Quick Leads

What Are Castellated Holes on a PCB? Benefits, Manufacturing Process, and Applications

Introduction

When you design a PCB, the holes you use can make your design work better and make it faster to put together. One kind of hole is a castellated hole. They’re small, but they’re a big deal because they make it easy to connect PCBs together. Understanding their use, benefits, and how they are made can help you create more modular, compact, and efficient PCB designs. If you are looking for ways to improve your PCB assembly process or enhance your modular designs, castellated holes may be the answer. Let’s dive into what they are, why they are essential, and how to incorporate them into your projects.

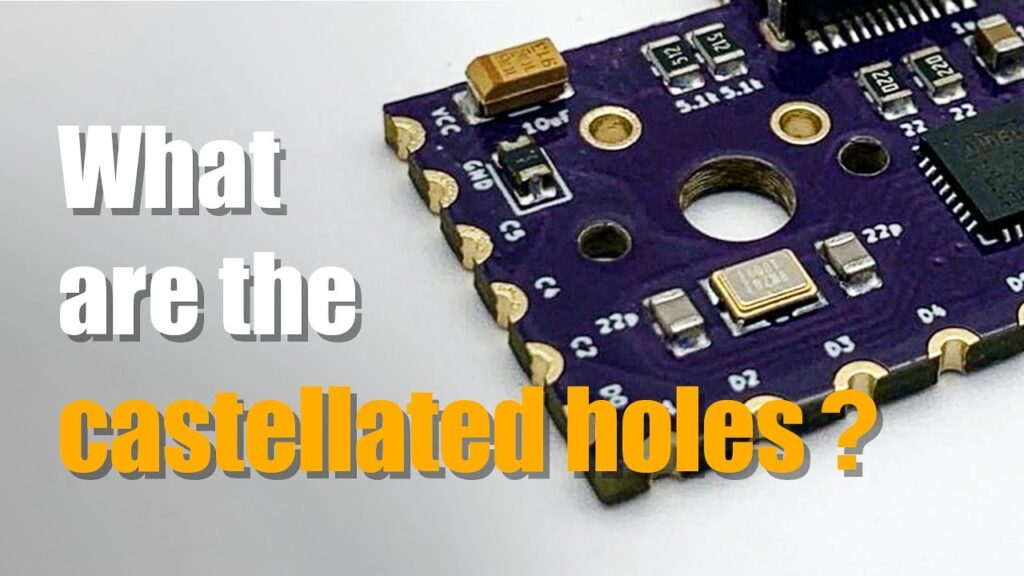

What Are Castellated Holes?

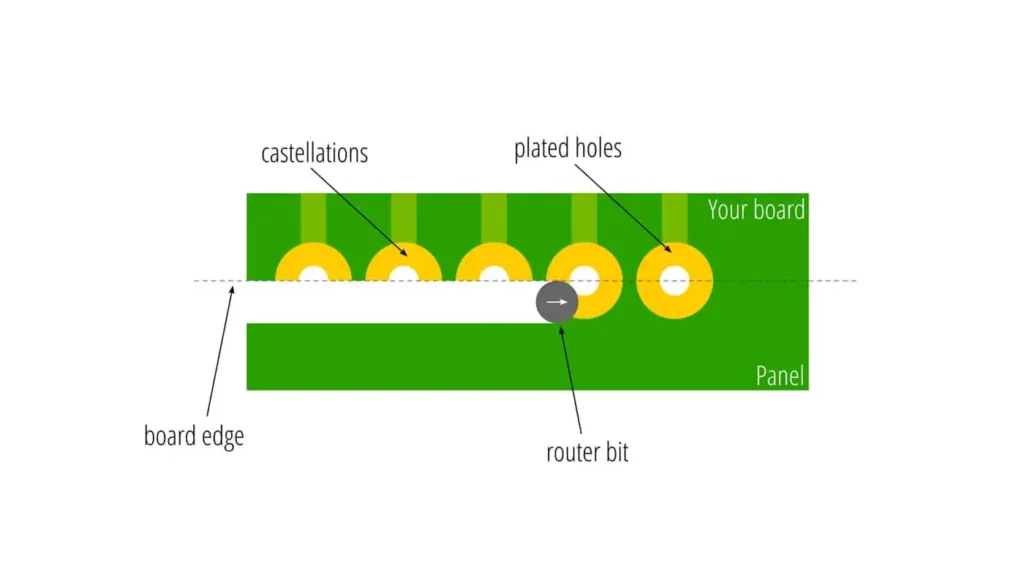

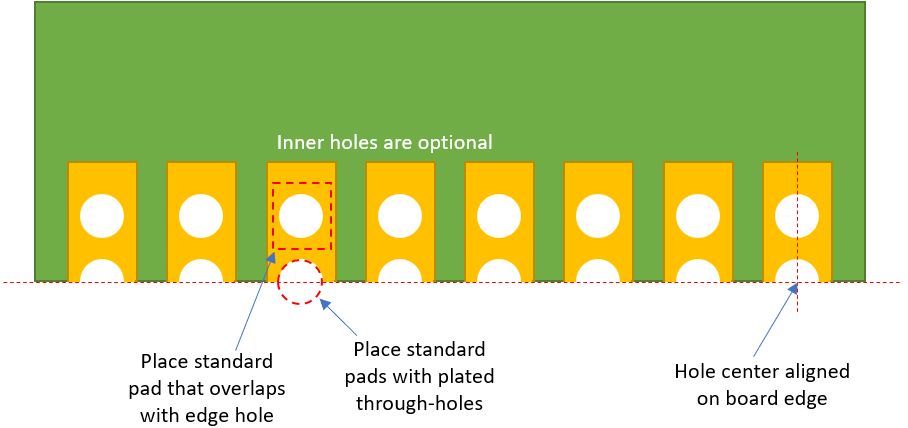

Castellated holes are partially drilled, semi-plated holes located along the edges of a PCB. These unique holes are formed by milling a plated through-hole (PTH) halfway, leaving part of the hole exposed on the surface. People use castellated holes to connect PCBs together. They’re used in modular PCBs, Wi-Fi modules, and breakout boards.

The primary purpose of castellated holes is to allow for simple board-to-board connections. If you put these holes around the edge of your PCB, you can stick another PCB on top of it. That way, you don’t need a connector, and you can make your whole system smaller and faster.

How Are Castellated Holes Made?

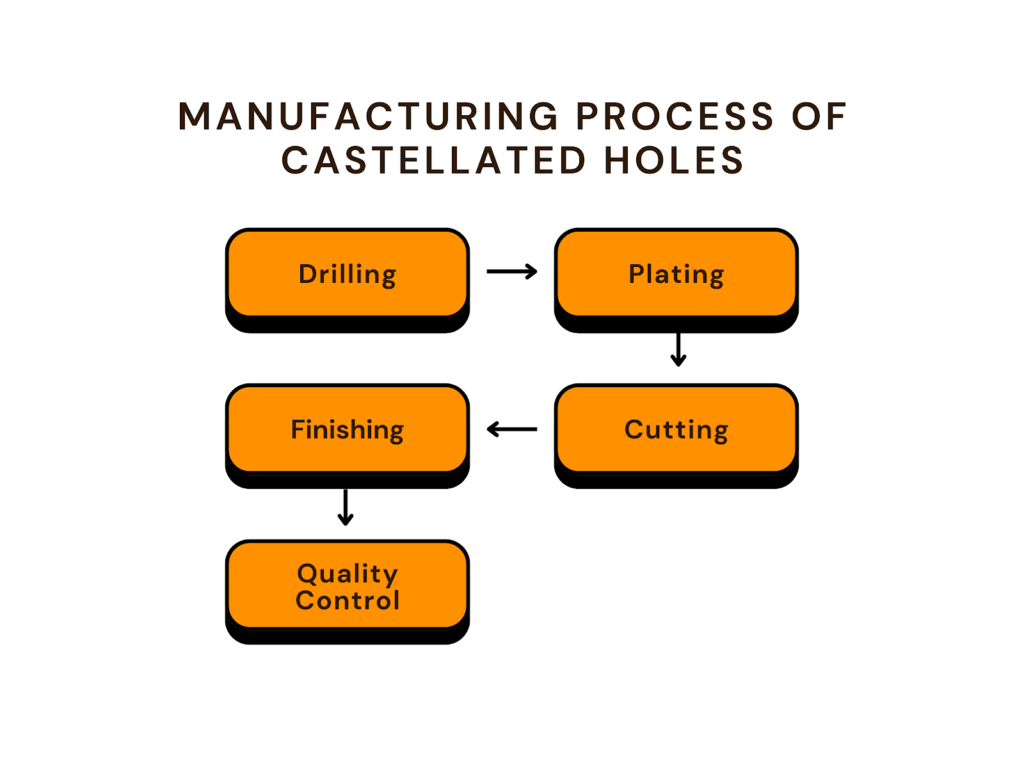

The manufacturing process for castellated holes involves several precise steps:

-

Drill the Through-Hole (PTH): Standard plated through-holes are drilled in the PCB.

-

Milling the Edge: A milling machine is used to cut the board’s edge, creating a partially exposed hole.

-

Plating: The exposed area is plated to ensure electrical conductivity.

-

Final Inspection: Quality control ensures the holes are properly formed and plated.

Making castellated holes is harder than making regular holes, so they cost more to make.

Benefits of Castellated Holes in Modular PCB Design

Castellated holes offer several advantages, particularly in modular PCB design:

-

Easy Board-to-Board Connections: Castellated holes make it easy to connect one PCB to another. They’re great for stacking PCBs or for sticking little boards on your big board, like sensors or wireless communication devices.

-

Space-Saving: Castellated holes let you get rid of connectors, so you can make your design smaller.

-

Cost-Effective in the Long Run: They cost more to make, but you can make your boards faster and you don’t need a connector, so they’re worth it.

-

Enhanced Mechanical Strength: The pads lock together, so your connection is good and strong, even if you shake it.

How Are Castellated Holes Different From Plated Through-Holes (PTH)?

Plated through-holes (PTH) and castellated holes are both plated and drilled, but they’re different because of where they are and what they do:

-

Plated Through-Holes (PTH): Through-holes are holes that go all the way through your PCB. They let you connect one layer to another.

-

Castellated Holes: Castellated holes are only drilled part of the way through your PCB. They’re on the edge of your board, so you can stick another board on top of it.

Castellated holes are essentially a specialized form of PTH, designed specifically for modular and compact designs, where space is at a premium.

Why Are Castellated Holes Expensive to Manufacture?

The cost of castellated holes primarily comes from the extra milling process required to create them. This process adds complexity, as it requires precise equipment and additional manufacturing time. Moreover, the plating inside the hole must be done carefully to ensure proper electrical conductivity.

Factors Contributing to the Cost:

-

Precision Milling: The edge milling requires accuracy, leading to higher production costs.

-

Material Waste: If you mill the edge of your PCB, you’re going to waste some material, and that costs more money.

-

Design Complexity: If you want to put castellated holes in your PCB, you have to think about it more and know what you’re doing. That’s going to cost you more money.

Use Cases of Castellated Holes in PCB Design

People use castellated holes when they want to connect PCBs together or make their PCBs smaller. Some common use cases include:

-

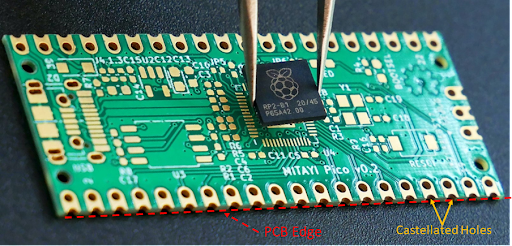

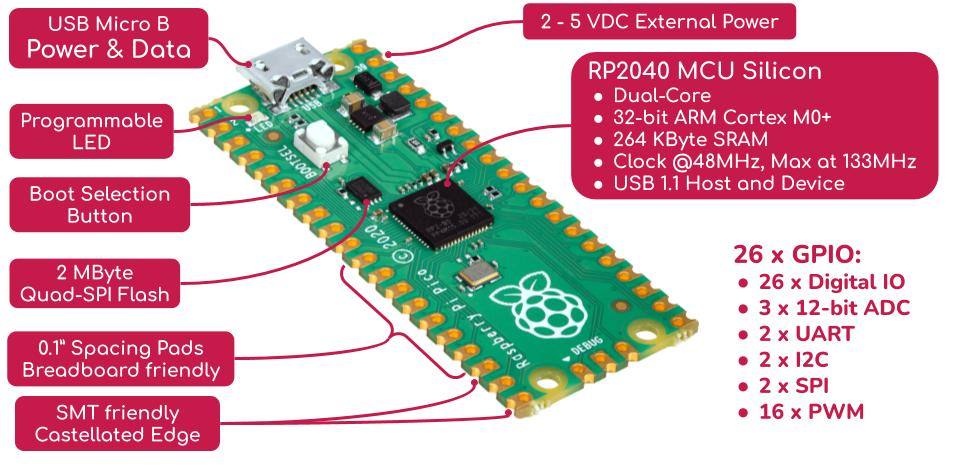

Raspberry Pi Breakout Boards: People use castellated holes to stick little boards on the Raspberry Pi. That way, you can stick sensors and other stuff on your Raspberry Pi.

-

Wireless Communication Modules: People use castellated holes for Wi-Fi, Bluetooth, and other communication modules. You can stick them on your main board.

-

IoT Devices: Many Internet of Things (IoT) devices use castellated holes for connecting smaller boards in a compact form factor.

These holes are ideal for designs where multiple PCBs need to be stacked or interconnected, and modularity is a key factor.

Steps to Manufacture Castellated Holes

Here is a quick overview of the steps involved in manufacturing castellated holes:

-

Create Standard PTHs: Begin by drilling the through-holes for the PTHs.

-

Mill the Edges: Mill the PCB edge to expose part of the hole, leaving a half-plated opening.

-

Plate the Hole: Plate the exposed hole to maintain electrical connectivity.

-

Final Inspection:Make sure your holes are the right size and in the right place so you can stick one board on top of the other.

Making castellated holes is harder than making regular holes, so it costs more money. But you can stick one board on top of the other, so it’s worth it.

What Is the Role of Castellated Holes in PCB Assembly?

Castellated holes simplify PCB assembly by providing a reliable edge-mount connection. They allow for easier attachment of one PCB to another without the need for traditional connectors. If you don’t have a lot of space or you want to stick a bunch of boards together, castellated holes are what you need.

Key Advantages:

-

Reduced Connector Size: Saves valuable space on the PCB by eliminating the need for connectors.

-

Improved Efficiency: Speeds up the assembly process by simplifying inter-board connections.

-

Stronger Joints: The edge-mounted holes provide a robust mechanical and electrical connection.

Final Thoughts: How to Use Castellated Holes in Your Design

If you use castellated holes in your PCBs, you can make them modular, save space, and make them faster. Whether you’re working on a custom electronics project, a Raspberry Pi add-on, or a multi-board system, understanding how to use castellated holes effectively will improve your design workflow.

Next Steps:

-

Evaluate Your Design Needs: If you’re working on a modular system, consider using castellated holes for board-to-board connections.

-

Consult with Manufacturers: Ensure your manufacturer supports castellated holes and can meet the required precision standards.

Engagement: Have you used castellated holes in your designs? Share your experiences and any tips in the comments below!

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Holes with castellations are super important for making small, modular PCBs that are easy to connect together. They cost more to make, but they let you get rid of connectors and save space, so they’re worth it. If you know what they’re good for, how to make them, and what they’re used for, you can make your PCBs better and make them faster.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!