Quick Leads

Why Turnkey PCB Assembly Services Can Revolutionize Your Business

In today’s highly competitive manufacturing world, companies are always looking for ways to improve efficiency, reduce costs, and maintain the highest quality standards. For electronics manufacturers, one of the most critical steps in the process is assembling PCBs. However, managing the complexities of sourcing components, coordinating production, and testing can be time-consuming and challenging.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

This is where turnkey PCB assembly services come into play. When you work with a turnkey provider, they handle everything from sourcing the components to testing the final product. This means you can focus on what you do best: innovating and growing your business. But why should you choose a turnkey PCB assembly service? Let’s dive into the top benefits this approach offers and how it can drive cost savings and operational efficiency.

Turnkey PCB assembly is a complete, one-stop solution that simplifies the PCB production process. Turnkey services save you time and money by doing everything from sourcing and assembling to testing your final product. This is especially good for electronics manufacturers who want to make their operations more efficient, improve communication, and get their products to market faster. If you’re a business owner, engineer, or procurement manager, you can benefit from turnkey PCB assembly services.

What is Turnkey PCB Assembly?

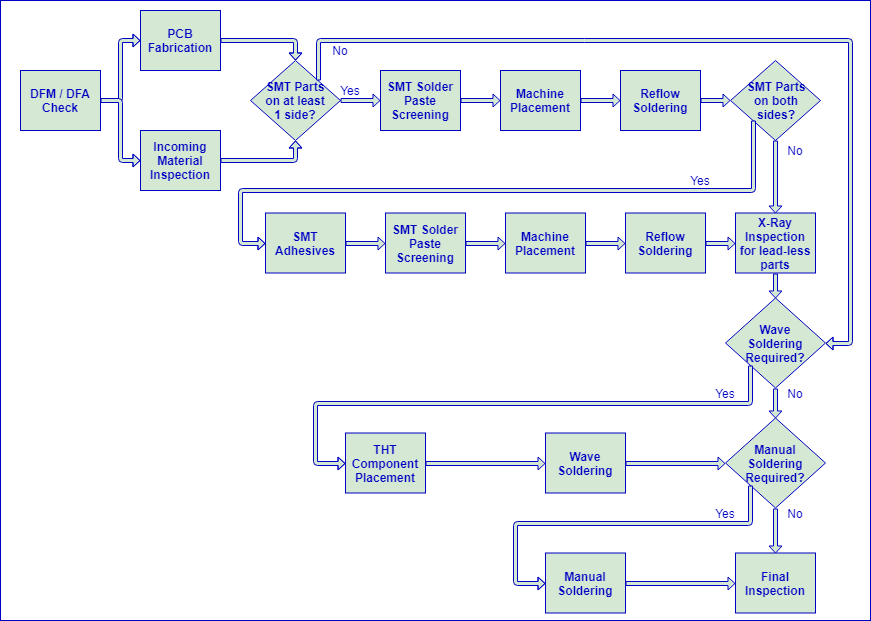

Turnkey PCB assembly is an all-inclusive service where a single provider takes responsibility for the entire PCB production process. This includes sourcing the necessary components, assembling the PCB, and performing all required testing before delivery. With turnkey services, businesses can consolidate multiple stages of production into a single, cohesive process, eliminating the need for dealing with multiple vendors.

Why PCBs Are Crucial for Electronics

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They connect various electronic components, such as resistors, capacitors, and microchips, in a compact and organized manner. Here are the key benefits of using PCBs in electronics:

-

Compact Design: PCBs minimize the need for wiring, saving space and reducing the complexity of designs.

-

Reliability: PCBs are built to handle electrical and thermal stress, ensuring long-lasting performance.

-

Cost-Effectiveness: By integrating multiple components into one board, PCBs reduce material costs and manufacturing time.

Making sure your PCB assembly is high quality is really important for electronics manufacturers because the performance and reliability of your final product depend on the quality of your PCB.

Turnkey PCB Assembly vs. Partial PCB Services: Which Is Better?

When you compare turnkey PCB assembly to partial assembly services, you need to understand the differences:

-

Turnkey PCB Assembly: This service involves a single provider managing all aspects of PCB assembly, including sourcing components, assembly, and testing. It ensures better coordination and consistency throughout the process.

-

Partial PCB Services: With partial services, a company might only handle certain parts of the production process, like putting components on the board or testing it, and then they’ll send other parts of the job to other vendors.

When you choose turnkey PCB assembly, you get the advantage of less complexity and more control over the whole process. This makes it perfect for businesses that want to be efficient and reliable.

Key Benefits of Turnkey PCB Assembly

1. Reduced Complexity with a Single Provider

When you have to deal with a bunch of different vendors for different parts of the PCB assembly process, it can introduce delays and miscommunication. Turnkey services solve these problems by putting all of the tasks under one provider, making it easier to manage your project.

2. Faster Time-to-Market

A significant advantage of turnkey PCB assembly is the speed it offers. Since one provider handles the entire process, you eliminate the delays that typically occur when coordinating between multiple vendors. This leads to a quicker time-to-market, giving you a competitive edge.

3. Improved Quality Control

Turnkey providers implement rigorous quality control measures throughout the assembly process. Since the same team is responsible for sourcing, assembly, and testing, the chances of errors or incompatibility are greatly reduced. Comprehensive testing ensures that the final product meets all functional and durability standards.

4. Streamlined Communication

When one provider handles all the production steps, communication is easier. You’ll have one point of contact, reducing misunderstandings and ensuring that any issues are addressed quickly.

5. Cost Savings

Even though you have to spend more money up front, you save money in the long run. Turnkey assembly can save you money by reducing suppliers you have to deal with and the amount of administrative work you have to do. Moreover, bulk purchasing and supplier relationships often lead to better pricing on components.

How Turnkey PCB Assembly Helps Save Time and Money

Opting for turnkey PCB assembly can lead to significant time and cost savings in several ways:

-

Consolidated Vendors: When you deal with one vendor for everything, it makes your life easier and saves you money on buying, shipping, and logistics.

-

Reduced Lead Times: When you consolidate services, you can get your product to market faster.

-

Lower Overhead Costs: Turnkey providers handle all the buying and coordinating, so you don’t have to. This saves you time and money because you don’t have to deal with a bunch of different suppliers.

Is Turnkey PCB Assembly Cost-Effective for Small Business?

Many small businesses hesitate to invest in turnkey services due to concerns about costs. However, turnkey PCB assembly can be especially beneficial for smaller operations. Here’s why:

-

Scalability: Even for small runs, turnkey services offer economies of scale that reduce per-unit costs.

-

No Need for In-House Expertise: Small businesses often lack the in-house expertise to manage complex PCB assembly. A turnkey solution provides access to specialized knowledge without the need to hire additional staff.

-

Time Savings: When you outsource the entire assembly process, you can focus on other things you need to do to grow your business.

How Turnkey PCB Assembly Reduces Lead Time

Turnkey PCB assembly significantly shortens lead times by:

-

Streamlining Communication: When you only have one person to talk to, you can get answers and make decisions faster.

-

Efficient Procurement: Turnkey providers can get parts faster because they already know who to call and they can buy more stuff at once.

-

Faster Testing and Quality Assurance: Since the same people who make the PCBs also test them, they can find problems faster and make sure the PCBs works right.

What Are the Key Challenges of Turnkey PCB Assembly?

Despite its many benefits, turnkey PCB assembly has a few potential drawbacks:

-

Finding a Reliable Provider: Some turnkey providers are better than others, so you need to find a good one.

-

Upfront Investment: You might have to spend more money up front than you would if you did it yourself or used a bunch of different people, but turnkey services can save you money in the long run.

-

Complexity of Design: Some really complicated circuit boards need special people to make them, and some turnkey people can’t do that.

But even though there are some problems, turnkey PCB assembly is still a good idea because it helps you make PCB faster, saves you money, and makes sure your PCB works right.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverConclusion

Turnkey PCB assembly is a way to make your stuff faster and easier. By managing the entire production cycle, from sourcing components to final testing, turnkey providers save you time, reduce costs, and improve product quality. Whether you’re a small business or a large enterprise, turnkey PCB assembly can help you stay competitive in a fast-paced market.

Get in touch today to learn how our turnkey PCB assembly services can optimize your manufacturing process and drive cost savings for your business!

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!