Quick Leads

Why SMT is a Game-Changer in Modern Electronics

In today’s fast-paced electronics industry, cost-efficient PCB manufacturing, high-speed assembly, and compact circuit designs are key drivers of success. Surface-Mount Technology (SMT) in PCB assembly has emerged as a crucial solution for these challenges, offering significant advantages over traditional methods like Through-Hole Technology (THT) for PCB production.

Whether you’re an electronics engineer designing PCBs, a decision-maker evaluating SMT vs THT for manufacturing, or a business owner looking for reliable SMT PCB assembly services, understanding the benefits of SMT can give you the edge needed to stay competitive.

What is SMT in PCB assembly, and why is it the preferred choice for modern electronics manufacturing?

✅ SMT allows for smaller, high-density PCB designs, making it ideal for consumer electronics, automotive PCBs, and IoT devices.

✅ Automated SMT assembly processes reduce labor costs, ensuring faster production cycles and consistent quality.

✅ Compared to through-hole technology, SMT components are more cost-effective and suitable for high-volume PCB manufacturing.

With SMT PCB prototyping and mass production, manufacturers can produce high-reliability circuit boards for industrial applications, medical devices, and telecommunications. If you’re exploring low-cost SMT PCB assembly services with quick turnaround times, SMT offers an optimized solution that meets the demands of modern technology.

Why SMT Is Crucial for PCB Manufacturing

Surface-Mount Technology (SMT) in PCB manufacturing has fundamentally transformed the industry by enabling smaller PCB designs, lightweight circuit boards, and high-reliability electronic components. With the increasing demand for miniaturized electronic devices, SMT PCB assembly services allow manufacturers to pack more components into compact PCBs, improving performance, durability, and heat dissipation.

Unlike Through-Hole Technology (THT) in PCB assembly, SMT production lines support fully automated PCB assembly, which enhances efficiency and reduces errors. This makes SMT ideal for high-volume PCB manufacturing, low-cost PCB prototyping, and rapid PCB assembly services. Additionally, SMT circuit board assembly significantly shortens production cycles, making it a cost-effective PCB manufacturing solution for companies aiming to optimize their electronics production processes.

What Are the Major Advantages of SMT?

1. Compact Size and High Component Density

SMT PCB assembly technology allows manufacturers to place components directly onto the surface of a printed circuit board (PCB) without the need for drilled holes. This enables high-density PCB designs, resulting in smaller, lightweight circuit boards that maximize space efficiency. Compared to through-hole PCB assembly, SMT allows for miniaturized electronic circuits, making it essential for advanced consumer electronics, automotive PCBs, and IoT device manufacturing.

2. Cost Efficiency and Automated Assembly

The automation of SMT PCB manufacturing leads to faster production cycles, reduced labor costs, and improved yield rates. SMT assembly costs are typically lower than through-hole PCB assembly costs due to the streamlined process and reduced manual labor requirements. Advanced SMT pick-and-place machines precisely position components, while automated reflow soldering in SMT production ensures strong and reliable connections. This makes low-cost SMT PCB assembly services an ideal choice for high-volume electronics production.

3. Enhanced Reliability

SMT-mounted components are more durable and resistant to mechanical stress, vibration, and temperature fluctuations compared to through-hole PCB components. These advantages make SMT circuit board assembly the preferred choice for automotive electronic systems, industrial control boards, and medical device PCBs, where high-reliability PCB assembly is critical.

👉 For more details on PCB assembly cost, check our PCB Assembly Services page to explore affordable and high-quality SMT solutions.

SMT vs THT: Understanding the Differences in PCB Assembly

When choosing between Surface Mount Technology (SMT) and Through-Hole Technology (THT) in PCB assembly, it’s important to understand their distinct PCB manufacturing processes and applications.

✅ SMT PCB assembly involves placing components directly on the PCB surface, enabling high-density PCB designs, smaller circuit boards, and automated assembly. This method is faster, more cost-effective, and ideal for high-volume PCB manufacturing, particularly in consumer electronics, automotive applications, and industrial control systems.

✅ THT PCB assembly requires inserting components into pre-drilled holes on the circuit board, creating stronger mechanical connections. This process is preferred for high-power components, aerospace PCBs, and applications requiring extreme durability. However, through-hole PCB assembly takes longer production time and is less suitable for miniaturized electronic devices.

Benefits of SMT & THT in PCB Manufacturing

🔹 Combining SMT & THT in PCB Assembly: In hybrid PCB manufacturing, both SMT and through-hole PCB assembly are used together—SMT for smaller, surface-mounted components and THT for larger, high-power electronic components.

🔹 SMT Assembly vs Traditional Through-Hole Technology:

- SMT PCB production is faster, cost-efficient, and enables compact designs, making it ideal for IoT devices, smartphones, and medical electronics.

- THT PCB soldering provides superior mechanical strength, making it suitable for mission-critical applications like automotive and aerospace electronics.

👉 Want a detailed comparison? Check our Comprehensive Guide on PCB Assembly Processes for expert insights into SMT vs THT manufacturing.

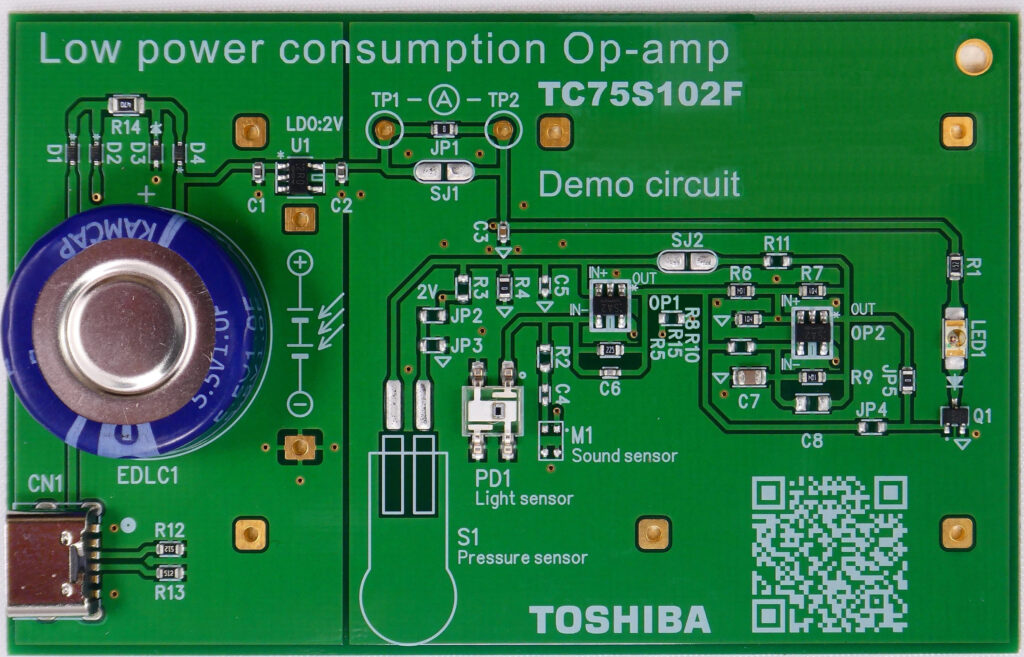

Understanding SMD Components: Identification, Sizes, and Usage

In Surface-Mount Technology (SMT) PCB assembly, Surface-Mount Devices (SMD components) are widely used due to their compact size, lightweight design, and high component density. Some of the most common SMD electronic components include SMD resistors, capacitors, diodes, and LEDs, which play a critical role in modern PCB manufacturing for consumer electronics, industrial automation, and automotive circuits.

These components come in standardized SMD package sizes, and an SMD size chart helps engineers and manufacturers select the correct parts based on circuit board layout, power requirements, and space constraints. Proper SMD component identification ensures precise placement and soldering in automated SMT production lines, reducing assembly defects and improving overall reliability.

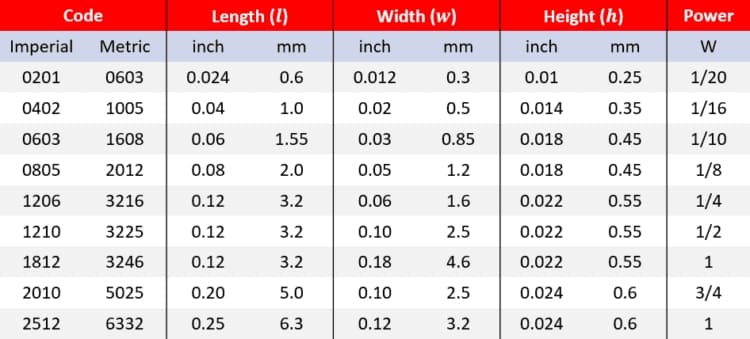

Understanding SMD Resistor Sizes

SMD resistor sizes follow industry-standard dimensions, such as 0201, 0402, 0603, 0805, and 1206, each offering different power ratings, resistance values, and voltage tolerances. Selecting the appropriate SMD resistor package is essential for ensuring optimal circuit performance, power efficiency, and heat dissipation in PCB designs for IoT devices, wearable technology, and power electronics.

👉 For a detailed guide on SMD component identification, check out our SMD Components Identification Guide.

How to Optimize PCB Assembly Costs with SMT

One of the biggest advantages of SMT PCB assembly is its cost-effectiveness, especially for large-scale PCB production and high-volume electronics manufacturing. The automated SMT assembly process reduces manual labor costs, minimizes production errors, and accelerates manufacturing timelines, making it a preferred choice for mass electronics production.

PCB Assembly Line Cost: Factors to Consider

When selecting an SMT PCB assembly service, the total PCB assembly cost depends on several key factors:

✅ PCB Design Complexity – Multi-layer PCBs with fine-pitch SMD components or BGA (Ball Grid Array) packages may require more advanced manufacturing techniques.

✅ Production Volume – Bulk PCB assembly orders typically offer lower per-unit costs due to economies of scale.

✅ Component Type & Sourcing – The cost varies between SMD components vs. through-hole components (THT), passive vs. active components, and custom vs. standard components.

✅ Manufacturing Location – PCB assembly in China generally provides lower labor and material costs, while PCB assembly in the USA or Europe may offer faster lead times and localized support.

PCB Assembly Service Pricing: China vs. USA

When sourcing PCB assembly services, it’s crucial to compare pricing across different regions. PCB assembly in China is known for affordable PCB manufacturing, large-scale production capacity, and cost-effective sourcing of SMD components. In contrast, PCB assembly in the USA offers higher labor costs but benefits such as faster turnaround times, local customer support, and compliance with strict industry regulations.

For businesses looking for cost-effective PCB assembly solutions, outsourcing SMT PCB manufacturing to China can significantly reduce production expenses while maintaining quality standards. However, factors such as shipping costs, import duties, and supply chain reliability should also be considered when choosing between domestic vs offshore PCB assembly.

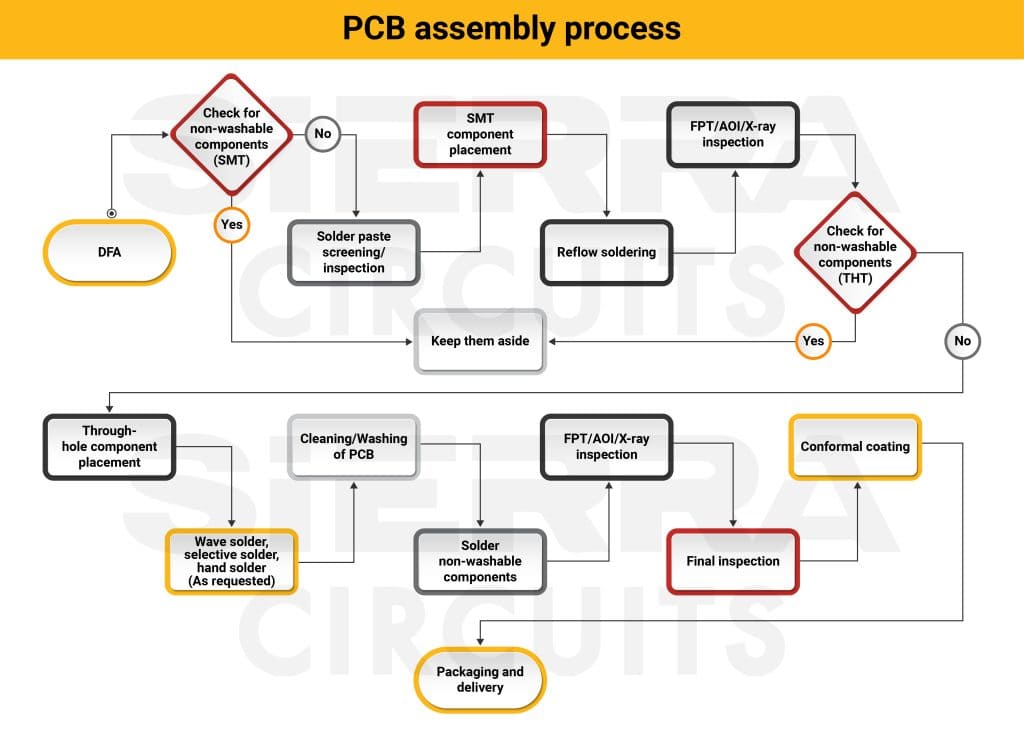

SMT Assembly Line Process Flow: A Step-by-Step Overview

The Surface-Mount Technology (SMT) assembly process follows a precise SMT production workflow to ensure high-quality PCB manufacturing. The key stages include:

✅ PCB Design & Layout Optimization – The PCB design phase focuses on optimizing for SMT PCB assembly, minimizing the need for through-hole (THT) components while ensuring proper trace routing, pad alignment, and solder mask application.

✅ SMD Component Placement – Using high-speed SMT pick-and-place machines, Surface-Mount Device (SMD) components are accurately placed onto pre-applied solder paste on the PCB surface. This step is crucial for ensuring precision in high-density PCB designs.

✅ Reflow Soldering Process – The PCB is then passed through a controlled temperature reflow soldering oven, where the solder paste melts and creates secure electrical connections. For double-sided SMT PCB assembly, this process is repeated for both sides.

✅ PCB Assembly Inspection & Quality Control – After soldering, automated optical inspection (AOI) in SMT assembly is conducted to check for misaligned components, solder defects, and missing parts. In high-reliability applications, X-ray inspection for BGA components may also be performed.

What to Expect from PCB Assembly and Testing Services

Once the SMT PCB assembly process is complete, the next critical stage is PCB testing and quality verification. The PCB testing process in electronics manufacturing ensures that every assembled board meets functional, electrical, and mechanical reliability standards before being shipped to customers.

Common PCB assembly testing methods include:

✅ In-Circuit Testing (ICT) for PCB assembly – Used to check for open circuits, short circuits, and incorrect component placements.

✅ Automated Optical Inspection (AOI) for SMT boards – Detects soldering defects, missing components, and alignment issues.

✅ X-ray Inspection for SMT PCB Manufacturing – Essential for ball grid array (BGA) components, microvias, and hidden solder joints.

✅ Functional PCB Testing (FCT) – Simulates real-world operating conditions to ensure the circuit performs as intended.

For manufacturers sourcing turnkey PCB assembly services, comprehensive PCB testing and inspection is a vital step in ensuring product reliability, minimizing defects, and improving overall yield rates.

👉 Interested in high-reliability SMT PCB assembly? Check our PCB Assembly Testing & Quality Control Guide for detailed insights.

Frequently Asked Questions

The SMT assembly process involves placing SMD components onto the surface of a PCB without the need for drilled holes. This method utilizes automated machinery, such as SMT machines, to place components like resistors, capacitors, and microchips with high precision. The components are then soldered using solder paste and reflow soldering. The result is a SMT PCB assembly that is compact, efficient, and cost-effective, especially suitable for high-volume production.

SMD resistor sizes are standardized, with common sizes like 0201, 0402, 0603, and 0805. These sizes refer to the physical dimensions of the resistor. For example, 0402 represents a component size of 0.04 inches by 0.02 inches. Smaller SMD resistors are typically used for compact PCB assemblies, such as in consumer electronics or wearables, where space is limited. The right SMD resistor size depends on the application’s power requirements and available space on the PCB board.

SMT and THT are two different technologies used in PCB assembly. SMT (Surface-Mount Technology) places components directly onto the surface of the PCB without holes, while Through-Hole Technology (THT) involves inserting leads through drilled holes. SMT is typically faster, more cost-efficient, and supports smaller components with higher component density, making it ideal for high-volume PCB manufacturing. On the other hand, THT provides stronger mechanical connections, ideal for components that experience higher stress, like in power supplies.

PCB assembly in China is often more cost-effective than in the USA or Germany due to lower labor costs, a well-established supply chain, and economies of scale. China’s dominance in PCB manufacturing makes it easier to access a range of services, from SMT assembly lines to SMD components. PCB assembly manufacturers in China also benefit from advanced technologies like flex PCB SMT assembly, which further reduces production costs. However, it’s important to consider factors like shipping time and quality control when sourcing overseas.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion: Embrace SMT for Cost-Effective and Efficient PCB Manufacturing

In conclusion, Surface-Mount Technology (SMT) in PCB assembly provides cost savings, improved production efficiency, and enhanced electronic performance. Whether you’re an electronics engineer designing SMT PCB layouts or a business owner sourcing turnkey PCB assembly services, adopting SMT PCB manufacturing solutions can streamline your production workflow and reduce PCB assembly costs.

With its automated SMT production lines, miniaturized SMD components, and reduced labor requirements, SMT circuit board assembly enables high-volume PCB manufacturing at competitive prices. For businesses looking to scale electronics production, choosing between SMT vs THT assembly is crucial in achieving optimal cost-performance balance.

👉 Ready to optimize your PCB assembly process? Explore our PCB Assembly Services for customized SMT solutions, competitive pricing, and fast turnaround times!

For more on PCB manufacturing services and detailed quotes, take a look at our page on PCB Assembly Services.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!