Quick Leads

What Are the Advantages of Using Aluminum Nitride (AlN) PCBs in Medical Devices?

Quick Summary of Benefits of AlN PCBs in Medical Devices:

- Superior Thermal Conductivity (170-200 W/mK) for optimal heat dissipation

- High Dielectric Strength for safe high-voltage operation

- Reduced Maintenance Needs thanks to effective thermal management

- Enhanced Reliability in high-stakes medical environments

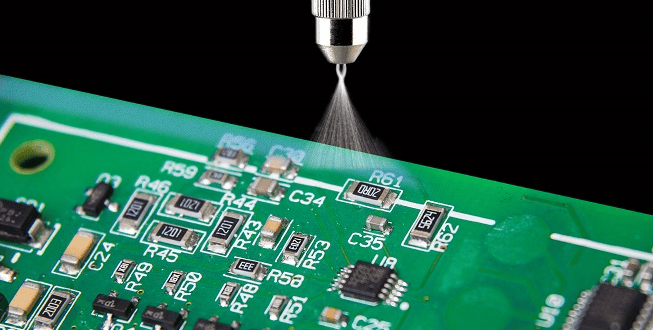

1. Technical Superiority of Aluminum Nitride PCBs

Thermal Conductivity

Electrical Insulation Properties

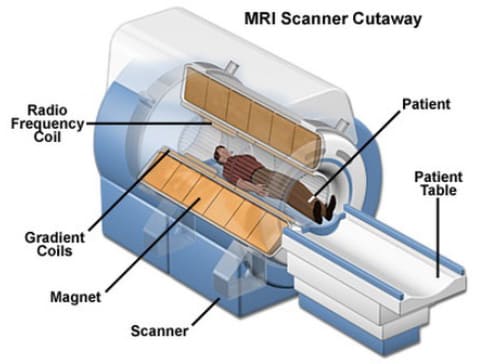

- Protection against electrical interference, vital for accurate imaging and monitoring devices.

- Stable performance in high-stakes settings, such as patient monitoring.

2. Why Aluminum Nitride PCBs Outperform Other Materials in Medical Devices

Material | Thermal Conductivity | Dielectric Strength | Ideal Applications |

Aluminum Nitride (AlN) | 170-200 W/mK | 15-20 kV/mm | High-power medical devices (e.g., imaging, therapy) |

FR4 | 0.3-0.4 W/mK | Moderate | General electronics |

Alumina (Al₂O₃) | 20-30 W/mK | High | Mid-range thermal applications |

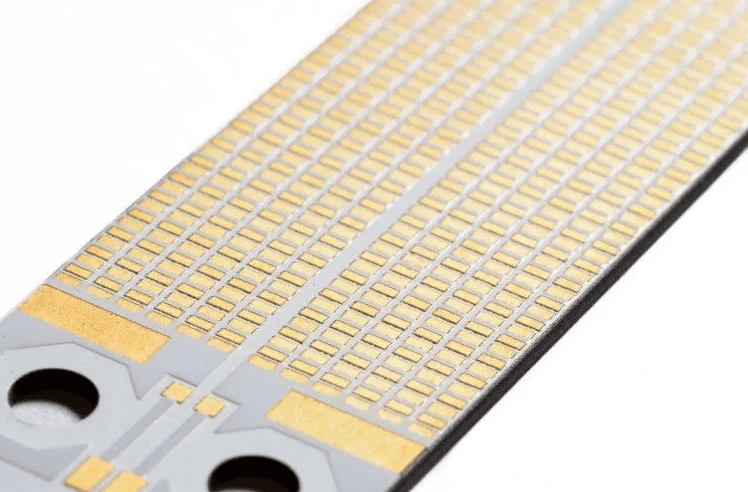

3. Real-World Examples: How AlN PCBs Improve Reliability in Medical Imaging and Diagnostic Equipment

Preventing Overheating

- Medical imaging devices benefit from Aluminum Nitride’s heat dissipation, which helps maintain image clarity and reduce the need for recalibration.

- Thermal therapy devices use AlN to maintain consistent heat levels, which ensures patient safety during treatments.

Reduced Maintenance Needs

Aluminum Nitride’s heat dissipation reduces wear on components and downtime, which is valuable for healthcare providers who need reliable, low-maintenance equipment.

4. Addressing Limitations with Practical Solutions

- Preserve AlN’s thermal and electrical properties even as environments change.

- Ensure consistent performance, particularly in critical medical devices.

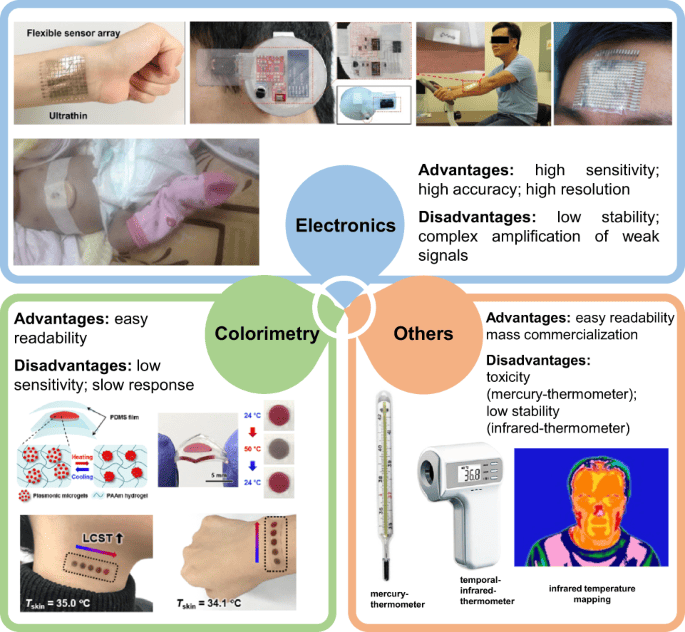

5. Future Trends in Aluminum Nitride PCB Technology for Medical Devices

- Enhancing thermal and moisture resistance for use in wearable and minimally invasive medical devices.

- Enabling the miniaturization of high-performance electronics for next-generation healthcare technology.

Pros and Cons of Aluminum Nitride in Medical Devices

|

Pros |

Cons |

|

High thermal conductivity |

Sensitive to moisture |

|

Excellent electrical insulation |

Higher cost compared to FR4 |

|

Reduced maintenance |

|

|

Enhanced reliability |

For more information, visit below:

Frequently Asked Questions (FAQs)

Thermal management prevents overheating, maintains device calibration, and extends the life of equipment.

Aluminum Nitride offers superior thermal conductivity and insulation compared to FR4 and Alumina, which makes it ideal for high-power applications.

Protective coatings and encapsulation prevent moisture from affecting AlN’s performance, which ensures long-term reliability.

Limited Time Offer:

Get $100 off your order TODAY!

Trusted by 100+ businesses worldwide

Trusted by 100+ businesses worldwide No hidden fees – transparent pricing

No hidden fees – transparent pricing Guaranteed quality with on-time deliver

Guaranteed quality with on-time deliverReal-World Case Study

Call to Action

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select the right transformer for SMPS, IoT, or relay control. Start designing smarter today.

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and delivery—and how turnkey EMS solutions protect your product and bottom line.

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!