Quick Leads

What Is Through-Hole Technology (THT)? Benefits, Applications, and More

Quick Saying:

-

THT offers superior mechanical stability, ideal for high-stress environments.

-

Preferred for prototyping due to its ease of hand-soldering and testing.

-

Widely used in aerospace and industrial machinery for reliable performance.

-

THT vs. SMT: Understand the key differences and how to inspect THT components effectively.

What Is Through-Hole Technology (THT)?

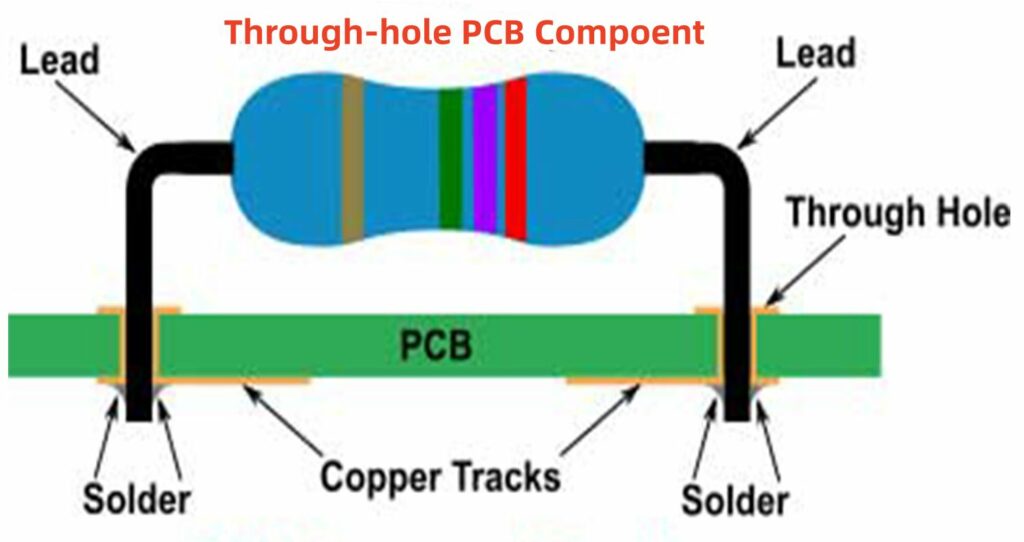

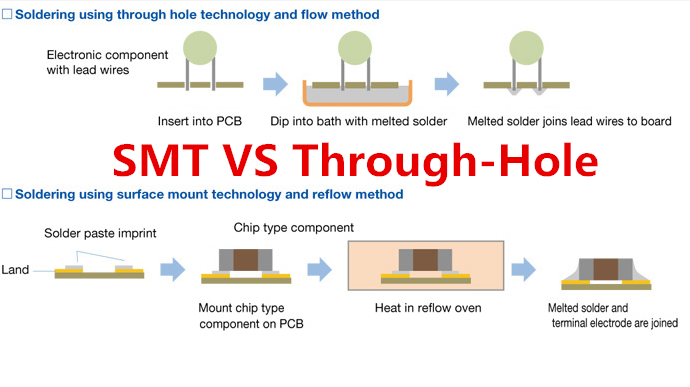

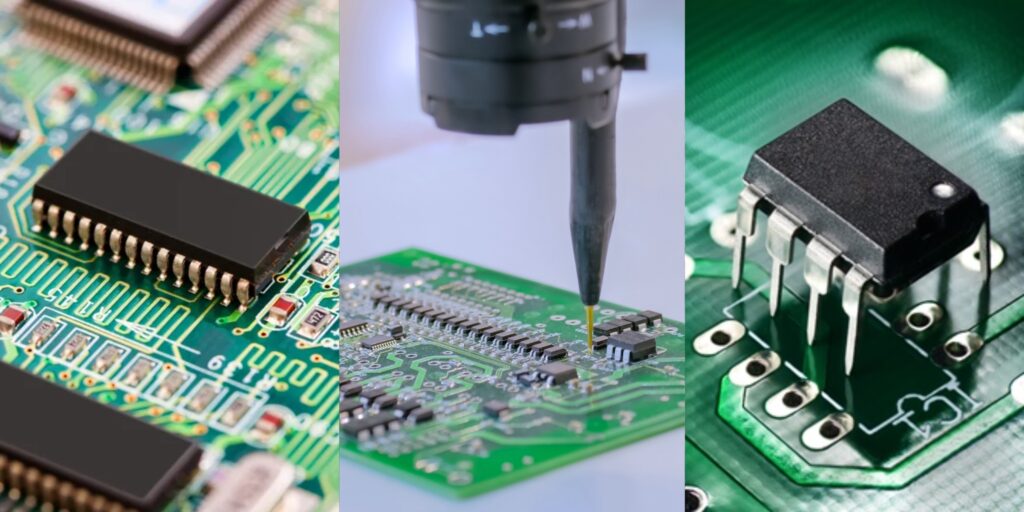

Through-hole technology (THT) is a method used in the assembly of electronic components, particularly in the manufacture of printed circuit boards (PCBs). With THT, you insert the leads of the components into drilled holes on a PCB and solder them onto pads on the other side. This process creates a strong mechanical connection, which makes it great for applications where the components need to withstand physical stress. You can do THT by hand or use automated machines. Each method has different levels of precision and efficiency.

How Does Through-Hole Technology Work?

Think of THT like planting seeds in a garden bed. Each seed (component lead) needs its own little hole (drilled space) to grow properly. Here’s a step-by-step look at the THT process:

- Drilling Holes: Precisely drilled holes are made in the PCB to fit the leads of different components.

- Component Placement: You insert components through these holes, either by hand or with automated THT machines.

- Soldering: You solder the leads onto the pads on the other side of the PCB. You can do this with wave soldering or by hand.

The result is a strong electrical and mechanical connection, which makes THT great for applications where reliability is really important, like industrial machinery and aerospace electronics.

Why Is Through-Hole Technology Still Relevant?

Even though Surface-Mount Technology (SMT) is really popular, THT is still really important in a lot of industries. That’s because THT components have a stronger physical bond to the PCB, so they’re good for environments that have a lot of vibrations or mechanical stress.

Things like automotive electronics, aerospace systems, and heavy industrial machinery use THT because it’s really tough.

What Are the Main Advantages of THT Over SMT?

Mechanical Strength (Advantage)

-

THT components are secured to the PCB, so they’re less likely to come loose when they’re under physical pressure or in high-temperature conditions. That’s why THT is the best choice for high-reliability applications.

Prototyping Ease (Advantage)

-

For engineers who are designing and testing new circuits, THT makes it really easy to make adjustments. You can take components out, put new ones in, or re-solder them when you’re prototyping. That’s why THT is great for small production runs.

Space Requirements (Disadvantage)

-

THT usually needs more space because you have to drill holes and the components are bigger. That’s why THT doesn’t work well for small devices like smartphones or wearables.

Best Applications for THT

Through-Hole Technology is especially valuable in the following fields:

- Aerospace and Defense: THT is mechanically reliable, so the components work even when they’re under a lot of stress or in really hot or cold temperatures.

- Industrial Machinery: For machines that vibrate a lot, THT is more durable than SMT.

- Prototyping and Testing: Engineers often use THT when they’re designing and testing because it’s easy to change components without hurting the PCB.

How Do You Inspect THT Solder Joints?

To make sure your THT assemblies are good quality, you have to inspect them carefully. Here are the main ways to do that:

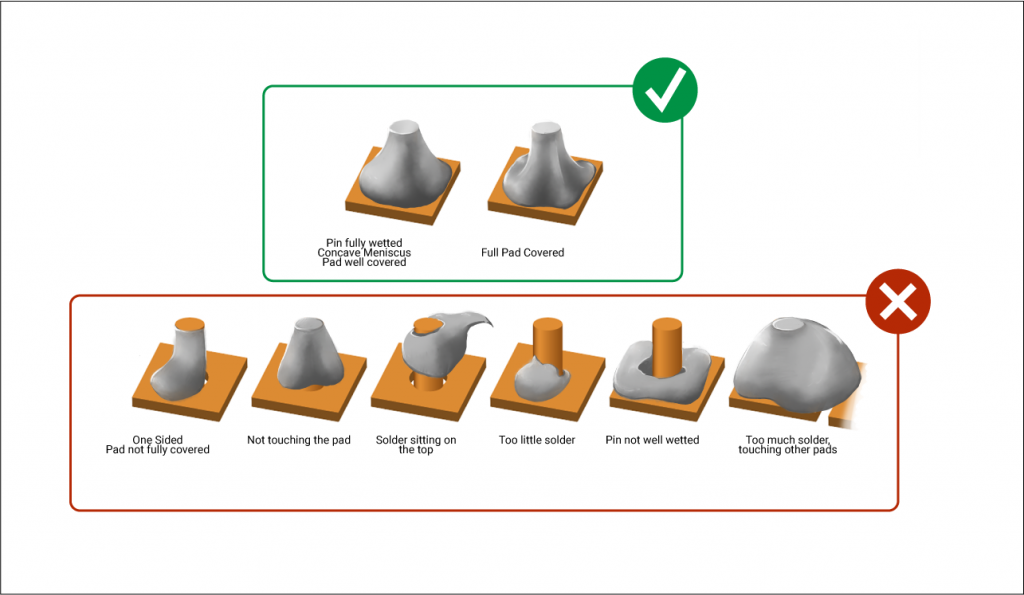

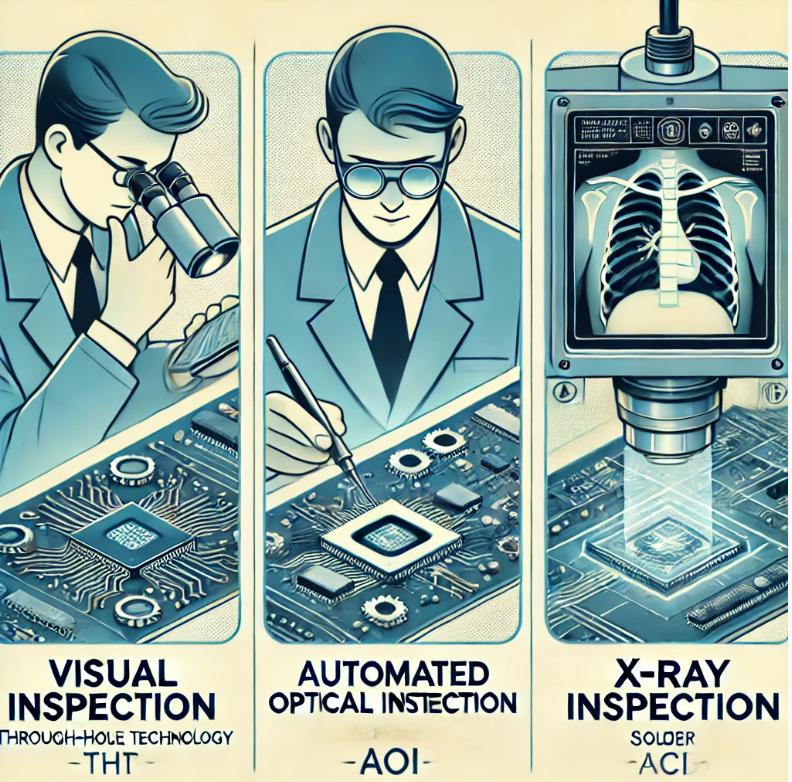

- Visual Inspection: You can look at the assembly and check for common problems like solder joints that aren’t complete, leads that aren’t lined up right, or cracks. This is usually the first way you find defects.

- Automated Optical Inspection (AOI): AOI systems use cameras to find problems like solder joints that aren’t good or components that aren’t lined up right. They’re really accurate and make inspection go faster.

- X-ray Inspection: This fancy way of doing it shows you problems inside the assembly, like solder joints that have holes in them or connections that aren’t good but you can’t see from the outside.

- Functional Testing: After you solder the THT components, you have to test them to make sure they work right in the circuit. You check to see if the electricity flows right and if they do what they’re supposed to do.

Future Trends in Through-Hole Technology

As industries evolve, so does THT. Here are some emerging trends:

- Hybrid Assemblies: A lot of manufacturers use both THT and SMT on the same PCB. They do this because SMT is small and THT is tough.

- Automated THT Systems: Automating THT has made it faster and cheaper and better quality.

- Focus on High-Reliability Applications: Because safety is so important in industries like aerospace and medical devices, THT is still really important. It’s the best way to make sure the connections are good.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverSummary and Conclusion

THT is still really important in electronics manufacturing. THT is great for applications where you need things to be really reliable because it’s tough and it’s easy to use when you’re prototyping. Even though Surface-Mount Technology is the most popular way to do electronics now, THT is still really important.

It’s the best way to make sure the connections are good in things like aerospace, industrial machinery, and other places where there’s a lot of stress. Knowing when and why to use THT can help you design electronics that work the way you want them to.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!