Quick Leads

Master the 7 Essential IC Programming Methods for PCBA Processing

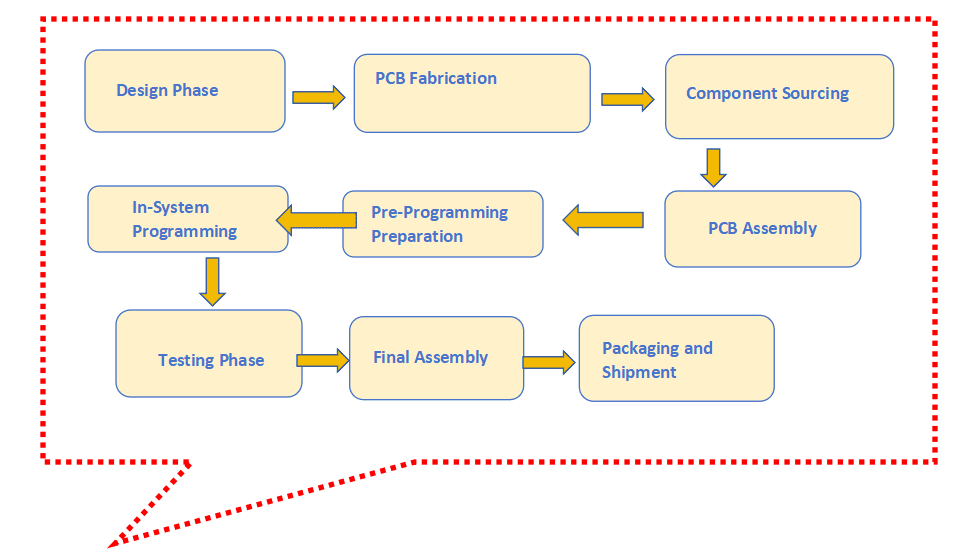

In electronics manufacturing, IC programming, also known as embedded firmware programming, is a critical part of modern Printed Circuit Board Assembly (PCBA). Proper IC programming ensures that software is integrated into Integrated Circuits (ICs) smoothly, which affects functionality, quality, and production efficiency.

This guide will explore seven essential IC programming methods, from in-circuit programming to boundary scan, along with actionable insights, emerging trends, and tools to streamline your production processes.

What Is PCB Programming?

PCB programming, also known as embedded firmware programming, is the process of putting software or firmware into Integrated Circuits (ICs) on a PCB. It makes sure that all the components work like they’re supposed to and makes your product more reliable.

Why It Matters:

-

Efficiency: Reduces time-to-market by programming firmware during assembly.

-

Quality: Ensures everything works before you ship it.

-

Cost Savings: Saves you money on debugging and rework.

The 7 Essential IC Programming Methods in PCBA

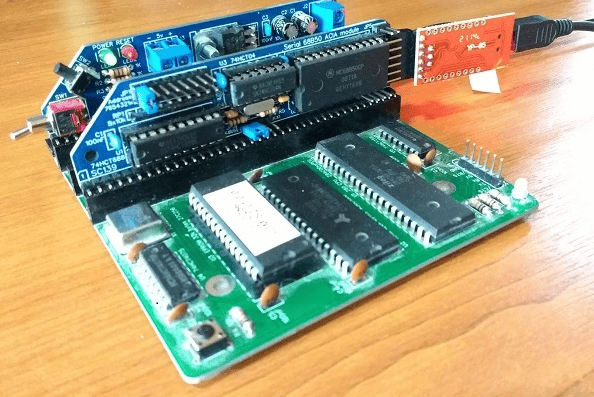

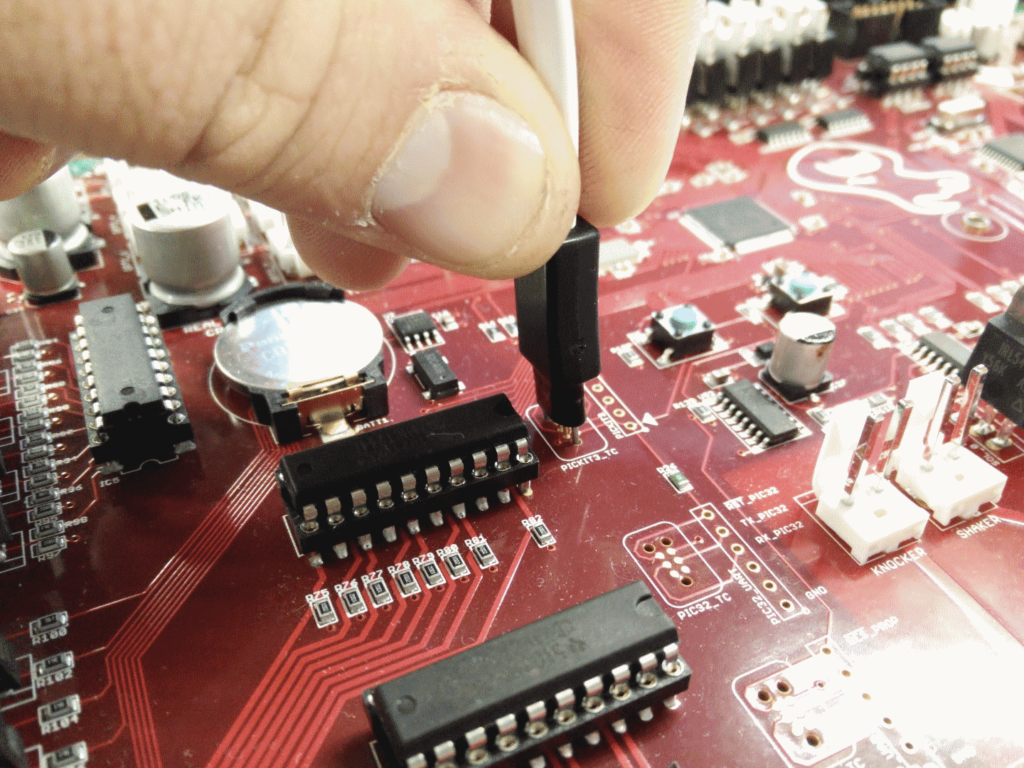

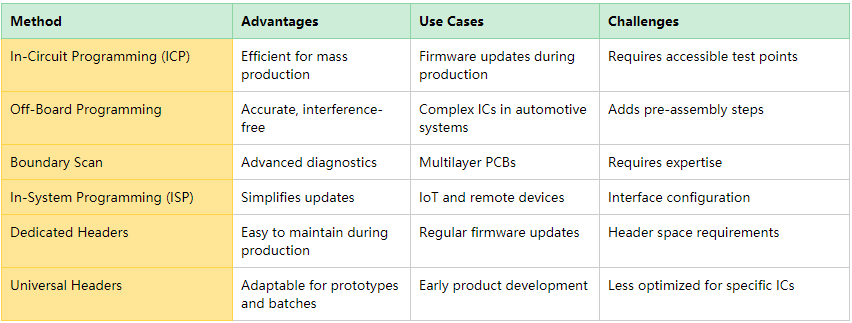

1. In-Circuit Programming (ICP): Making Mass Production Easier

In-Circuit Programming is when you connect programming tools to test points on the PCB. With this method, you can program without removing ICs.

-

Advantages:Great for mass production; good for debugging.

-

Use Case:Perfect for updating firmware in consumer electronics.

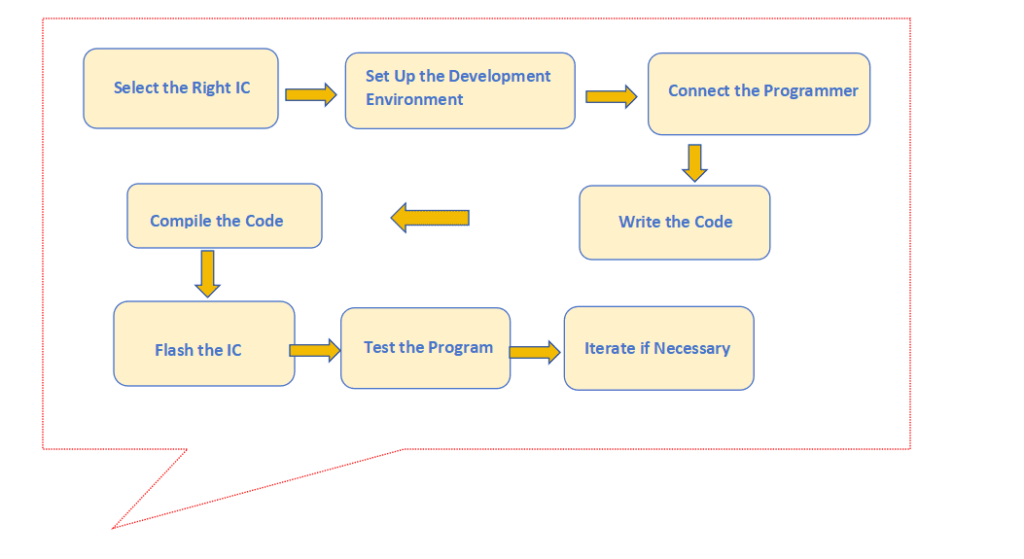

Example Workflow:

-

Find the test points on the PCB.

-

Connect programming tools like Segger J-Link.

-

Upload the firmware and make sure it works.

2. Off-Board Programming: Getting It Right Before Assembly

In off-board programming, you program the ICs before assembly using special sockets.

-

Advantages: Keeps you from messing up; makes sure you program everything right.

-

Use Case: Used for automotive applications that need really precise control systems.

-

Recommended Tools: Xeltek SuperPro or Data I/O FlashCore.

3. In-Socket Programming: A Great Way to Program ICs

You put the ICs in special sockets to program them. It works with a lot of different ICs and is really accurate.

-

Advantages: Works with all kinds of ICs; makes sure you program the firmware right.

-

Use Case: Programming microcontrollers for industrial automation systems.

-

Example: A robotics manufacturer programs memory chips to make sure the robots do what they’re supposed to do.

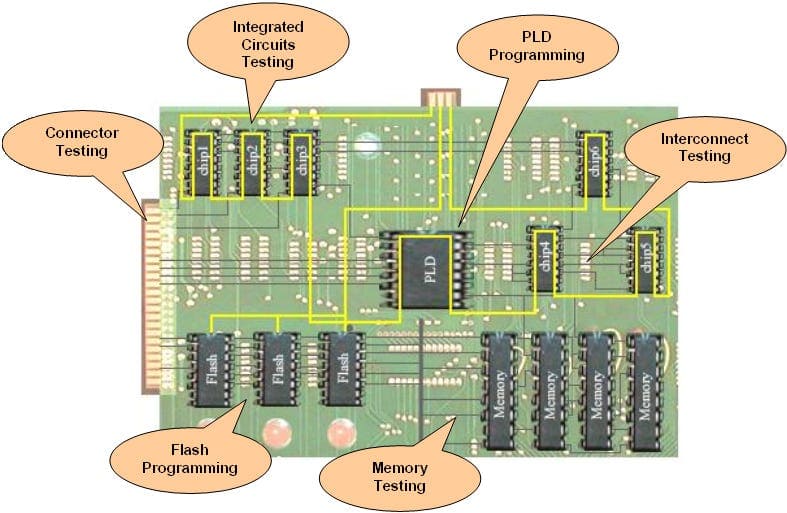

4. Boundary Scan: The Best Way to Test Multilayer PCBs

Boundary scan is when you use the built-in test stuff inside the ICs to program and test, even if you can’t get to the layers of the PCB.

-

Advantages: You don’t have to touch anything; it’s perfect for really dense PCBs.

-

Use Case: Debugging 5G network equipment with PCBs that have lots of layers.

-

Tools: XJTAG for fast diagnostics and programming.

Real-World Example:

A telecom company saved 30% on debugging by using boundary scan to test high-speed routers.

5. In-System Programming (ISP): Making It Easy to Update After Assembly

ISP is when you program the ICs after the PCB is assembled. It’s perfect for products that need firmware updates after they’re in the field.

-

Advantages: You can update stuff from far away; it makes things easier to take care of.

-

Use Case: You use it a lot with IoT devices and wearables.

-

Step-by-Step Checklist:

-

Set up the JTAG/SPI thing.

-

Make sure the firmware works with a test board.

-

Make sure the power stays on while you’re programming.

-

6. Dedicated Headers: The Best Way to Program in Production

Dedicated headers are built-in connectors for programming when you’re making a lot of something.

-

Advantages: Makes things go faster; easy to keep up with.

-

Use Case: Products that need regular firmware updates.

7. Universal Headers: Flexibility for Prototyping

Universal headers are versatile and can be used with a variety of IC types, making them perfect for prototyping and small-batch production.

-

Advantages:Cost-effective; you don’t have to set up multiple times.

-

Use Case: Early-stage IoT device development.

Key Advantages of IC Programming in PCBA

-

Improved Quality Control: Reduces errors before you deploy.

-

Production Efficiency: Firmware is embedded during assembly.

-

Cost Reduction: Minimizes debugging and rework costs.

Overcoming Programming Challenges

Compatibility Issues:

Make sure your programming tools match the IC specifications to prevent errors.

High-Density PCB Complexity:

Use boundary scan for multilayer PCBs.

Cost Concerns:

Invest in scalable tools like Microchip MPLAB ICD for long-term savings.

Practical Tools for IC Programming

Tool Recommendations:

-

Boundary Scan: Use XJTAG for diagnostics.

-

ISP: Opt for Segger J-Link for reliable in-system programming.

-

Off-Board Programming: Choose Xeltek SuperPro for high-volume accuracy.

For more information, visit below:

For more insights on Complete Guide on it, check out: IC Programming

Frequently Asked Questions (FAQs)

In-system programming happens after you’ve assembled your board, and in-circuit programming happens while you’re making your board.

I like universal headers because they work with all different kinds of chips.

You need things like JTAG programmers, dedicated sockets, and in-circuit testers.

Limited Time Offer:

Get $100 off your order TODAY!

Claim your $100 discount now – this offer won’t last long! Today ONLY!

Don’t miss this chance to save on your next project.

[Hurry! Only 50 discounts remaining!]

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverVisual Summary of IC Programming Methods

Streamline your PCBA process with expert IC programming services!

Contact us today for fast, reliable solutions tailored to your needs.

Request for Quote

RECENT POSTS

SMD Size Code Chart (2026) – Surface Mount Resistor & Capacitor Dimensions Explained

This article explains how to decode SMD size codes, compare imperial and metric measurements, and

The Hidden Cost of Cheap PCB Assembly: What Every Engineer Should Know Before Choosing a Manufacturer

Discover the real cost of cheap PCB assembly. Learn how our turnkey service with testing

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!