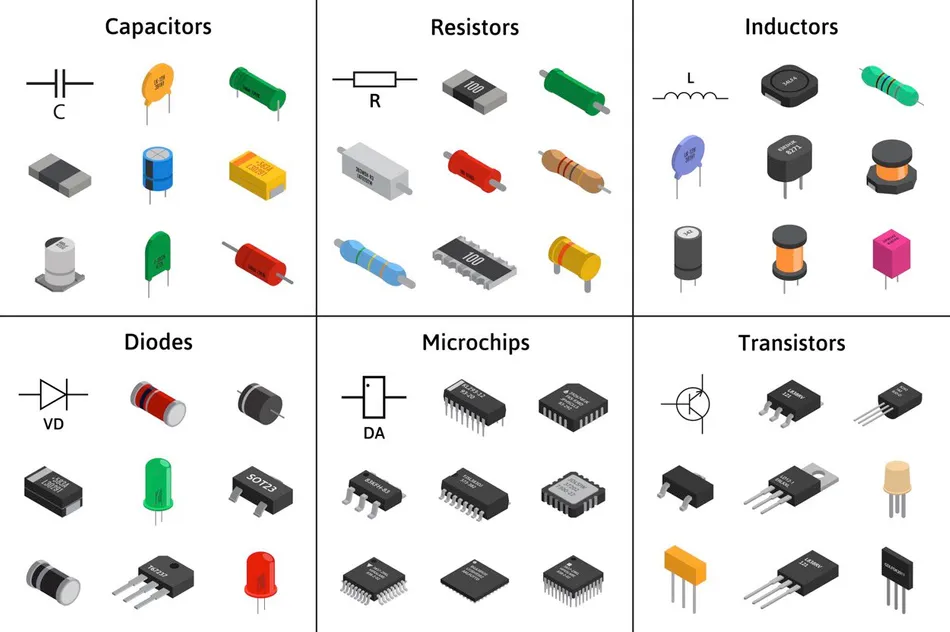

PCB components are the building blocks of any printed circuit board. These components include both passive and active elements, such as resistors, capacitors, diodes, and transistors. The functionality of a PCB depends entirely on the careful arrangement and operation of these components. Without them, devices like smartphones, laptops, and televisions wouldn’t work.

In PCB design, engineers must select the right components to meet specific needs. Each part has a job to do, whether it’s controlling voltage, regulating current, or switching things on and off. When you understand how PCBs work, you can design better circuits, troubleshoot them faster, and optimize them.

Key Types of PCB Components and Their Roles in Circuit Design

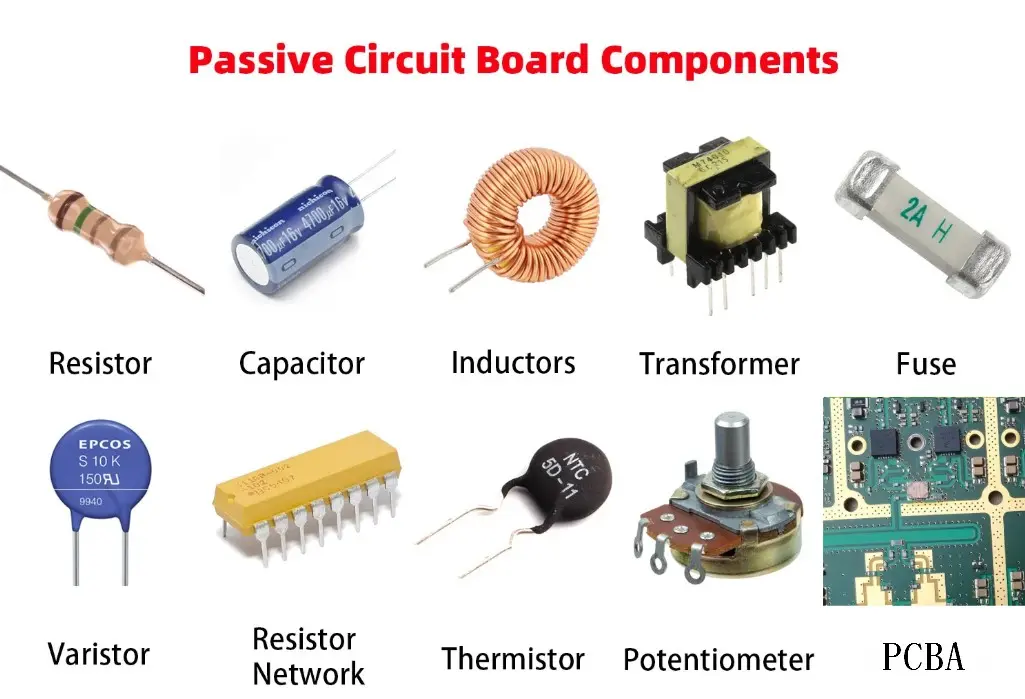

PCB components fall into two primary categories: passive and active components. Each type has a unique function that contributes to the overall operation of the circuit.

Passive vs. Active PCB Components: Understanding Their Functions

-

Passive Components: These components don’t generate energy; they merely resist, store, or dissipate it. Common examples include:

-

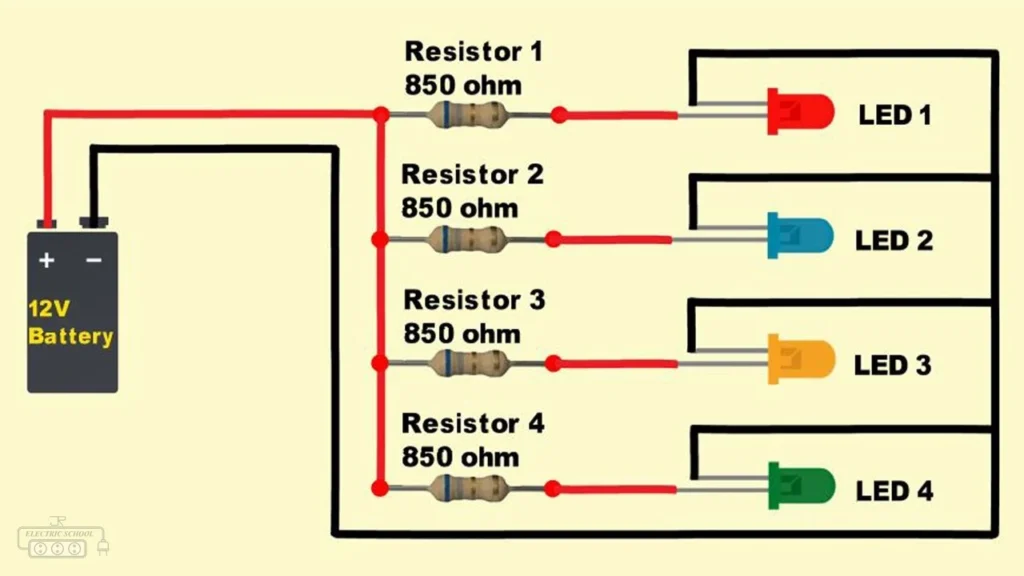

Resistors: Control the amount of current that flows through a circuit. For instance, resistors are used in LED circuits to limit the current and prevent damage.

-

Capacitors: Store and release electrical energy, helping to smooth out voltage fluctuations. Capacitors are essential in power supply circuits to stabilize voltage.

-

Inductors: Store energy in a magnetic field and are often used for filtering and noise reduction in power supplies.

-

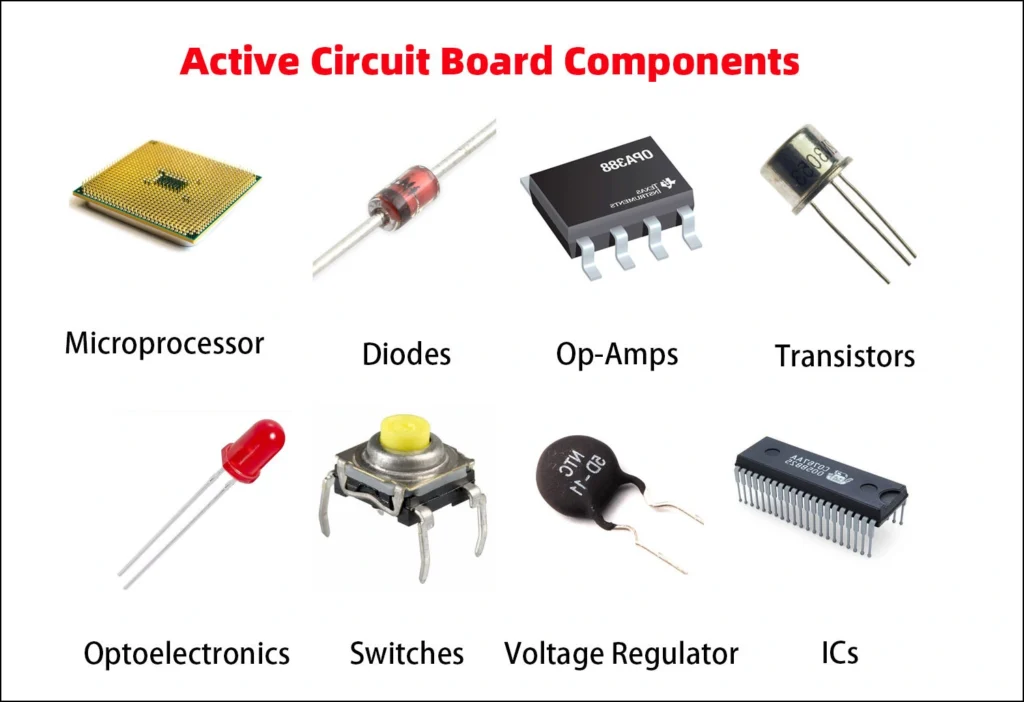

Active Components in PCB Design

Active components are used to manage signals, control current, and power devices. In PCB design, choosing the right transistor or diode for specific tasks ensures that the circuit performs optimally. For example:

-

Transistors are like switches or amplifiers. They control the flow of electrical signals based on what other parts of the circuit tell them to do..

-

Diodes are key to preventing reverse currents, protecting sensitive components from potential damage.

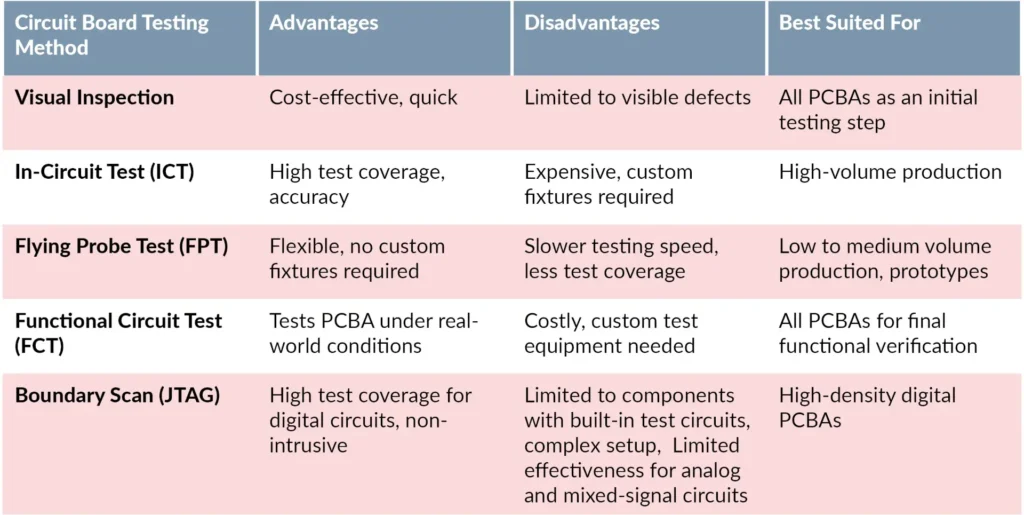

PCB Testing Methods: Ensuring Component Quality

Before a PCB is used in a device, it undergoes rigorous PCB testing methods to ensure all components are functioning correctly. The following are some of the most common testing techniques:

-

Visual Inspection: This is usually the first thing you do. You look at the board and see if anything is obviously wrong, like a broken trace or a part that’s in the wrong place.

-

In-Circuit Testing (ICT): Involves testing individual components on the PCB for proper functionality.

-

Flying Probe Testing: Probes move across the PCB to check for open or short circuits without needing test fixtures.

-

Automated Optical Inspection (AOI): Cameras are used to inspect the board for manufacturing defects.

-

X-Ray Inspection: Used for multi-layer PCBs, this test helps detect internal defects that aren’t visible on the surface.

-

Burn-In Testing: You put parts through tough conditions to find problems before they become big problems.

-

Functional Testing: This is the big test. You make sure the whole board does what it’s supposed to do in a pretend real-life situation.

Each of these tests is critical in ensuring that a PCB meets quality standards and is ready for use in final products.

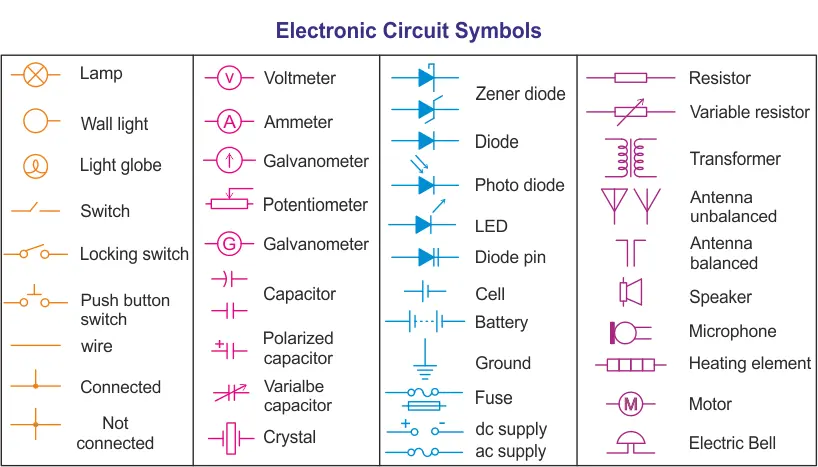

Common PCB Component Symbols Explained

In PCB design, each part has a special symbol on the schematic. These symbols help you understand what the circuit does and how it’s put together.. Some common PCB component symbols include:

-

Resistor: A zigzag line or rectangle.

-

Capacitor: Two parallel lines, often with a curved line to indicate polarity.

-

Transistor: A combination of lines and arrows, showing how current is controlled.

-

Diode: A triangle pointing to a line, showing the direction of current flow.

These symbols are important for making good circuit diagrams that tell you how to put the board together.

How to Identify PCB Components

Identifying components on a PCB layout can be tricky, especially on complex boards. Here are some helpful tips for identifying PCB components:

-

Labels: Most PCBs will have labels printed next to each component (e.g., R1 for the first resistor, C1 for the first capacitor).

-

Diagrams: Component diagrams or PCB schematics provide a map of where each component is located and what it does.

-

Multimeter: You can use a multimeter to test parts like resistors, capacitors, and diodes to see if they work.

When you know how to find and test parts, you can fix boards faster and better.

Provide Practical Examples

To understand PCB components better, let’s look at some practical examples. For example, resistors are often used in LED circuit boards to limit the amount of current that flows through the LED, protecting it from damage.. Similarly, Capacitors are used in power supply circuits to help stabilize voltage and smooth out power fluctuations.

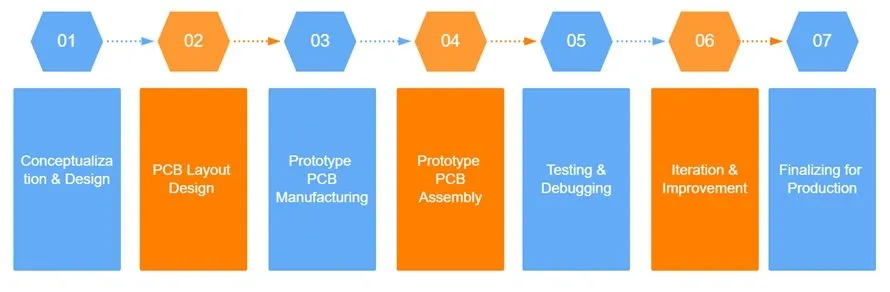

PCB Manufacturing Process

PCB manufacturing involves several steps, including design, layout, component placement, soldering, and testing. Each step is essential to ensure that the final PCB is functional and reliable. From the first design to the final test, it’s important to understand the whole manufacturing process so you can design high-quality PCBs.

Frequently Asked Questions (FAQs)

The most common PCB components include resistors, capacitors, diodes, transistors, and ICs. These components do things like control current, amplify signals, and protect the circuit.

Passive components, like resistors and capacitors, don’t need power to work and mainly store or dissipate energy. Active components, like transistors and diodes, need power and can amplify or control electrical signals.

PCB testing ensures the functionality and reliability of the circuit before it’s used in devices. Some of the most common ways to test a PCB are to look at it, stick it in a machine, or have a machine look at it.

PCB component symbols represent the various parts of a circuit in schematic diagrams. These symbols are standardized and help engineers and designers easily understand the function and connection of each component within the PCB.

Resistors limit the current flow in a circuit, protecting sensitive components, while capacitors store and release energy. Together, they ensure smooth operation and prevent damage to other components in the PCB.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

PCB components are essential for the proper functioning of any electronic device. When you know about the different kinds of parts, like passive and active parts, and how they work, you can make your board work better. Whether you’re making a simple circuit or a big complicated thing, you have to know what each part does so you can make your stuff work right.

Want to dive deeper into PCB design and optimization? Contact us today for a free consultation or check out our detailed services for all your PCB needs.

Key Takeaways:

Understanding the Two Types of PCB Components

Importance of PCB Testing

Component Symbols are Essential for Circuit Design

Components Play Specific Roles in Circuit Functionality

Mastering PCB Design Requires Knowledge of Components

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!