Quick Leads

What Are the Best PCB Materials for High-Temperature Applications?

When you’re designing Printed Circuit Boards (PCBs) for high-temperature environments, it’s important to choose the right material for performance and reliability. Whether you’re working with automotive, aerospace, or industrial electronics, you need materials that can withstand extreme heat to ensure longevity and safety. But how do you know which PCB material is right for your needs?

Polyimide, High Tg, and ceramic substrates are some of the best PCB materials for high-temperature applications. These materials offer excellent thermal stability, mechanical strength, and electrical performance, making them ideal for industries such as aerospace, automotive, and military electronics. They can withstand temperatures up to 400°C, ensuring reliability in even the most extreme conditions.

Let’s dive into the properties of these materials a little more to help you choose the best one for your specific application.

What Are the Best Materials for High-Temperature PCBs?

Polyimide, High Tg, and ceramic substrates are the top choices for high-temperature PCBs. These materials have excellent thermal stability, which means your PCB will work well even in extreme heat. This is especially important for industries like aerospace, automotive, and military electronics, where reliability is key.

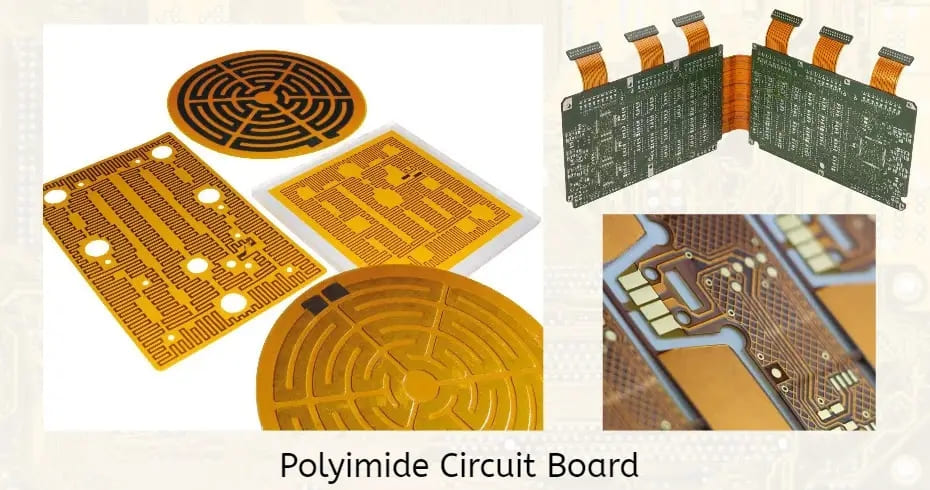

When Should You Use Polyimide PCBs in High-Temperature Environments?

Polyimide PCBs are perfect for extreme environments, as they can handle temperatures up to 400°C. Their excellent heat resistance makes them ideal for aerospace, military, and high-performance automotive applications. Polyimide’s ability to maintain mechanical integrity and electrical performance under fluctuating heat is crucial in mission-critical systems. For further reading on Polyimide PCBs, check out this from Unit Circuits.

What Makes High Tg PCBs a Good Choice for Heat Resistance?

High Tg PCBs are specifically designed to perform well in high-temperature environments.Their higher glass transition temperature (Tg) allows them to handle sustained heat better than standard FR-4 materials. These PCBs are commonly used in automotive, industrial, and power electronics where heat management is critical for system reliability.

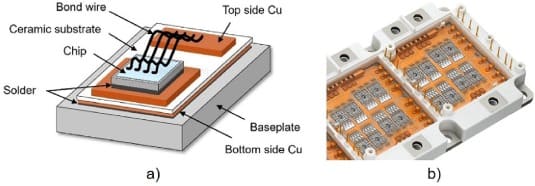

Why Are Ceramic Substrates Ideal for Power Electronics?

Ceramic substrates are a great option for power electronics due to their excellent thermal conductivity. They dissipate heat well, which is important for electronics that generate a lot of heat, like power supplies and electric vehicles. Their durability and ability to handle high temperatures make them a popular choice for high-power applications.

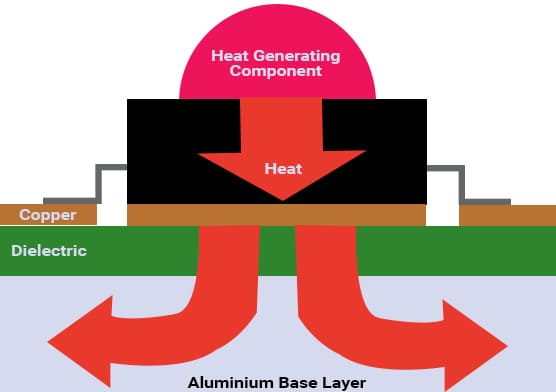

How Do Metal-Core PCBs Perform in High-Temperature Conditions?

Metal-core PCBs are designed to dissipate heat efficiently. These PCBs have a metal base layer, typically made of aluminum or copper, that provides excellent thermal conductivity. Metal-core PCBs are commonly used in high-power applications such as power supplies, LED lighting, and automotive electronics.

What Are the Benefits of Using Polyimide Over Other PCB Materials?

Polyimide is one of the best materials for high-temperature applications because it provides both thermal stability and flexibility. Unlike other materials, Polyimide doesn’t lose its mechanical strength even in extreme heat, which is why it’s the material of choice for industries like aerospace, automotive, and military electronics.

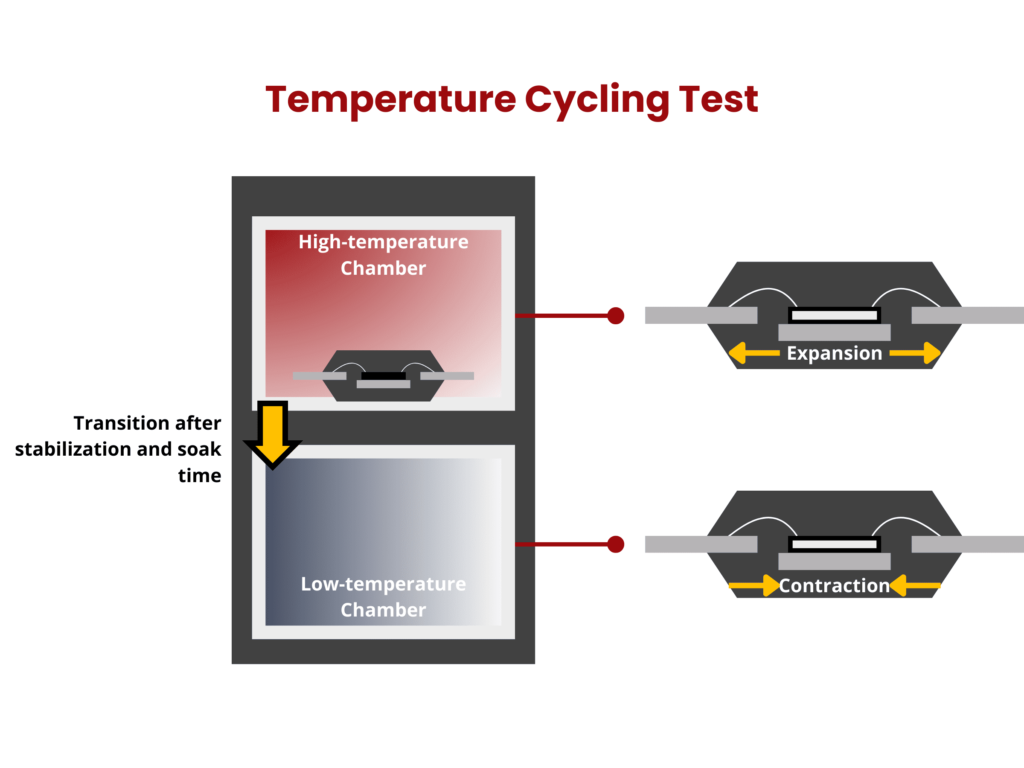

How Can I Test the Reliability of High-Temperature PCB Materials?

Reliability testing, such as thermal cycling, helps assess the material’s performance under extreme heat. This type of testing ensures that the material won’t fail when the temperature changes quickly, which is important in industries like aerospace, military, and automotive. Materials like Polyimide, High Tg, and ceramic substrates pass these tests, so you can count on them to work well in harsh conditions for a long time.

How to Choose the Right PCB Material for Automotive Electronics?

For automotive electronics, choose heat-resistant materials like High Tg and Polyimide PCBs. These materials hold up in the heat and are resistant to the harsh conditions found in cars, like extreme heat and vibration.

Polyimide PCBs: The Ultimate High-Temperature Solution

Polyimide is the industry standard for high-temperature PCBs, offering exceptional thermal stability. It can withstand temperatures up to 400°C, making it ideal for industries like aerospace, automotive, and military electronics. Polyimide PCBs also provide excellent mechanical strength and electrical performance under fluctuating or sustained heat.

- Thermal Stability: Retains flexibility and strength even in extreme temperatures.

- Performance: Performs reliably in high-heat applications.

- Ideal Applications: Aerospace, military, and high-performance automotive systems.

High Tg PCBs: Heat Resistance for Industrial Electronics

High Tg (glass transition) PCBs are specifically designed for high-temperature environments. Their higher glass transition temperature makes them ideal for use in applications where sustained heat is common, such as automotive systems and industrial electronics.

- Thermal Resistance: High Tg PCBs can tolerate higher operating temperatures.

- Mechanical Durability: Ideal for heavy-duty systems requiring long-term reliability.

- Applications: Industrial systems, automotive electronics, and power supply units.

Ceramic Substrates: Excellent for Power Electronics

Ceramic substrates are a great option for power electronics due to their outstanding thermal management properties. They provide efficient heat dissipation, which is essential for electronics that generate significant heat, such as power supplies and electric vehicles.

- Thermal Conductivity: Ceramic substrates help dissipate heat efficiently.

- Durability: Long-lasting performance under extreme conditions.

- Applications: Power electronics, high-voltage systems, and industrial machinery.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Knowing the best PCB materials for high-temperature applications can help you make smart choices when designing critical systems. Whether you’re in aerospace, automotive, or industrial electronics, materials like Polyimide, High Tg, and ceramic substrates offer the heat resistance needed to ensure long-term reliability and performance.

Ready to find the perfect high-temperature PCB material for your project? Contact our experts today for a free consultation and discover tailored solutions to meet your needs.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!