Quick Leads

What is SMT Assembly? A Beginner's Guide to the Steps and Benefits of SMT

If you’re new to electronics manufacturing, getting your head around

Surface Mount Technology (SMT) assembly can feel like diving into a world of technical jargon. However, understanding SMT assembly is essential if you want to create modern, efficient electronic devices. In this guide, we’ll walk you through the basics, steps, and benefits of SMT assembly, simplifying it for beginners.

Surface Mount Technology (SMT) assembly can feel like diving into a world of technical jargon. However, understanding SMT assembly is essential if you want to create modern, efficient electronic devices. In this guide, we’ll walk you through the basics, steps, and benefits of SMT assembly, simplifying it for beginners.

Whether you’re a small business owner, a startup founder, or an engineer, this guide will give you actionable insights to optimize your electronics manufacturing process.

What is SMT Assembly?

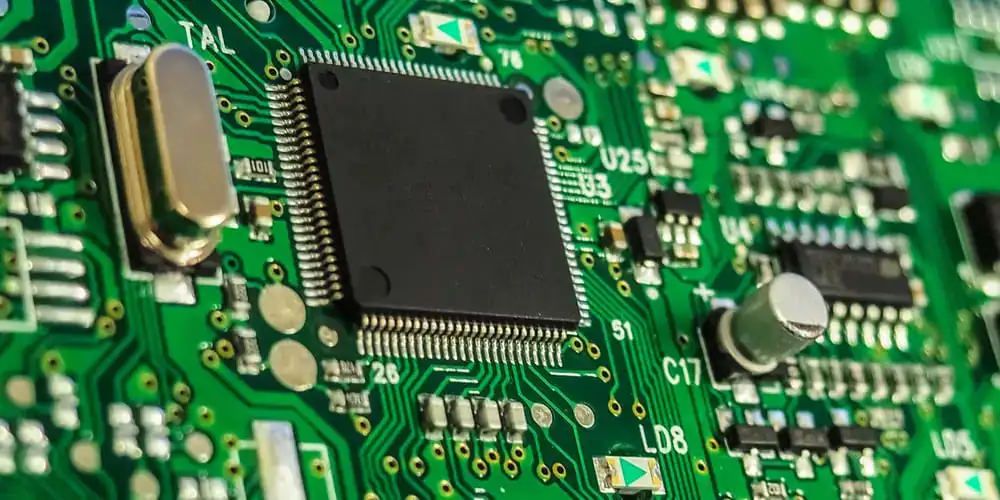

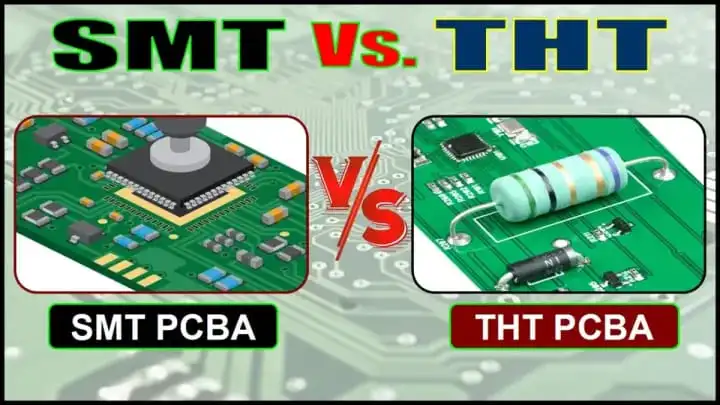

Surface Mount Technology (SMT) assembly is the process of mounting electronic components directly onto the surface of printed circuit boards (PCBs). This advanced technique eliminates the need for traditional through-hole technology (THT), which reduces manufacturing time and allows for smaller, lighter, and more efficient products.

What Does SMT Assembly Involve?

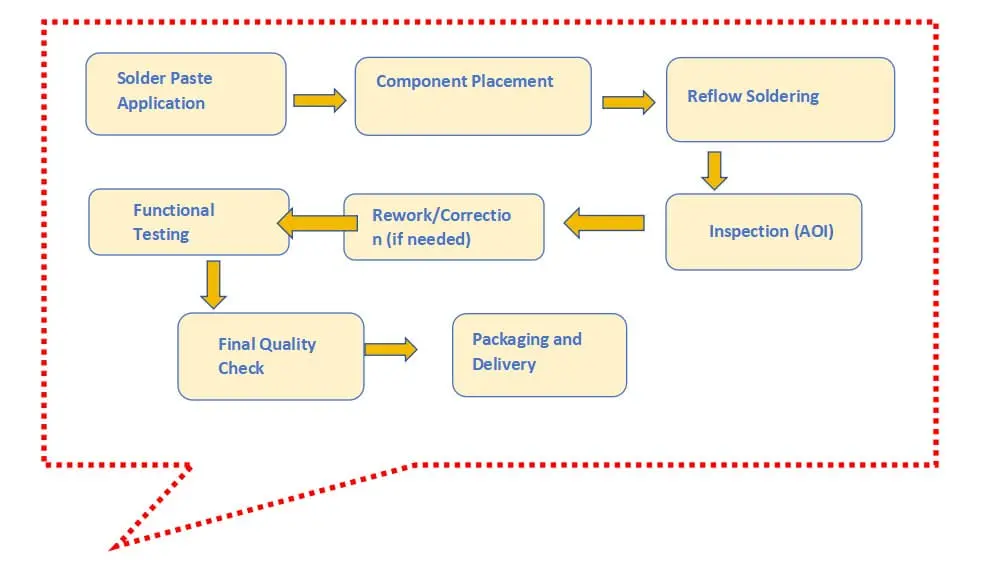

The SMT assembly process is a combination of precision, automation, and advanced technology. Here’s a quick overview of the main steps:

- Solder Paste Printing: A stencil is used to apply solder paste to the pads on the PCB.

- Solder Paste Inspection (SPI): Automated systems make sure the paste is applied correctly.

- Component Placement: Pick-and-place machines put the surface-mounted devices (SMDs) onto the PCB.

- Reflow Soldering: The PCB goes through a reflow oven, where the solder paste melts and connects the components.

- Automated Optical Inspection (AOI): Checks for alignment and soldering quality.

- Testing and Final Assembly: PCBs are tested for functionality and separated into individual boards for final use.

Why It Matters: Every step in the

SMT process is important to making sure you get high-quality, reliable electronic products.

SMT process is important to making sure you get high-quality, reliable electronic products.

How Do SMDs Differ from SMT?

While people often say SMD and SMT interchangeably, they’re not the same thing:

- SMD (Surface-Mounted Device): Refers to individual components like resistors and capacitors.

- SMT (Surface Mount Technology): Describes the overall process of mounting these components onto PCBs.

SMT vs. THT: What’s the Difference?

Before SMT, Through-Hole Technology (THT) was the standard for

PCB assembly. THT involves sticking component leads into drilled holes, which is slower and less efficient.

PCB assembly. THT involves sticking component leads into drilled holes, which is slower and less efficient.

Feature | SMT | THT |

Component Size | Compact, for small devices | Larger, for industrial use |

Production Speed | High, with automation | Slower, mostly manual |

Cost Efficiency | Lower production costs | Higher due to additional steps |

Applications | Consumer electronics, IoT | Aerospace, high-stress circuits |

What Equipment is Used in SMT Assembly?

Today’s SMT assembly relies on advanced machines to make sure everything is precise and efficient:

- Stencil Printers: Apply solder paste with high accuracy.

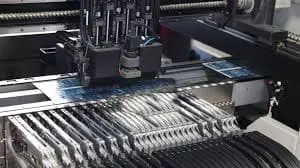

- Pick-and-Place Machines: Position components rapidly and precisely.

- Reflow Ovens: Heat PCBs to melt solder and bond components.

- Inspection Systems (AOI/SPI): Check alignment and solder quality.

When manufacturers invest in the best equipment, they can reduce mistakes and get the most out of their production.

Benefits of SMT Assembly

SMT assembly has a ton of benefits, which is why it’s the way everyone makes electronics today:

- Space Efficiency: Perfect for compact devices like smartphones and wearables.

- Scalability: Adapts easily to both prototype and high-volume production.

- High Reliability: Automated systems ensure consistency and precision.

Common Challenges in SMT Assembly (and How to Solve Them)

Despite its benefits, SMT assembly isn’t without challenges. Here are some common issues and their solutions:

Challenge | Solution |

Solder Bridging | Use precise stencil designs and controlled paste volume. |

Component Misalignment | Regularly calibrate pick-and-place machines. |

Inspection Errors | Invest in advanced AOI and SPI systems. |

For more information, visit below:

For more insights on Complete Guide on it, check out:

What is SMT Assembly?

Frequently Asked Questions (FAQs)

SMT lets you make things faster, cheaper, and smaller, which is perfect for the stuff we make today.

Industries like consumer electronics, automotive, healthcare, and aerospace use SMT to make their high-performance products.

If you keep your equipment in good shape, make sure your stencil is right, and check your work, you can avoid problems like solder bridges and parts that aren’t lined up right.

When you’re prototyping, you make a few boards and look at them to see if they work. You make changes and try again until you get it right.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverCall to Action

Are you ready to make your electronics better? Check out our SMT assembly services and see how we can help you make your stuff. Get a free quote today and save 20% on your first project!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!