Quick Leads

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

1. How to Fix Insufficient Hole Fill in Wave Soldering?

Causes:

- Improper preheat.

- Low solder pot temperature.

- Rapid conveyor speed.

Solutions:

- Adjust solder pot temperature: Ensure the solder remains at a proper viscosity.

- Optimize the preheat stage: Drive off moisture and enhance solder flow.

- Reduce conveyor speed: This gives the solder enough time to fill the holes thoroughly.

Pro Tip:

Top 5 Common Wave Soldering Defects and How to Fix Them

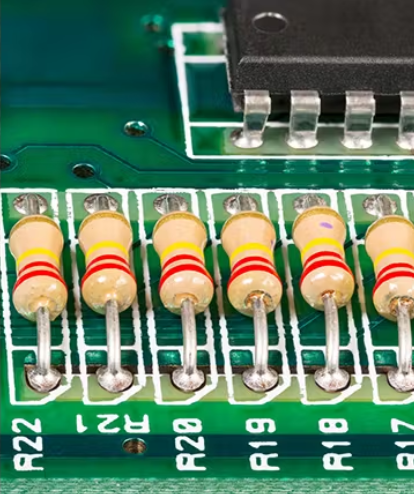

2. Prevent Solder Bridging: Tips for Wave Soldering Success

Causes:

- Close pin spacing.

- Low wave temperature.

- Excessive solder application.

Solutions:

- Use a proper solder mask design: Minimizes the likelihood of bridging.

- Increase wave temperature: Improves solder flow and prevents pooling.

- Ensure optimal flux application: Reduces surface tension, promoting even solder flow.

Pro Tip:

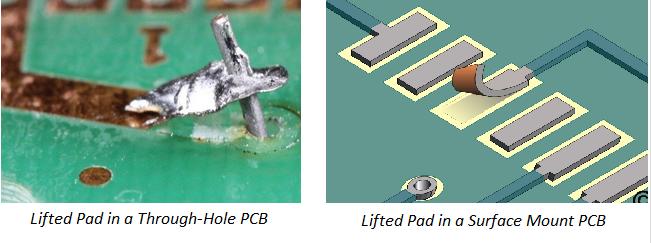

3. Causes of Lifted Components During Wave Soldering

Causes:

-

Insufficient flux.

-

Improper preheat.

-

Uneven wave pressure.

Solutions:

-

Ensure even flux application: Improves solderability.

-

Adjust preheat settings: Make sure your board and parts get hot enough before they go into the wave.

-

Verify wave uniformity: Consistent pressure across the entire board maintains component placement.

Pro Tip:

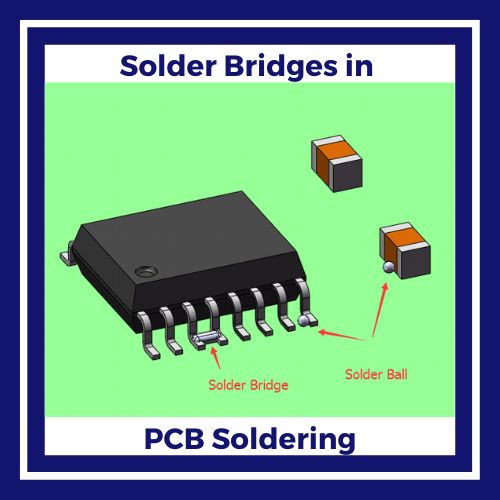

4. Preventing Solder Balling in PCB Wave Soldering

Causes:

-

Excess moisture in the flux.

-

Rapid cooling.

-

Excessive solder.

Solutions:

-

Thoroughly dry the PCB: Reduces moisture-related issues.

-

Adjust cooling rates: Prevents the solder from solidifying too quickly.

-

Monitor solder application: Ensure it stays within optimal levels.

Pro Tip:

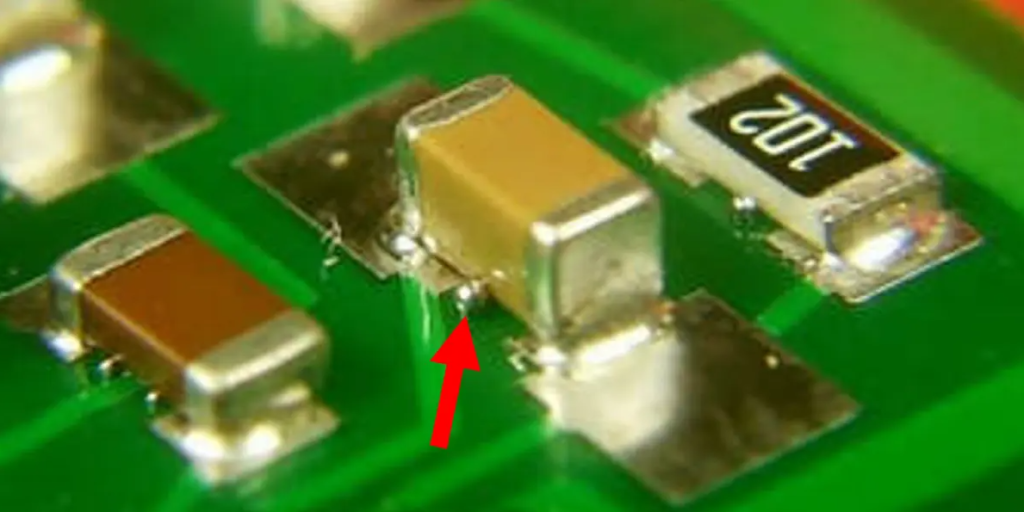

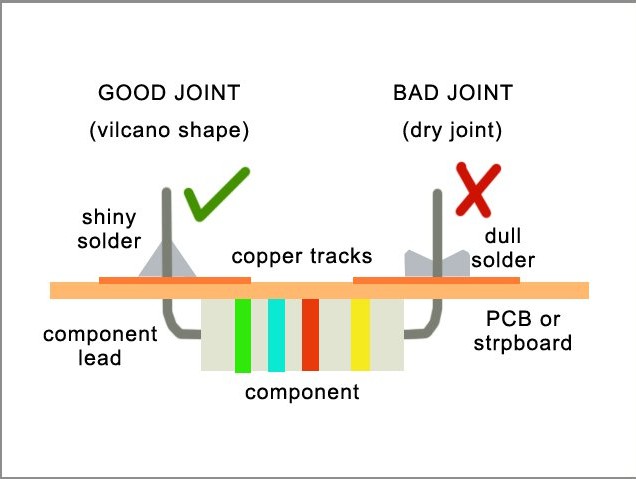

5. How to Prevent Cold Solder Joints in Wave Soldering?

Causes:

-

Insufficient heat.

-

Poor flux activity.

-

Incorrect wave parameters.

Solutions:

-

Increase wave temperature: Ensures adequate heat delivery.

-

Use a more active flux: Improves the wetting action of the solder.

-

Adjust dwell time: Allows the solder to properly bond to the components.

Pro Tip:

Summary Box for Quick Reference

|

Defect |

Quick Fix |

|

Insufficient Hole Fill |

Adjust solder temperature, optimize preheat, slow conveyor speed |

|

Solder Bridging |

Use proper solder mask, increase wave temperature |

|

Lifted Components |

Ensure even flux application, verify wave uniformity |

|

Solder Balling |

Dry PCB thoroughly, adjust cooling rates |

|

Cold Solder Joints |

Increase wave temperature, adjust dwell time |

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverFrequently Asked Questions (FAQ)

The best wave soldering temperature is usually between 240°C and 260°C, depending on the solder alloy you are using. Staying within this range will give you good flow and good joints.

To avoid cold solder joints, make sure your wave is hot enough, use a more active flux, and adjust the dwell time to get better heat transfer.

Solder balling is often caused by moisture in the flux or by cooling too fast. To prevent it, dry your boards really well before you solder them and adjust your cooling rates to allow for gradual solidification.

Need help dialing in your wave soldering process? Contact our experts for a consultation. Have a specific wave soldering challenge? Reach out for personalized advice!

Having trouble with wave soldering defects like bridging, cold joints, or lifted components? Above shows you the top 5 defects and solutions to improve your PCB assembly quality.

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!