Quick Leads

What is a PCB Assembly E-Test Fixture?

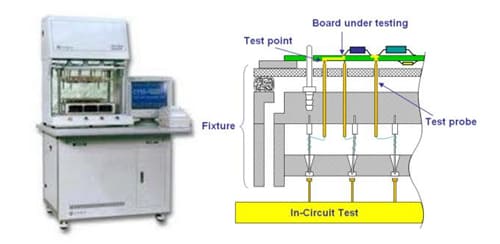

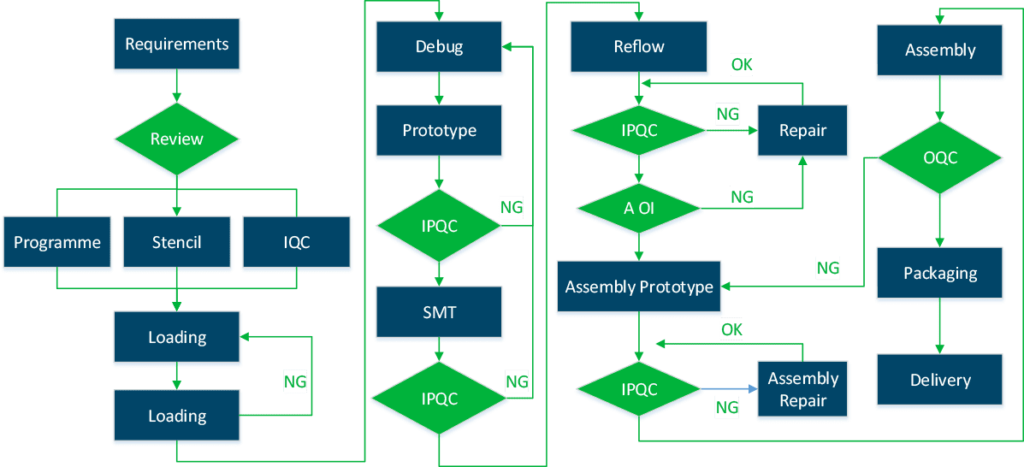

How Does a PCB Assembly E-Test Fixture Work? Step-by-Step Guide

-

Place the PCB on Fixture: Secure the board on the fixture, aligning it with the probes.

-

Activate Testing Signals: Start the test, applying calibrated low-voltage signals to detect issues.

-

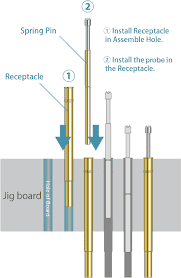

Probe Mechanics: Spring-loaded probes contact PCB test points, detecting electrical continuity, shorts, or open circuits.

-

Analyze and Adjust: Inspect test results for faults, addressing errors before final assembly.

The Role of Testing Signals and Probe Mechanics

-

Continuity Testing: Detects shorts or open circuits.

-

Resistance and Capacitance Measurements: Confirms specific parameters for complex boards.

Top Reasons PCB Testing is Essential for Quality Assurance

-

Cost Savings by Reducing Errors: Detecting issues early reduces costs related to rework and returns.

-

Compliance with IPC Standards: E-test fixtures help ensure compliance with standards like IPC-9252.

-

Enhanced Reliability: Testing minimizes the chance of field failures, boosting product reliability.

Why Choose E-Test Fixtures? Key Benefits Explained

-

Speed and Efficiency: Automated testing for high-volume production.

-

Consistency and Precision: Maintained probe calibration provides accurate readings.

-

Versatility: Capable of testing multiple parameters, enhancing quality control.

Avoiding Common PCB Testing Pitfalls with E-Test Fixtures

Maintenance Checklist

-

Daily: Inspect for debris and clean contact points.

-

Weekly: Calibrate probes to maintain contact accuracy.

-

Monthly: Check for wear on probes and fixture materials; replace if needed.

Troubleshooting Common Issues

-

Probe Misalignment: Realign or recalibrate probes if readings vary.

-

Fixture Wear: Replace worn contact points to ensure consistent quality.

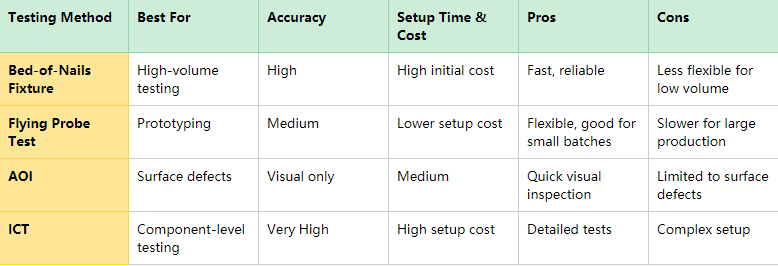

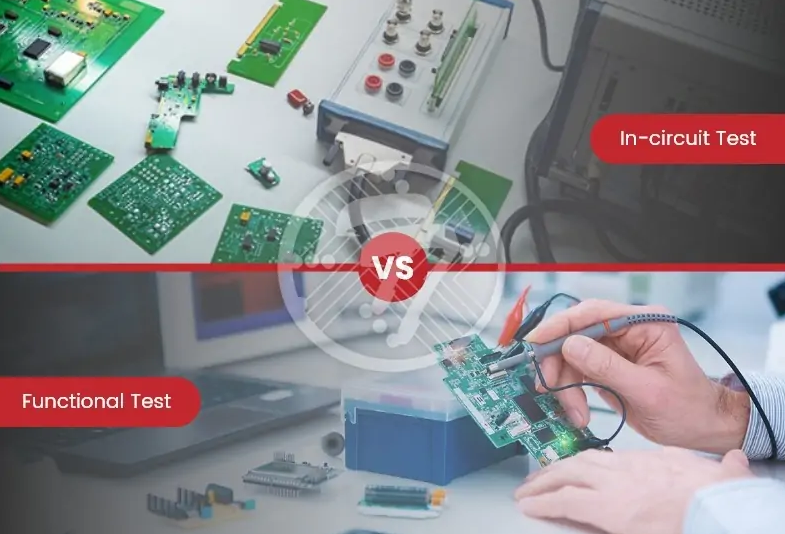

Comparison: E-Test Fixtures vs. Other Testing Methods

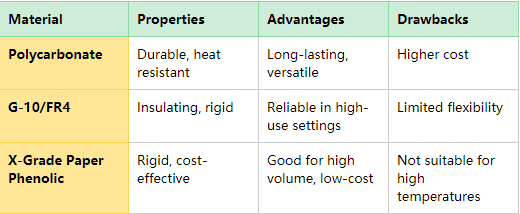

Materials Used in E-Test Fixtures and Their Benefits

Industry Applications and Future Technologies

Industry Applications

-

Automotive: Ensures reliability in critical components like ECUs and sensors.

-

Telecommunications: Validates high-frequency boards for devices requiring signal integrity.

Future Technologies

For more information, visit below:

Frequently Asked Questions (FAQs)

Generally, 3–5 years, depending on usage and maintenance.

Yes, many modern fixtures are designed to support high-frequency testing.

The cost of setting up can be different, but it’s usually a lot because you have to make it just for you, especially if you have a complicated board.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverKey Takeaways

-

E-Test Fixtures are Essential:These fixtures make sure that the quality of your PCBs stays the same, which is why they’re so important when you’re making a lot of them.

-

Maintenance is Crucial: If you take care of your fixtures and keep them tuned up, you can avoid a lot of problems and make them last longer.

-

Choosing the Right Test: If you know what’s good and bad about each way to test PCBs, you can pick the one that’s best for what you need.

Request for Quote

RECENT POSTS

Quick Turn Turnkey PCB Assembly: Fast Quotes, Faster Prototypes, Lower Risk

Quick turn turnkey PCB assembly for engineers who need fast quotes, reliable component sourcing, controlled SMT/DIP processes, and verified prototypes. Reduce risk, avoid platform pitfalls, and move from design to working boards faster.

IC Boards Explained: Applications, Layout Tips, and Assembly Services

Discover what IC boards are, how they’re used in modern electronics, and how to design them effectively. Learn layout tips and explore expert IC board assembly services for faster production.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!