Quick Leads

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

1. Introduction

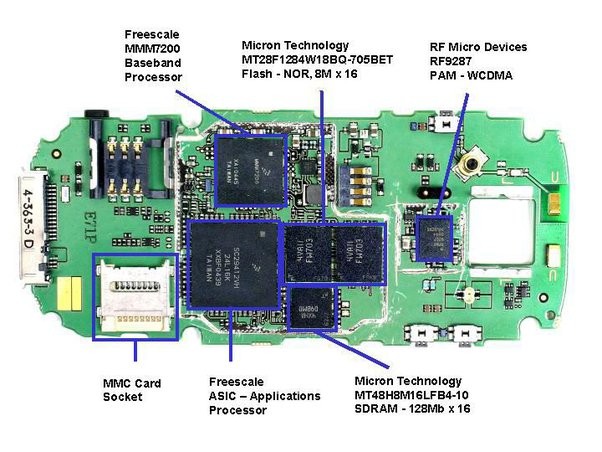

PCB Assembly (PCBA) is at the heart of modern electronics, transforming bare printed circuit boards (PCBs) into functional devices by attaching electronic components. This guide simplifies the basics of PCB Assembly for beginners, covering processes, tools, and key benefits.

2. What is PCB Assembly? A Beginner’s Guide

-

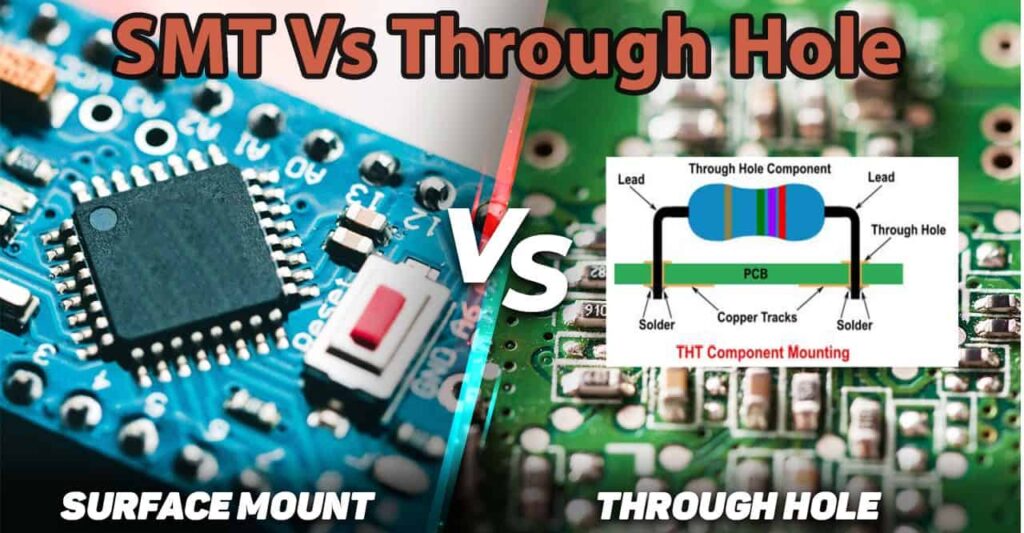

Surface Mount Technology (SMT): Components are mounted directly onto the PCB surface, ideal for compact designs.

-

Through-Hole Technology (THT): Components are inserted into holes on the PCB and soldered for secure connections, often used for robust applications.

-

Smartphones

-

Laptops

-

IoT devices

3. Key Steps in the PCB Assembly Process

-

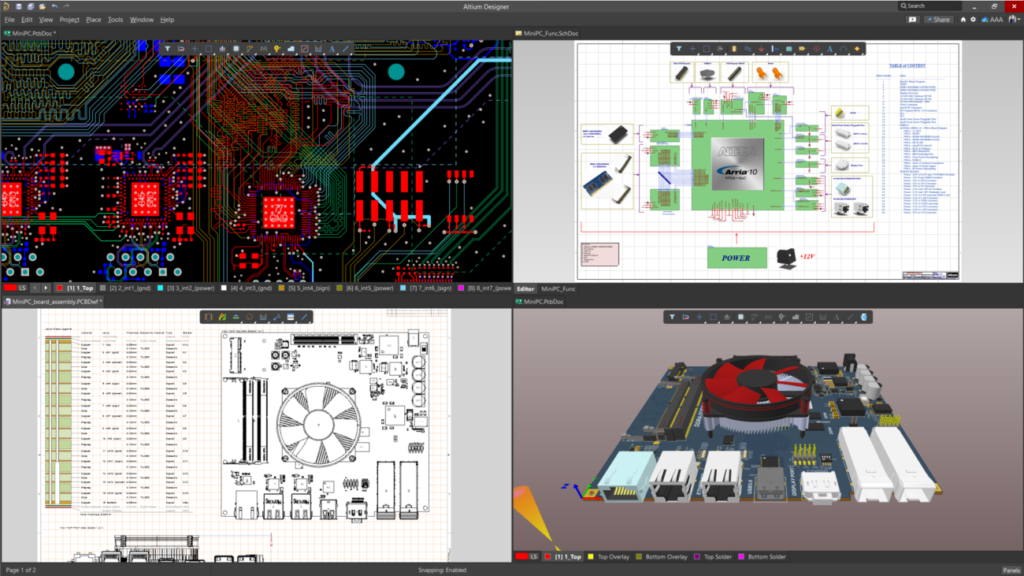

Use software like Altium Designer to create the PCB layout.

-

Procure components, including resistors, capacitors, and ICs, based on design specifications.

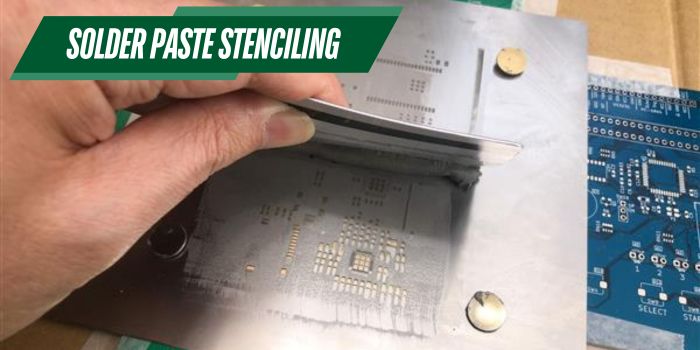

- A stencil applies solder paste to PCB pads for precise placement. Automated methods improve accuracy and efficiency.

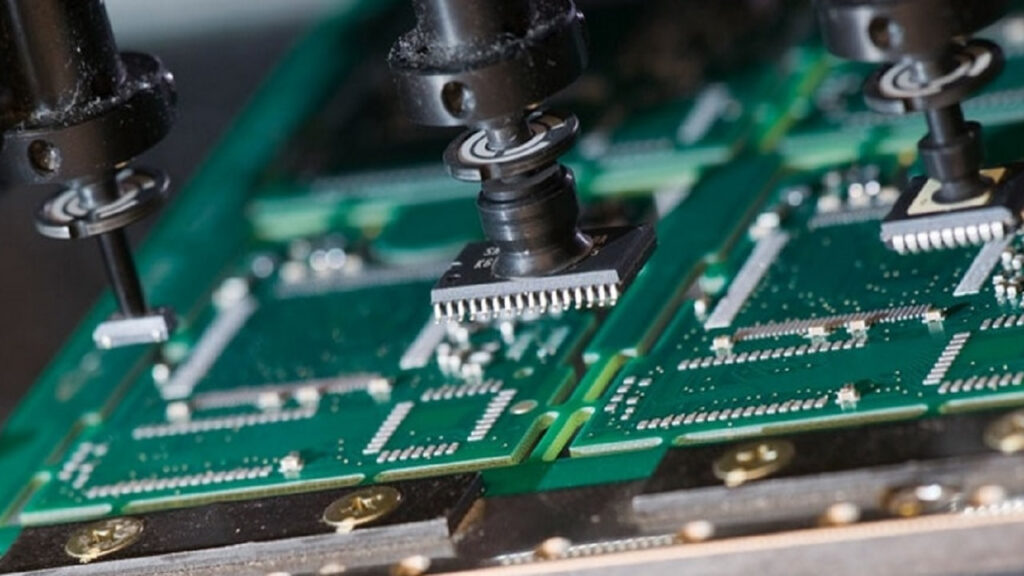

- Components are placed on the PCB using manual techniques or automated pick-and-place machines for speed and precision.

- Reflow Soldering (for SMT): A reflow oven melts the solder paste, securing components.

- Wave Soldering (for THT): A wave of molten solder attaches components inserted into the PCB holes.

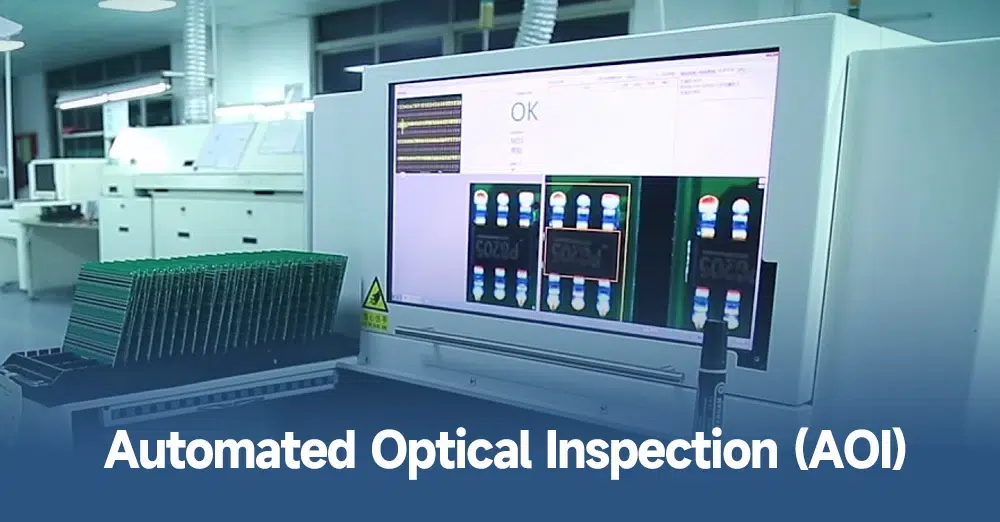

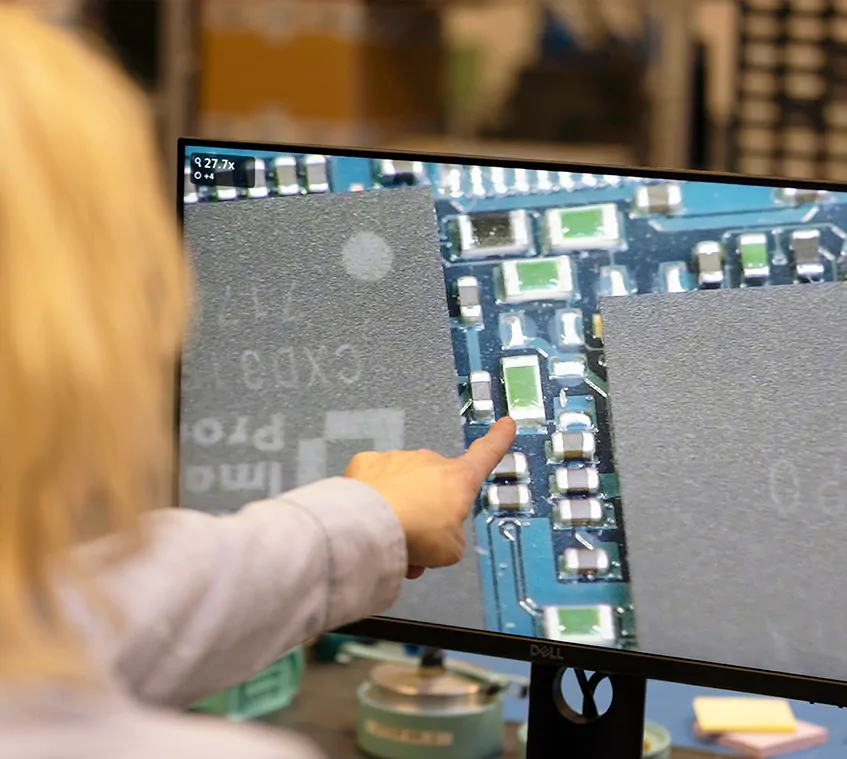

- Quality control methods include Automated Optical Inspection (AOI), X-ray inspection, and functional testing to ensure reliability.

- Multiple PCBs are assembled into a single device if required.

4. Popular PCB Types: Which One Fits Your Project?

-

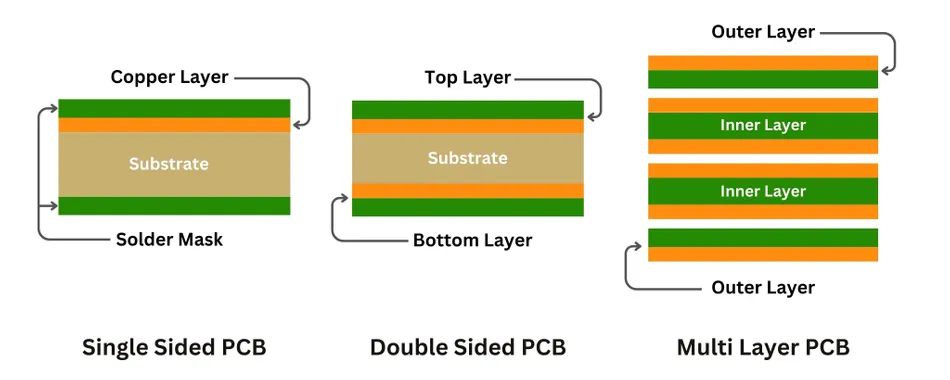

Single-Sided PCBs: Simple and cost-effective, great for beginner projects.

-

Double-Sided PCBs: Support components on both sides for more complex circuits.

-

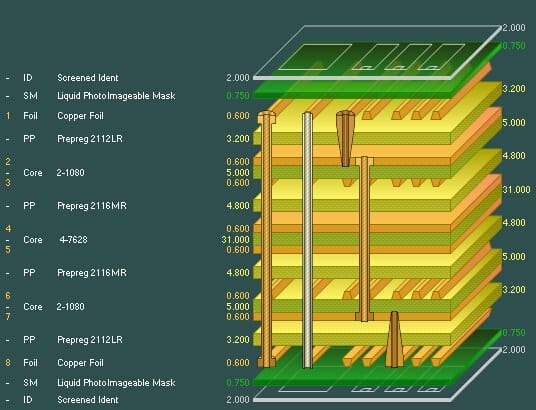

Multilayer PCBs: Ideal for advanced devices like smartphones and servers.

-

Rigid PCBs: Durable and widely used in standard devices.

-

Flexible and Rigid-Flex PCBs: Perfect for wearable technology and specialized applications.

5. PCB Assembly Tools for Beginners

-

Soldering Iron: For manual component soldering.

-

Multimeter: For testing circuit connections.

-

Tweezers: For placing small components precisely.

- Reflow Oven: Melts solder paste during SMT.

- Pick-and-Place Machine: Automates component placement.

- Stencil Printer: Ensures accurate solder paste application.

6. Benefits & Challenges of PCB Assembly

-

Compact designs enable smaller, more advanced devices.

-

High reliability ensures durable electronics.

-

Cost-efficient methods like SMT reduce production expenses.

- Complex multilayer designs require meticulous planning.

- Quality control is crucial to avoid costly malfunctions.

- Finding reliable components can be time-consuming.

7. Why Choose Professional PCB Assembly Services?

-

Expertise ensures accurate component placement and soldering.

-

Fast turnaround reduces time-to-market.

-

Thorough testing guarantees reliable products.

Frequently Asked Questions (FAQs)

PCB Assembly (PCBA) is the process of attaching electronic components to a PCB to create a functioning circuit.

SMT mounts components on the PCB surface, while THT involves inserting components into drilled holes.

Beginners need a soldering iron, multimeter, and tweezers. Advanced projects require reflow ovens and pick-and-place machines.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliver8. Conclusion

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!