Quick Leads

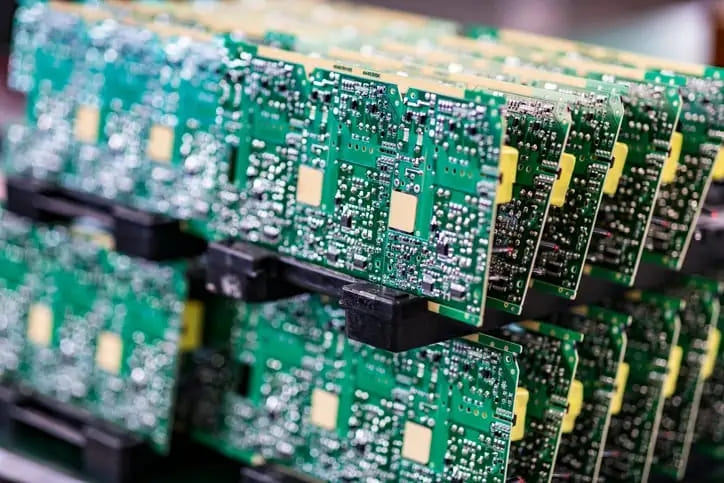

Why Is PCB Assembly So Expensive? (And How to Optimize Costs)

Introduction

If you’ve been wondering, “Why does PCB assembly cost so much?” you’re not alone. Whether you’re a startup trying to bring a product to market or an established company looking to scale, the costs of PCB boards can feel overwhelming—especially when they take a big bite out of your budget.

But here’s the thing—understanding what drives up the PCB board price can help you make better decisions and significantly reduce costs without sacrificing quality.

In this guide, I’ll break down the main factors contributing to the high price of PCB assembly manufacturing, share actionable tips to optimize costs, and show you how working with the right PCB assembly companies can make all the difference. By the end of this article, you’ll be equipped with everything you need to take control of your PCB assembly costs and stay ahead of the competition.

👉 Looking to save money on PCB assembly? Click here for a free consultation

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

Why Is PCB Assembly So Expensive?

PCB assembly costs can be broken down into several key factors, including:

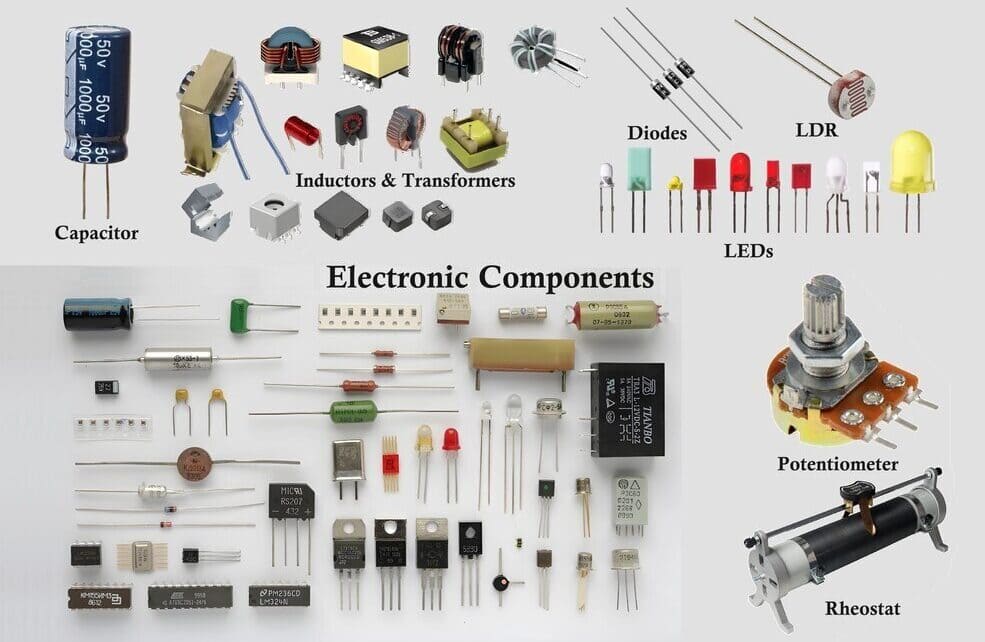

- The cost of high-quality circuit board components like capacitors, resistors, and integrated circuits.

- Labor-intensive assembly processes, especially in regions like the USA or Europe where wages are higher.

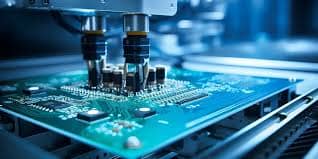

- Advanced techniques like SMT assembly, which require expensive machinery and skilled workers.

- The complexity of your design—more layers and custom components drive up the cost.

- Small production runs, which incur higher per-unit costs due to setup and tooling fees.

- Supply chain disruptions, which can cause raw material costs to skyrocket.

💡 Pro Tip: The first step to lowering costs is understanding these drivers and identifying where adjustments can be made.

What Drives Up PCB Assembly Costs?

- Material Costs Materials like FR-4 laminates, copper traces, and surface finishes add significant costs to your PCB board price. For advanced boards (e.g., HDI or high-frequency designs), the cost of specialized materials can be even higher. Did You Know? Non-standard circuit board components (like custom ICs) are harder to source and often come with hefty price tags. Switching to widely available components can save you a lot of money. Pro Tip: Ask your PCB assembly manufacturer if they can recommend equivalent standard components to save costs.

Labor Costs

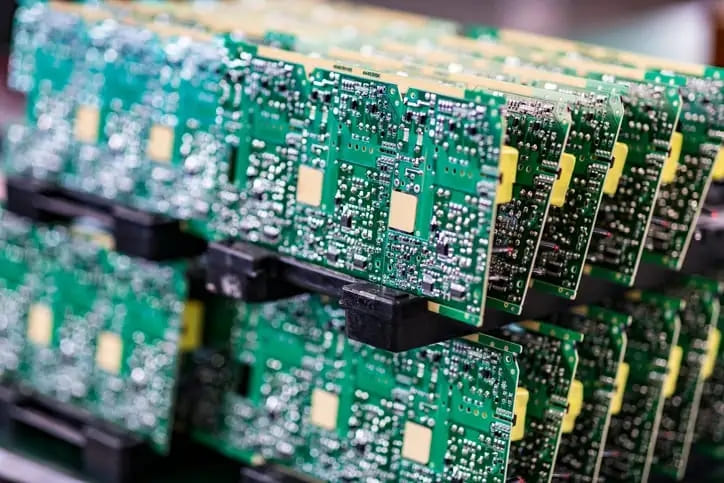

Skilled technicians are required for assembly, soldering, and testing in the PCB assembly process. These labor costs are significantly higher in regions like the USA or Europe compared to countries like China.Fun Fact: The growing use of automation in PCB assembly services has reduced labor costs for high-volume production runs, but smaller batches still require manual work.

👉 Want to reduce labor costs? Request a quote from our affordable assembly team.

Small Production Runs

Ordering only 10 or 20 boards? Be prepared for higher per-unit costs. This is because many PCB assembly companies charge setup fees for programming machines, creating stencils, and tooling, regardless of the batch size.Example: If a setup costs $500 and you order only 10 PCBs, that’s $50 per board in setup fees alone. However, if you order 100 boards, the setup cost drops to just $5 per board.

Pro Tip: Plan your production in larger batches to spread out setup costs and reduce your overall PCB board price.

Advanced Technology

SMT assembly (surface mount technology) is widely used for modern PCB boards because of its speed and precision, but it’s not cheap. High-precision SMT machines can cost millions of dollars to purchase and maintain, and the expense is passed on to you.Similarly, advanced boards like multilayer or HDI PCBs require sophisticated processes like laser drilling and automated inspection, further increasing costs.

How to Save Money on PCB Assembly Costs

Now that we’ve covered why PCB assembly is expensive, let’s talk about how you can bring those costs down.

- Optimize Your PCB Design

- Simplify the layout: Reducing layers and eliminating unnecessary components can significantly lower costs.

- Use standard components: Opt for commonly available sizes and specs to avoid custom manufacturing fees.

- Optimize the footprint: A smaller PCB size can reduce material usage and waste.

👉 Need help optimizing your design? Talk to our design experts today.

- Work with Cost-Effective Manufacturers

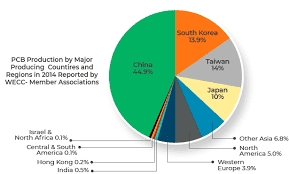

- PCB manufacturers in China are often the most affordable option, with streamlined production processes and competitive pricing.

- Look for certifications like ISO 9001 to ensure quality without compromise.

Internal Link: Learn more about choosing the right PCB supplier.

Leverage Pre-Sampling

Pre-sampling involves ordering a small batch of boards to test their functionality and catch design flaws early. This prevents costly rework during mass production and ensures you don’t waste money on materials or assembly.Example: One client saved 25% of their PCB assembly manufacturing costs by spotting and fixing a critical design flaw during pre-sampling.

👉 Want to save money on prototypes? Request your free pre-sample quote now.

- 4.Bulk Purchasing

When you buy components in bulk, you benefit from economies of scale, reducing the cost of circuit board components like resistors, capacitors, and connectors.

Pro Tip: Coordinate with your manufacturer to take advantage of bulk discounts for materials.

Why Choose Us?

When it comes to PCB assembly services, we stand out for several reasons:

- Competitive Pricing: Our partnerships with PCB manufacturers in China and globally allow us to offer unbeatable pricing.

- Fast Turnaround: Get your boards delivered in days, not weeks.

- Guaranteed Quality: Every board is inspected to meet the highest standards.

👉 Start saving today! Click here to get a custom quote.

Case Study: How We Helped a Client Save 30% on PCB Assembly

One of our startup clients came to us with a high-budget PCB design. After a thorough review, we helped them:

- Switch to standard circuit board components, saving $5,000 on parts.

- Simplify their design, cutting unnecessary layers and reducing the PCB size.

- Partner with a cost-efficient pcb manufacturer in China, saving an additional 30%.

Result? The client launched their product ahead of schedule and under budget.

👉 Want results like this? Contact us now.

Frequently Asked Questions

Wave soldering is most cost-effective for large production runs, while manual soldering is better for small batches.

Use standard components, negotiate bulk pricing, and optimize your design for efficiency.

SMT (surface-mount technology) involves placing tiny components directly onto a PCB, allowing for compact, high-speed designs.

Pre-sampling catches design flaws early, saving you from costly rework in mass production.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverCall to Action: Start Saving on PCB Assembly Today!

Stop overpaying for PCB assembly. Whether you need prototypes or full-scale production, we can help you reduce costs without compromising on quality.

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!