Quick Leads

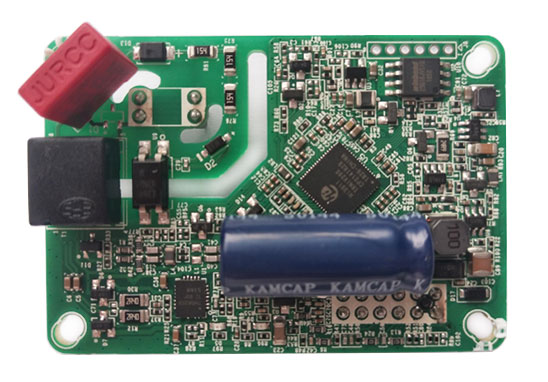

Top 8 Common PCB Assembly Problems and How to Fix Them

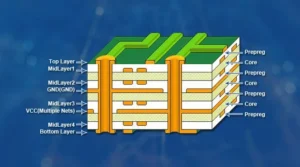

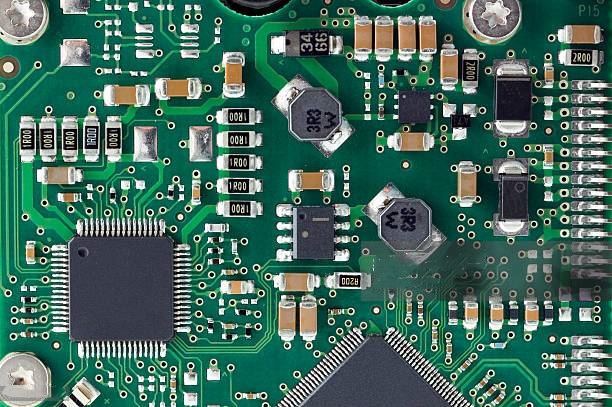

Printed Circuit Boards (PCBs) are the backbone of all modern electronics. But even a small assembly problem can lead to big functional problems, delays, and extra money in manufacturing.

Here are eight of the most common PCB assembly problems and how to fix them. This will help you make your assembly process smoother and keep your product quality high.

The most common PCB assembly problems include BOM issues, incorrect footprints, soldering defects, and poor thermal management. To fix these, ensure accurate BOM, proper design checks, and careful soldering processes.Fix these now to avoid expensive failures and make your production faster.

💡 Full-service PCB Assembly?

We offer turnkey solutions from PCB manufacturing to testing.

1. What are the errors in PCB assembly?

How to Fix:

To avoid these problems, make sure your design data is complete and right before you start assembly. Use a Design for Assembly (DFA) process to put your parts in the best places and keep them from running into each other. Do a thermal analysis to make sure heat goes where it needs to go.

2. BOM Problems

One of the most common problems is having the wrong Bill of Materials (BOM). If your BOM has mistakes, like missing parts or parts that aren’t right, you’ll have a hard time getting your boards made and they won’t work right.How to Fix:

3. Incorrect PCB Footprints

How to Fix:

4. Soldering Defects

How to Fix:

5. Thermal Issues

How to Fix:

6. Lack of Testability

How to Fix:

7. Inadequate Silkscreen Markings

How to Fix:

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliver8. Incomplete or Unclear Documentation

How to Fix:

Conclusion

🔧 Want to avoid these manufacturing issues with a trusted partner?

👉 See how our Turnkey PCB Assembly can help »

Request for Quote

RECENT POSTS

Understanding Ball Grid Array (BGA) Technology

Top 10 PCB Assembly Manufacturers in Europe

What Are PCB Conformal Coatings?

How to Repair Circuit Boards

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!