Through Hole PCB Assembly

High-Quality Through-Hole PCB Assembly Services Since 2017

Single & Double-Sided Through-Hole Assembly

Flexible Options: Consigned, Partial Turnkey, Full Turnkey

No MOQ & Competitive Pricing

E-test, AOI, X-ray, ICT, FCT, Burn-in Testing

ISO 9001:2015, ISO 13485:2016, UL Listed

Supports Standard Through-Hole Components

Serving Medical, Automotive, Telecom, and more

Through Hole PCB Assembly

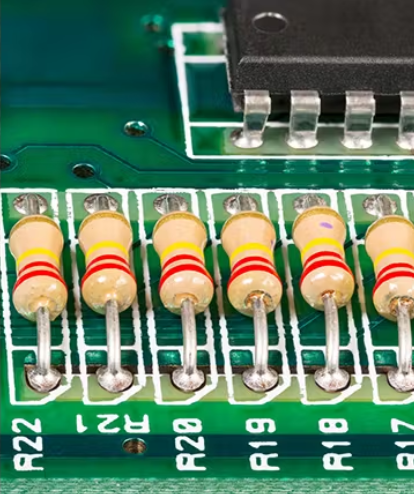

Through-Hole PCB assembly is a traditional method used in the electronics industry where electronic components are inserted into holes drilled in a printed circuit board (PCB) and then soldered into place. Although Surface Mount Technology (SMT) has become more prevalent, Through-Hole technology remains a vital part of electronics manufacturing, especially for applications requiring higher durability and reliability. Whether you’re a beginner, a professional, or a business owner looking to outsource PCB assembly, this guide will walk you through everything you need to know about Through-Hole PCB assembly.

Leading PCBA Manufacturer

Assemble 20 PCBAS for $0

What is Through-Hole PCB Assembly?

Through-Hole PCB Assembly is a process in which electronic components with leads are inserted into holes drilled in a PCB and then soldered to the board’s opposite side. This process creates a strong mechanical bond between the component and the PCB, making it ideal for applications where components need to be resistant to vibrations and physical stress.

Why is Through-Hole important? Despite the rise of Surface Mount Technology (SMT), Through-Hole technology is still widely used in specific applications, particularly for components that require high mechanical strength or for devices that need to withstand extreme environmental conditions.

What is the Through-Hole assembly process?

Through-Hole PCB assembly is a process where electronic components are inserted into pre-drilled holes in a PCB and then soldered. The process ensures strong mechanical connections, which are particularly beneficial in applications where vibration or physical stress is common.

The Benefits of Through-Hole PCB Assembly

Through-Hole PCB assembly has several advantages, particularly for certain applications. Here are the key benefits:

- 1.Strong Mechanical Bond

Through-Hole components are ideal for applications where components must be physically attached to the board with a strong mechanical connection, such as in military or automotive electronics. - 2.Ideal for High-Power Components

Through-Hole technology is well-suited for larger components like capacitors and transformers, which require more robust electrical and thermal conductivity. - 3.Greater Durability

Because of the physical connection through the holes, Through-Hole components are more durable and can withstand harsher environmental conditions compared to SMT components.

- 4.Easier to Repair

If a component needs to be replaced, Through-Hole components are easier to remove and replace compared to SMT components, making repairs more straightforward.

The Common Defects in Through-Hole PCB Assembly

While Through-Hole PCB assembly is known for its durability and reliability, it’s not without challenges. Common defects include:

- Soldering Defects

Improper soldering can lead to cold solder joints, solder bridges, or insufficient solder. These defects can affect the functionality of the PCB. - Component Misalignment

Components may not be correctly aligned during insertion, leading to issues such as poor electrical contact or incorrect functionality. - Excessive Solder

Too much solder can cause short circuits between pads or leads, potentially leading to failure in the circuit.

By using proper techniques and regular inspection, these defects can be minimized.

What is the Through-Hole setup?

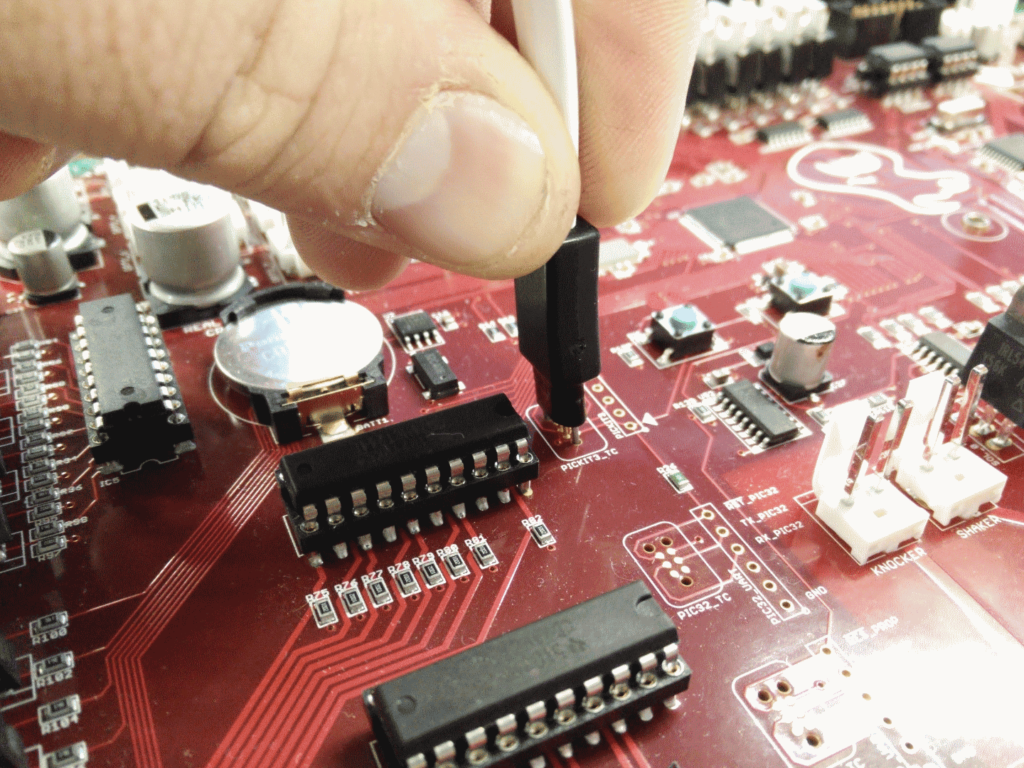

The Through-Hole setup involves inserting the components with leads into pre-drilled holes in the PCB. Proper alignment and soldering techniques are critical to avoid defects and ensure reliable connections.

The Key Processes in Through-Hole PCB Assembly

Through-Hole PCB assembly involves several key steps. Here’s an overview of the process:

- 1.Board Preparation

The PCB is cleaned to remove any contaminants or residue before assembly to ensure a clean surface for component insertion. - 2.Component Insertion

Components with leads are inserted into the pre-drilled holes. This is done manually or by automated machines in the case of larger production runs.

- 3.Wave Soldering

After component insertion, the board goes through a wave soldering process, where molten solder is used to form connections between the components’ leads and the PCB pads. - 4.Inspection and Testing

After soldering, the PCB is inspected for soldering defects and tested to ensure that all components are working properly and making the necessary connections.

Why Choose Unit Circuits As Your Partner?

When it comes to Through-Hole PCB assembly, Unit Circuits is the partner you can trust for high-quality results. Here’s why:

- Expertise and Quality Assurance

Unit Circuits has years of experience in Through-Hole PCB assembly. We use the latest technology and techniques to ensure that your project meets the highest quality standards. - Reliability

Our Through-Hole PCB assemblies are known for their durability and reliability, particularly in applications where the components need to withstand physical stress and harsh environments. - Fast Turnaround and Cost-Effectiveness

We offer quick turnaround times and competitive pricing, without compromising on quality, so you can get your products to market faster. - Comprehensive Support

From design consultation to final testing, Unit Circuits offers comprehensive services, providing all the support you need for a successful Through-Hole PCB assembly project.

CONNECT WITH US

Get A Instant Quote Today

Unit Circuits is your trusted partner for PCB fabrication, components sourcing, and PCB assembly. With over 7 years of experience, we have served 1000+ customers worldwide, delivering high-quality PCBs at competitive prices. Our company is ISO9001:2015 certified and UL listed, with all products undergoing E-testing, AOI, and X-RAY inspection to ensure they meet the highest standards. Get an instant quote today from our expert team, and we will handle the rest.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0