Quick Leads-PCBA

Turnkey solutions from PCB manufacturing to testing.

sales@unitcircuits.com

Choosing Between 0402 and 0603 Isn’t Just About Size

Choosing between 0402 and 0603 SMD components isn’t just a size issue—it’s a strategic decision that affects cost, performance, and manufacturability. Many engineers struggle with balancing board density, power ratings, and soldering challenges. This article explores real-world design trade-offs and offers expert guidance backed by our advanced PCB assembly capabilities.

What’s the Actual Difference Between 0402 and 0603 SMD Components?

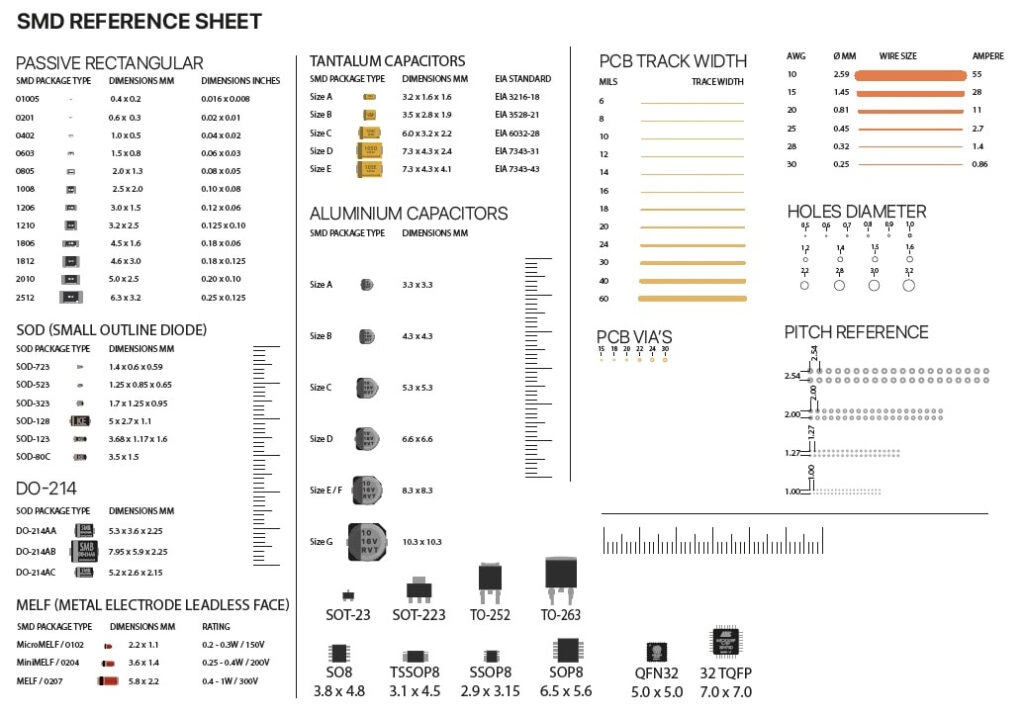

The key difference between 0402 and 0603 SMD components lies in their physical size and performance characteristics. 0402 (1.0mm × 0.5mm) components are more compact, making them ideal for space-constrained, high-density PCB layouts. 0603 (1.5mm × 0.8mm), on the other hand, offers better mechanical strength, easier assembly, and higher power ratings. Choosing between them depends on factors like circuit density, thermal requirements, and manufacturing capabilities. For a deeper understanding of SMD passive components, check out this comprehensive guide by Analog Devices.

Let’s break down the technical, manufacturing, and sourcing aspects to help you make the best decision for your next PCB project.

Does SMD Capacitor Size Matter in PCB Design?

Yes, SMD capacitor size has a direct impact on electrical behavior and layout. Larger capacitors like 0603 typically provide:

Higher capacitance values

Better voltage tolerance

Lower ESR (Equivalent Series Resistance)

Smaller capacitors (like 0402) have the advantage of space-saving but may suffer from derating in harsh conditions, especially in high-frequency RF circuits. This is critical in designs with tight tolerances or signal integrity constraints. 👉 Learn more about capacitor derating from KEMET’s engineering blog.

Engineers must also account for thermal behavior, as smaller packages dissipate heat less efficiently—impacting both performance and reliability in dense layouts.

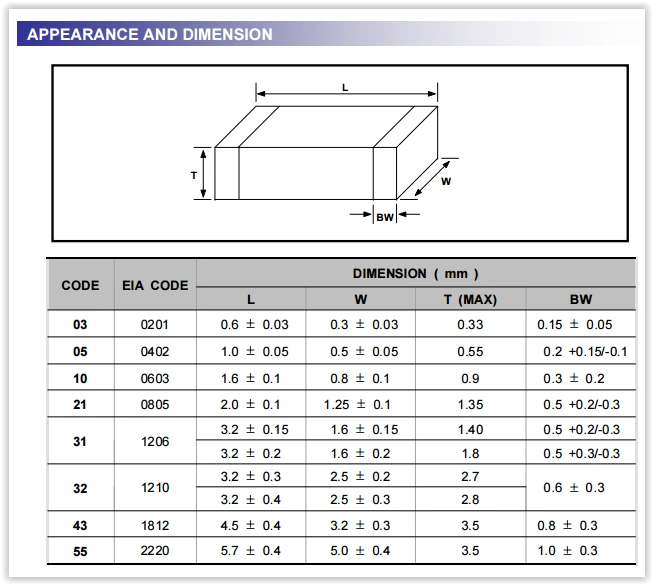

0402 vs 0603: Size Comparison and Dimensions in mm

| Package | Imperial Code | Metric (mm) | Area |

|---|---|---|---|

| 0402 | 0.04” x 0.02” | 1.0 × 0.5 | 0.5 mm² |

| 0603 | 0.06” x 0.03” | 1.5 × 0.8 | 1.2 mm² |

Despite their similar appearance, the 0603 footprint is more than double that of the 0402. This becomes significant when placing hundreds of components on compact PCBs.

This difference directly impacts:

Routing space

Component density

PCB layer count

Use this long-tail keyword opportunity: 0402 vs 0603 dimensions in mm.

What is SMD 0402 Best Used For?

SMD 0402 components are ideal for:

Smartphones

Wearables

High-frequency RF modules

Space-constrained modules like IoT nodes

Their small size allows for high-density PCB layouts, crucial when designing products where board real estate is extremely limited. But this comes with manufacturing caveats:

Tighter placement tolerances

Higher risk of tombstoning

More sensitive to thermal variation

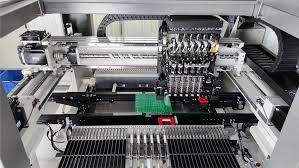

We often recommend 0402 only for experienced assembly houses using high-precision SMT equipment.

What is the SMD Code 0603?

The term 0603 refers to the size code of a component: 0.06 inches by 0.03 inches. This size is widely supported by automated pick-and-place systems and provides:

Better mechanical durability

Wider selection of resistor/capacitor values

Better performance under thermal stress

0603 remains the industry sweet spot for general-purpose applications. It’s often favored in:

Consumer electronics

Industrial controls

Automotive-grade modules

The sweet spot in 0402 vs 0603 which to use comes down to balancing performance vs space.

Difference Between 0402 and 0603 in Assembly

📌 PCB Assembly Process Factors:

| Factor | 0402 | 0603 |

|---|---|---|

| Pick & Place Accuracy | High | Moderate |

| Tombstoning Risk | Higher | Lower |

| Reworkability | Difficult | Easier |

| Solder Volume Tolerance | Tight | More forgiving |

Soldering 0402 requires greater control over reflow temperature and solder paste volume, making it less suitable for low-cost manufacturing runs without proper process control. 👉 The SMTA offers a great breakdown of 0402 vs 0603 soldering practices here.

In our lead-free soldering service with component sourcing, we often advise customers to move from 0402 to 0603 when the application allows.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

sales@unitcircuits.com

Which Should You Use – 0402 or 0603?

Here’s a decision guide:

| Requirement | Recommended Package |

|---|---|

| High component density | 0402 |

| Higher current/power | 0603 |

| Lower assembly cost | 0603 |

| Greater mechanical reliability | 0603 |

| IoT/compact modules | 0402 |

We often assist customers balancing 0402 vs 0603 assembly cost using DFM (Design for Manufacturability) reviews—a service included in all our production quotes.

Industry Pain Points: High-Density PCB Layout and Miniaturization Pressure

The pressure to fit more features into smaller spaces has created these industry challenges:

-

Layout congestion: High signal density leads to routing headaches.

-

Assembly defects: Miniaturized components suffer from higher failure rates if the process isn’t optimized.

-

Component sourcing: 0402 components are more prone to counterfeit issues due to global demand.

-

Inspection difficulty: Visual inspection and testing is harder with 0402.

Our Solution:

-

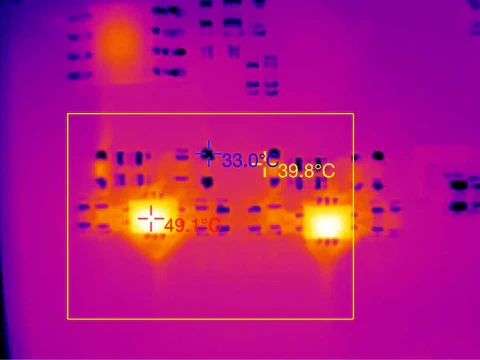

We use AOI & X-ray inspection for all fine-pitch boards

-

Component sourcing only from authorized channels

-

Thermal profiling tailored for micro-sized packages

This is what makes us a sustainable electronics manufacturing partner – UnitCircuits.

How Our PCB Assembly Services Solve These Challenges

We help engineering teams and purchasing managers overcome key hurdles:

✅ RoHS-compliant PCB assembly from China – we meet EU RoHS requirements with our lead-free PCB process.

✅ Advanced SMT assembly – capable of placing 01005 to 1206 with ±25μm accuracy.

✅ Component sourcing transparency – you get full traceability and original datasheets with every BOM order.

✅ Free Design Feedback – We review 0402 vs 0603 PCB design choices to optimize cost, performance, and yield.

0805 vs 0603 vs 0402: Scaling the Trade-Off Pyramid

Designers often wonder how small is too small. Here’s the breakdown:

| Package | Advantages | Disadvantages |

|---|---|---|

| 0805 | Highest power rating, easy to handle | Consumes more board space |

| 0603 | Balance of size, performance, cost | Less optimal for dense layouts |

| 0402 | Saves space, needed for IoT/RF | Requires precision, harder to rework |

Use 0805 vs 0603 vs 0402 as a long-tail H2 for extra traffic.

RoHS-Compliant PCB Assembly from China: What to Look For?

Before you outsource to a Chinese PCB house, verify:

-

✅ RoHS & REACH compliance

-

✅ Lead-free process capabilities

-

✅ X-ray inspection for BGA & 0402

-

✅ DFM review for each BOM upload

-

✅ Experience with miniaturized components

At UnitCircuits, we offer all of the above as part of our commitment to sustainable electronics manufacturing.

FAQs

1. What is a 0402 package in electronics?

A 0402 package refers to a Surface-Mount Device (SMD) component with dimensions of 0.04 x 0.02 inches (1.0 x 0.5 mm). These tiny components are often used in space-constrained PCB designs such as wearables and smartphones. Due to their small size, they require high-precision assembly and are more prone to placement issues like tombstoning.

2. Is 0201 the same size as 0603?

No, 0201 and 0603 are different SMD package sizes. 0201 (0.02” × 0.01”) is much smaller than 0603 (0.06” × 0.03”). While 0201 is used in ultra-compact electronics like RF modules, 0603 is easier to assemble and offers better power and thermal performance, making it suitable for industrial and consumer electronics.

3. What is the typical wattage rating of a 0402 resistor?

Most 0402 resistors are rated for 1/16 watt (0.0625W). However, this may vary slightly depending on the manufacturer and material. When designing high-density PCBs, it's important to confirm wattage ratings in the datasheet, especially for thermal-critical circuits.

4. What does 0603 mean in electronics?

In electronics, "0603" refers to the size of an SMD component—0.06 inches by 0.03 inches (1.5 mm × 0.8 mm). It’s one of the most commonly used sizes for resistors and capacitors in general-purpose PCB designs. 0603 components offer a good balance of power, cost, and manufacturability.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion:Your Design is Only as Good as Its Execution

Choosing the right SMD size like 0402 or 0603 is about balancing electrical specs, layout space, and cost. Our expert PCB assembly services ensure that your design is not only functional but also manufacturable and reliable. Ready to optimize your next board? Let’s build it right.

Save on your next PCB project?

Claim $100 OFF your order today.

sales@unitcircuits.com

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

sales@unitcircuits.com

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

sales@unitcircuits.com

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!