Quick Leads

How to Control PCB Assembly Costs: 10 Key Factors for Affordable Production

Controlling PCB assembly costs is a big deal for electronics manufacturers who want to be efficient without sacrificing quality. The more complicated your design is and the more choices you make about materials, the more it costs. But with good planning and smart strategies, you can save money and still have a smooth production run.

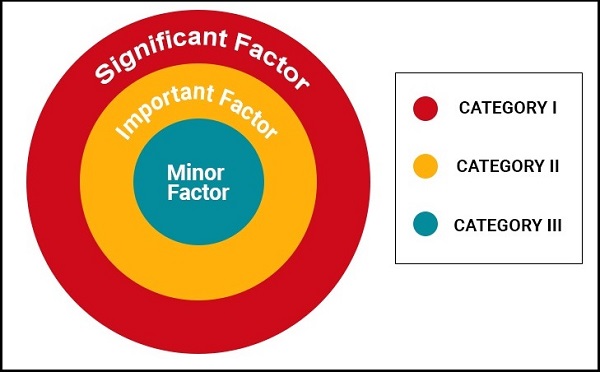

The key factors to control PCB assembly costs include how complicated your design is, what kind of components you pick, how big your board is, what kind of soldering you use, and what kind of materials you use.

Other things that affect cost are how much you pay your people, how many boards you’re going to build, how fast you want them, and how you’re going to test them. If you optimize all those things, you can save money and still get a good-quality board.

What Are the Key Cost Drivers for PCB Assembly?

The cost of putting your PCB together depends on how big it is, what kind of material you use, what kind of components you pick, and how much you pay your people. The more complicated your design is, the more components you have, the more layers you have, and the longer it takes to put it together. All of those things cost more money.

💡 Looking for full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

1.How Design Complexity Directly Impacts PCB Assembly Costs

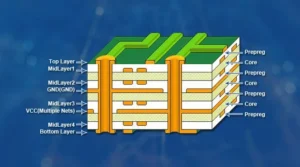

- Layer Count:Each additional layer you add to your board increases the cost by about 30% to 40%. After that, the cost goes up, but you don’t get as much in return.

- Drill Holes:The more holes you have, the more material you use, and the longer it takes to process your board.

- Simplified Circuits: If you can make your design less complicated, you’ll save time putting it together and you’ll get it done faster.

2.Smart Component Choices: Reduce BOM Costs Without Sacrificing Quality

- High-Value Components:If you use BGAs or specialized ICs, your bill of materials (BOM) is going to be a lot higher.

- Standard Components: If you use parts that everybody has, you’ll save money.

- Multiple Suppliers:If you have a couple of different places you can buy your parts from, you can get better prices and make sure you always have what you need.

BOM accuracy directly affects sourcing efficiency and final pricing.

3.PCB Size and Shape: How They Influence Costs

Factor | Low-Cost Option | High-Cost Option | Impact on Costs |

PCB Material | FR-4 | Rogers | Rogers increases costs by ~30% |

Assembly Type | SMT | Through-Hole | Through-hole is more labor-intensive |

Lead Time | Standard (2-3 weeks) | Expedited (24-48 hours) | Expedited orders increase costs by 20-30% |

4.Which Soldering Process Saves the Most Money?

- Wave Soldering: Good for through-hole components; cheap for simple designs.

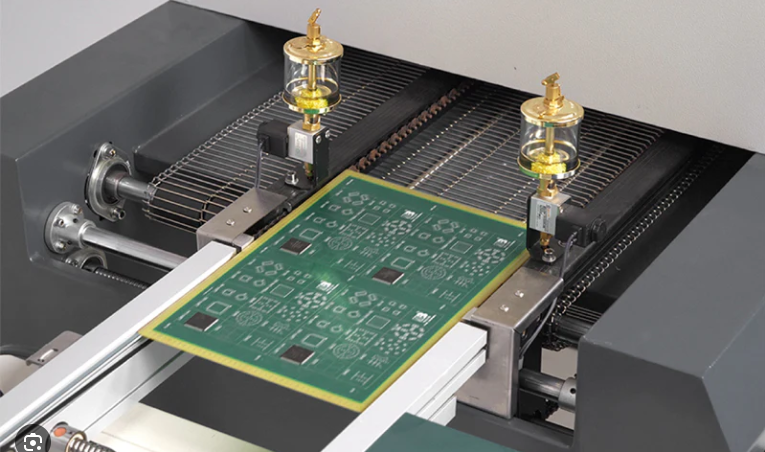

- Reflow Soldering:Perfect for surface mount components and when you’re using a machine to put your board together.

- Selective Soldering:Good for boards that have both surface mount and through-hole parts, but it costs more money because you have to pay somebody to do it.

5.Material Selection: Balancing Performance and Budget

-

FR-4 vs. Rogers:FR-4 is the standard, and it’s cheap. Rogers is fancy and it costs more money.

-

Thermal Management Materials: Improve durability but increase production costs.

6.How Labor Costs Vary by Region

-

Lower Labor Costs: Found in China and Eastern Europe.

-

Higher Labor Costs: Seen in the U.S. and Western Europe.

-

Automation: Reduces labor costs and boosts production efficiency.

7.Testing and Quality Control: Worth the Extra Cost?

-

In-Circuit Testing (ICT): Ensures each component works properly.

-

Automated Optical Inspection (AOI): Detects defects during assembly.

-

Functional Testing: Verifies board performance, though it requires more time and equipment.

8.How Order Volume Impacts PCB Assembly Costs

-

Economies of Scale: Larger orders reduce per-unit costs through shared setup fees.

-

Batch Production: Distributes fixed costs across multiple units for better cost-efficiency.

9.How Lead Time Affects Assembly Costs

-

Expedited Orders: Increase costs with overtime and added resource allocation.

-

Standard Lead Times: Cost-effective but require early planning.

10.Additional Services and Customization: Do They Add Value?

-

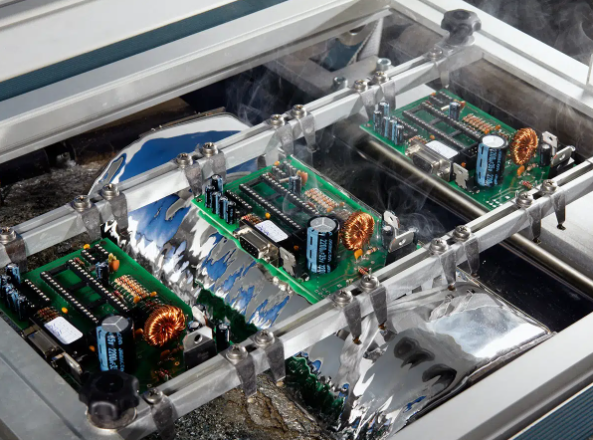

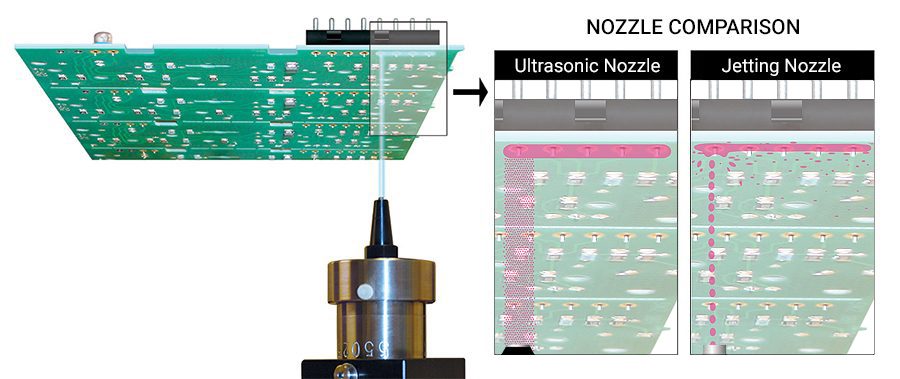

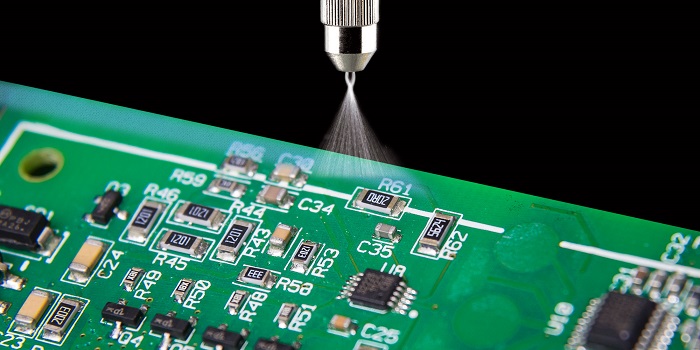

Conformal Coating: Provides protection but increases labor and material costs.

-

Industry Compliance: Meeting standards like IPC requires additional processes, raising expenses.

Key Takeaways

-

The more complicated your design is, the more choices you make about materials, and the faster you want your boards, the more it costs.

-

If you standardize your components and use turnkey suppliers, you can save money.

-

If you plan ahead and don’t have to pay extra to get your boards done faster, you’ll save money. If you do all those things, you’ll save money and you’ll get your boards done faster.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

Reflow soldering is perfect for surface mount components and when you’re using a machine to put your board together. That’s why it’s cheaper to do it when you’re making a lot of boards.

Work with suppliers who don’t have a minimum order quantity (MOQ) and put a bunch of different projects together to save money on setup.

Summary

To control costs, you have to design your board right, pick the right parts, and plan your production. You have to balance performance with cost. You have to be able to make a lot of boards and you have to be able to plan ahead. You have to use the same stuff all the time.

Need help sourcing affordable components or planning your next PCB project? Contact us for a free consultation today!

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

In this guide, we’ll explore what BGA is, its advantages and challenges, and how it compares to other packaging types like QFP and CSP.

Continue ReadingTop 10 PCB Assembly Manufacturers in Europe

In this guide, I’m going to show you the top 10 PCB assembly manufacturers in Europe. I’ll show you who they are, what they do, and why you should consider working with them.

Continue ReadingWhat Are PCB Conformal Coatings?

Discover everything you need to know about PCB conformal coatings: what they are, the different types, how to use them, and how to choose the right one for your application. This is the ultimate guide for engineers and electronics professionals.

Continue ReadingHow to Repair Circuit Boards

Have you ever opened up an electronic device and found a circuit board that needed repair, but you didn’t know where to start? Circuit board repairs can be intimidating, especially for beginners looking to do DIY circuit board repair at home.

Continue ReadingRELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!